Composite modified pregelatinized starch and preparation method thereof

A technology of pregelatinized starch and compound modification, applied in food preparation, food science, application and other directions, can solve the problems of complex preparation process, non-dispersible agglomerates, slow hydration rate, etc., and achieve the effect of simplifying the process and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

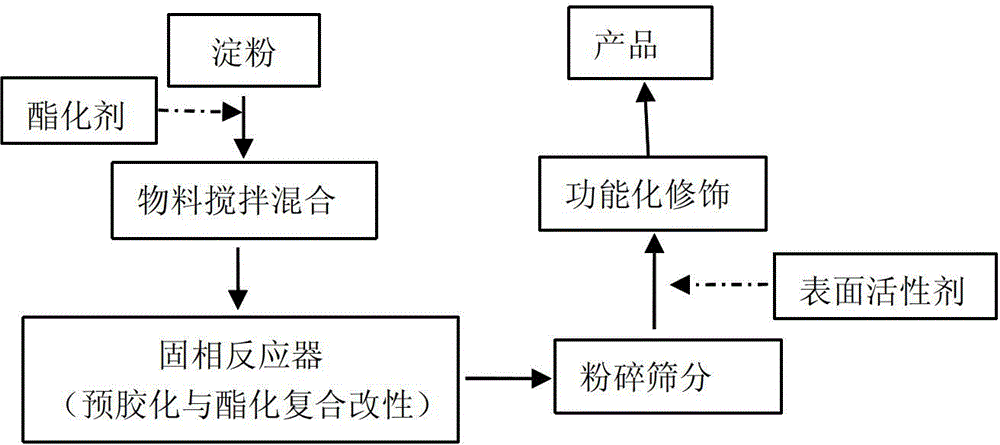

Method used

Image

Examples

Embodiment 1

[0022] (1) Stir and mix the materials: Add 97 parts of tapioca starch and 1.5 parts of stearic acid into the mechanical activation equipment, stir and mix at high speed for 10 minutes to obtain the mixed material;

[0023] (2) Compound modification of pregelatinization and esterification: mix the mixed material and the volume of pellets according to the ratio of 100g: 300ml, react in the ball mill reactor for 2.5h, and discharge the material for crushing and screening to obtain composite modified starch;

[0024] (3) Functional modification: 98.5 parts of composite modified starch and 1.5 parts of alkyl glycoside were mixed and reacted at high speed for 0.3 hours to obtain composite modified pregelatinized starch.

[0025] The prepared composite modified pregelatinized starch has a cold water solubility (30°C) of 68.5%, freeze-thaw stability ≥ 5, emulsification (absorbance value) ≥ 0.4, brewing property ≥ 85, and can be used as a food stabilizer and medicinal Accessories.

Embodiment 2

[0027] (1) Stirring and mixing of materials: Add 96 parts of cassava and corn starch mixture and 2 parts of palmitic acid into the mechanical activation equipment, stir and mix at high speed for 5 minutes to obtain the mixed material;

[0028] (2) Compound modification of pregelatinization and esterification: mix the mixed material and the heap volume of balls according to the ratio of 100g: 260ml, react in the ball mill reactor for 0.8h, and crush and sieve the material to obtain the compound modified starch;

[0029] (3) Functional modification: 98 parts of composite modified starch and 2 parts of alkyl glycoside were mixed, and the high-speed mixing reaction was carried out for 0.25 hours to obtain composite modified pregelatinized starch.

[0030] The prepared composite modified pregelatinized starch has a cold water solubility (30°C) of 37%, freeze-thaw stability ≥ 5, emulsification (absorbance value) ≥ 0.4, brewability ≥ 85, and can be used as a food thickener and filling...

Embodiment 3

[0032] (1) Stirring and mixing of materials: Add 99 parts of cornstarch and 0.5 parts of palmitic acid into the mechanical activation equipment, stir and mix at high speed for 5 minutes to obtain the mixed material;

[0033] (2) Compound modification of pregelatinization and esterification: mix the mixed material and the heap volume of the material ball according to the ratio of 100g: 250ml, react in the ball mill reactor for 0.5h, and discharge the material for crushing and screening;

[0034] (3) Functional modification: 99.5 parts of composite modified starch and 0.5 part of alkyl glucoside were mixed and reacted at high speed for 0.2 hours to obtain composite modified pregelatinized starch.

[0035] The prepared composite modified pregelatinized starch has a cold water solubility (30°C) of 18%, freeze-thaw stability ≥ 5, emulsification (absorbance value) ≥ 0.4, brewability ≥ 85, and can be used as a food thickener, filling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com