A kind of high-strength corrosion-resistant polypropylene composite material and its preparation method

A composite material and corrosion-resistant technology, which is applied in the field of high-strength corrosion-resistant polypropylene composite materials and its preparation, can solve the problems of not meeting actual needs and poor material performance, and achieve excellent mechanical properties, meet mechanical requirements, and corrosion resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

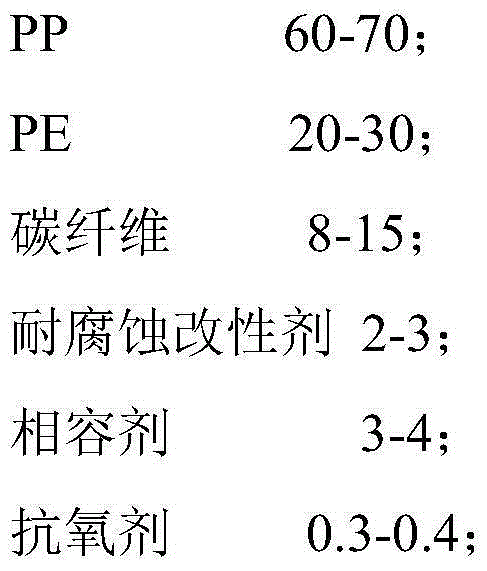

[0032] A kind of preparation method of high-strength corrosion-resistant polypropylene composite material, its raw material components and content are as shown in Table 1:

[0033] Table 1

[0034] raw material name

Example 1

Example 2

PP

79

61

PE

10

20

carbon fiber

8

15

Corrosion Modifier

0.5

0.5

Compatibilizer

3

4

168 / 1010(1∶1)

0.4

0.4

[0035] Wherein, the PP is a homopolypropylene resin with a melt index of 15-40g / 10min; PE is LLDPE; the carbon fiber is a chopped carbon fiber whose length is 4-7mm and whose tensile strength is >500kg / mm 2 , tensile modulus > 250G Pa; corrosion modifier is polytetrafluoroethylene; compatibilizer is maleic anhydride grafted polypropylene; antioxidant is hindered phenolic antioxidant and phosphite antioxidant agent compounding; the hindered phenolic antioxidant is antioxidant 1010, and the phosphite antioxidant is antioxidant ...

Embodiment 3

[0041] A preparation method of a high-strength corrosion-resistant polypropylene composite material, the method comprising the following steps:

[0042] (1) Weigh the raw materials according to the following components and parts by weight: PP30, PE40, carbon fiber 20, corrosion-resistant modifier 5, compatibilizer 10, antioxidant 0.5;

[0043] (3) Put the mixed raw materials of PP, PE, corrosion-resistant modifier, compatibilizer, and antioxidant into the screw machine, and the carbon fiber is metered in from the side feed, extruded and granulated, and the speed of the screw machine is controlled to be 180 -600rpm, the temperature is 190-220°C, the product is obtained by melt extrusion and granulation.

[0044] Wherein, the PP is a homopolypropylene resin with a melt index of 15-40g / 10min; PE is LLDPE; the carbon fiber is a chopped carbon fiber whose length is 4-7mm and whose tensile strength is >500kg / mm 2 , tensile modulus > 250G Pa; corrosion modifier is polytetrafluoroeth...

Embodiment 4

[0046] A preparation method of a high-strength corrosion-resistant polypropylene composite material, the method comprising the following steps:

[0047] (1) Weigh the raw materials according to the following components and parts by weight: PP70, PE10, carbon fiber 5, corrosion-resistant modifier 0.5, antioxidant 0.1;

[0048] (3) Put the mixed raw materials of PP, PE, corrosion-resistant modifier and antioxidant into the screw machine, and the carbon fiber is metered in from the side feeding, extruded and granulated, and the rotating speed of the screw machine is controlled to be 180-600rpm, and the temperature The temperature is 190-220°C, and the product can be obtained by melt extrusion and granulation.

[0049] Wherein, the PP is a homopolypropylene resin with a melt index of 15-40g / 10min; PE is LLDPE; the carbon fiber is a chopped carbon fiber whose length is 4-7mm and whose tensile strength is >500kg / mm 2 , tensile modulus > 250G Pa; corrosion resistance modifier is pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com