Solid super acid and method for catalyzing and preparing chloracetate by using same

A technology of solid superacid and chloroacetic acid, which is applied in the field of pesticide chemical industry, can solve the problems of difficult recycling and high cost, etc., and achieve the effect of low toxicity and harmless products, good stability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

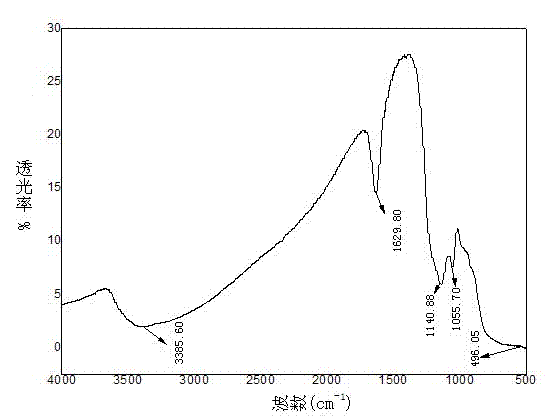

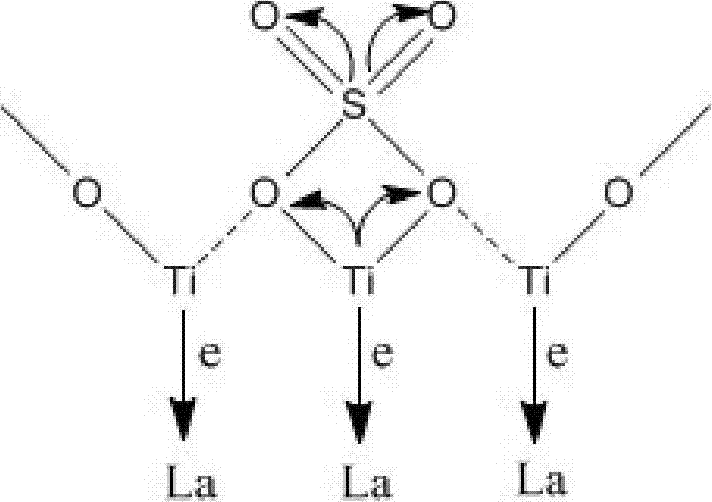

Method used

Image

Examples

Embodiment 1

[0027] Add 60 mL of absolute ethanol to the three-neck flask, add 30 mL of tetrabutyl titanate dropwise under vigorous stirring at about 25 ° C, and continue stirring for 30 min to obtain a uniform and transparent light yellow solution A; add 12 mL of glacial acetic acid and 20 mL of distilled water into 40mL of absolute ethanol and stirred for 30min to obtain solution B. Under vigorous stirring, add solution B dropwise to solution A at a rate of 1-2 drops / second. After dropping, continue stirring for 1 hour to obtain uniform and transparent light yellow TiO 2 Sol. The gel was dried at 80°C for about 10 h, and ground into xerogel powder. The powder was calcined at 325°C for 2h and cooled naturally to room temperature to prepare TiO 2 powder. 6.0g of La 2 o 3 Dissolved in 1.85mol / L dilute sulfuric acid solution to make 0.07mol / L La 3+ solution, and then TiO 2 Soak the powder in it for 14 hours, then filter it with suction, dry it by infrared, activate it at 450℃~500℃ for...

Embodiment 2

[0031] Add 80 mL of absolute ethanol to a three-neck flask, add 30 mL of tetrabutyl titanate dropwise under vigorous stirring at about 25°C, and continue stirring for 30 minutes to obtain a uniform and transparent light yellow solution A; add 23 mL of glacial acetic acid and 27 mL of distilled water into 50mL of absolute ethanol and stirred for 30min to obtain solution B. Under vigorous stirring, add solution B dropwise to solution A at a rate of 1-2 drops / second. After dropping, continue stirring for 1 hour to obtain uniform and transparent light yellow TiO 2 Sol. The gel was dried at 80°C for about 10 h, and ground into xerogel powder. The powder was calcined at 325°C for 2h and cooled naturally to room temperature to prepare TiO 2 powder. 6.0g of La 2 o 3 Dissolved in 1.85mol / L dilute sulfuric acid solution to make 0.07mol / L La 3+ solution, and then TiO 2 Soak the powder in it for 14 hours, then filter it with suction, dry it by infrared, activate it at 450℃~500℃ for...

Embodiment 3

[0035]Add 70mL of absolute ethanol to the three-neck flask, add 30mL of tetrabutyl titanate dropwise under vigorous stirring at about 25°C, and continue stirring for 30min to obtain a uniform and transparent light yellow solution A; add 18mL of glacial acetic acid and 25mL of distilled water into 50mL of absolute ethanol and stirred for 30min to obtain solution B. Under vigorous stirring, add solution B dropwise to solution A at a rate of 1-2 drops / second. After dropping, continue stirring for 1 hour to obtain uniform and transparent light yellow TiO 2 Sol. The gel was dried at 80°C for about 10 h, and ground into xerogel powder. The powder was calcined at 325°C for 2h and cooled naturally to room temperature to prepare TiO 2 powder. 6.0g of La 2 o 3 Dissolved in 1.85mol / L dilute sulfuric acid solution to make 0.07mol / L La 3+ solution, and then TiO 2 Soak the powder in it for 14 hours, then filter it with suction, dry it by infrared, activate it at 450℃~500℃ for 3 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com