Systems and methods for improving energy efficiency in cooling plant compressors

A technology for cooling equipment in compressors, applied in emergency protection circuit devices for limiting overcurrent/overvoltage, refrigerators, refrigeration and liquefaction, etc., can solve problems such as inability to increase the efficiency of frequency inverters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

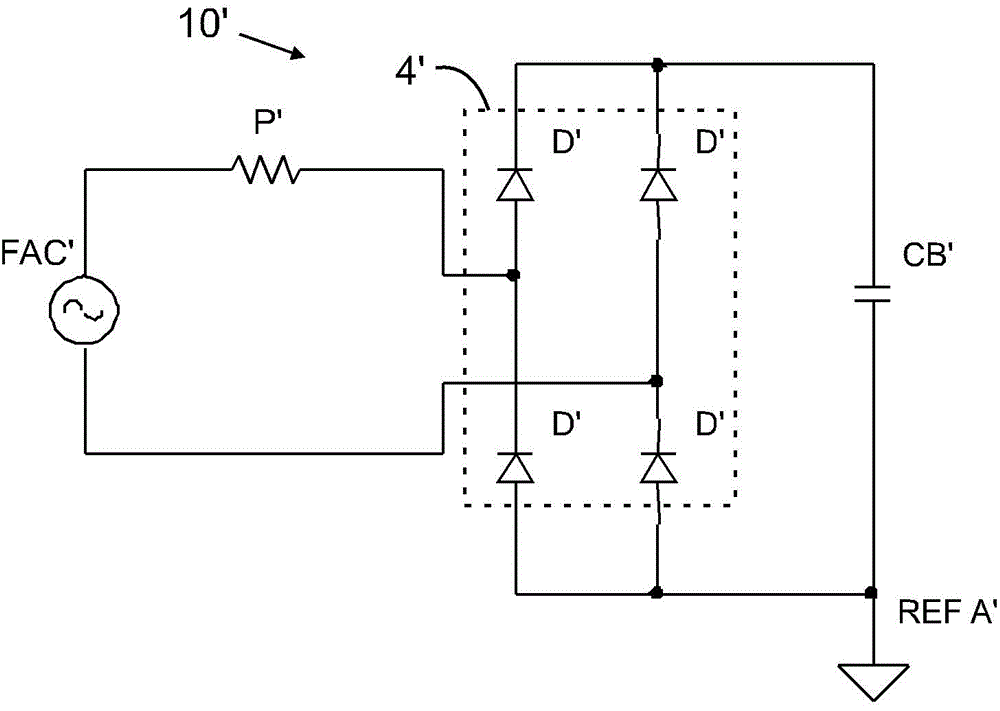

[0034] exist figure 2 and 3 A system for increasing energy efficiency in a compressor of a cooling plant according to the first and second preferred embodiments of the present invention is schematically shown in , respectively. The system has at least a frequency inverter with a main circuit 10 and an electrical energy source FAC electrically associated with each other. Preferably, the compressor is constituted by a variable capacity compressor, but other types of compressors may be used.

[0035] as in figure 2 and 3 As can be seen in , the main circuit 10 of the frequency inverter includes at least a wave rectifier 4 .

[0036] In addition, the main circuit 10 of the frequency inverter also comprises at least a bus capacitor CB electrically connected in parallel to the wave rectifier 4 , capable of being charged by a charging current.

[0037] In addition, the main circuit 10 of the frequency inverter comprises at least a passive part P electrically associated to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com