Low-damage fracturing fluid and fracturing method

A fracturing fluid and hydraulic fracturing technology, applied in chemical instruments and methods, earthwork drilling, and fluid production, etc., can solve problems such as damage to support belts, and achieve the effects of reducing damage, reducing dosage, and improving fracturing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

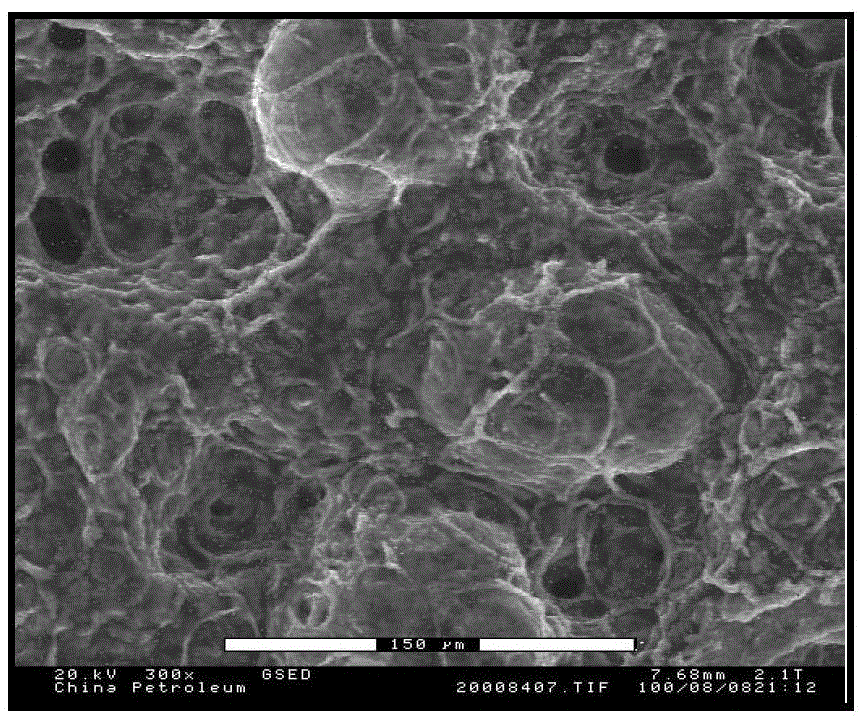

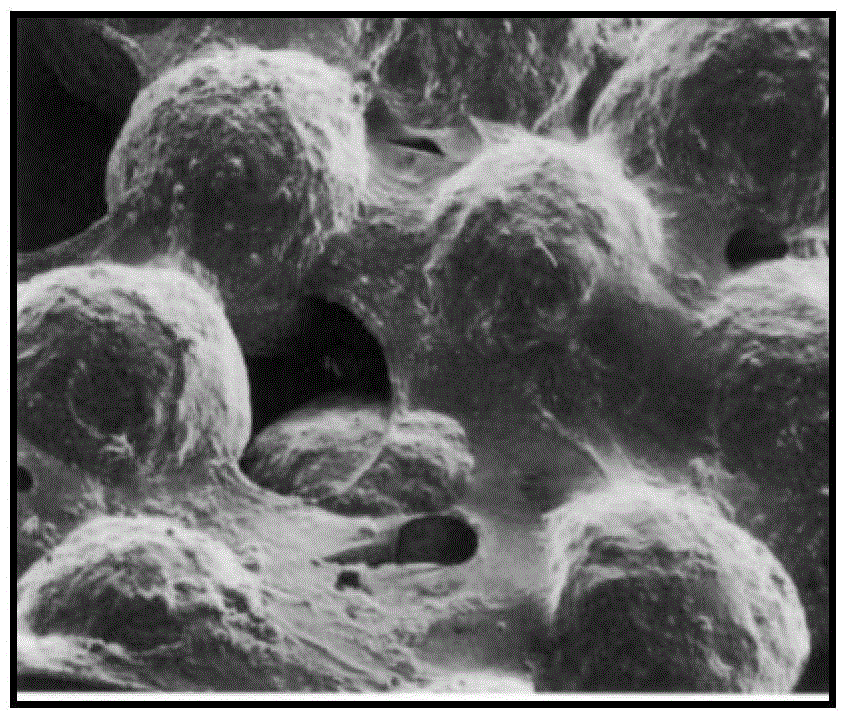

[0072] Example 1: Measuring proppant permeability in the laboratory

[0073] (1) Preparation of conventional guar gum fracturing fluid

[0074] Measure 2000ml tap water, add 4g hydroxypropyl guar gum (Jingkun Oilfield Chemical Technology Development Company), 0.5g citric acid (commercially available) and 40g Potassium Chloride (commercially available) successively under stirring condition, stir until Completely dissolved, thus making conventional guar gum fracturing fluid.

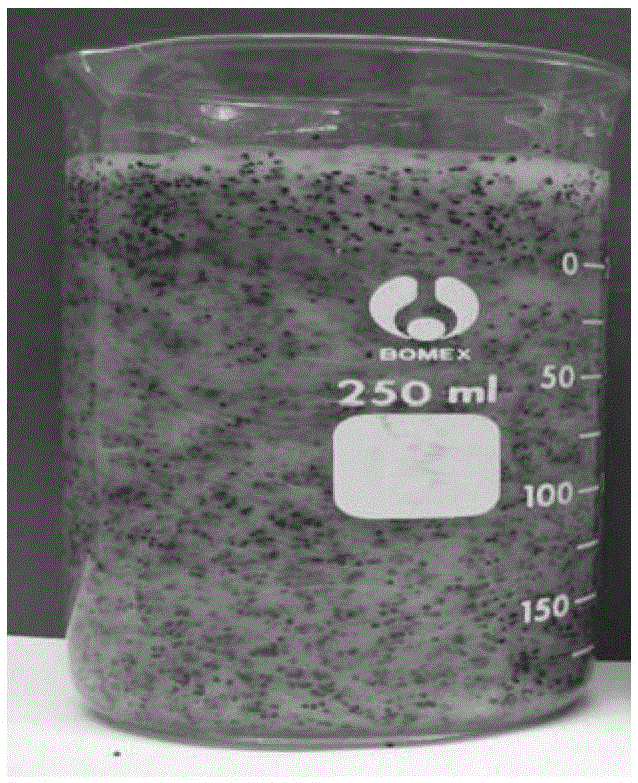

[0075](2) Preparation of low-damage fracturing fluid base fluid (fracturing fluid of the present invention)

[0076] Measure 2000ml of tap water, add 1g of polyacrylamide (molecular weight: 8 million, Daqing Petrochemical) and 40g of potassium chloride successively under stirring conditions, and stir until completely dissolved.

[0077] (3) Proppant permeability test

[0078] According to the oil and gas industry standard SY / T6302-2009 "Recommended method for evaluation of short-term conductivity of fra...

Embodiment 2

[0087] Embodiment 2: gas well test

[0088] In order to reduce the damage of the fracturing fluid to the gas layer and the proppant zone, the low damage fracturing method of the present invention is used in the gas well. The overall plan is: use 0.08% by weight of low-concentration guar gum to hydraulically open formation fractures, then use 0.08% of low-concentration guar gum + 0.35% by weight of fiber as a sand-carrying fluid, and carry proppant with different sand ratios to fill In the fractures opened, the displacement fluid is finally used to replace the sand-carrying fluid into the formation.

[0089] The specific fracturing methods are:

[0090] 1. Fracturing string

[0091] The Φ73mm outer thickened combined tubing injection method is used for construction, and the tubing is lowered to a depth of 1550m.

[0092] 2. Fracturing process

[0093] ① Use 350 cubic meters of pre-fluid and inject it into the formation opening at a displacement of 6.0 to 6.5 cubic meters pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com