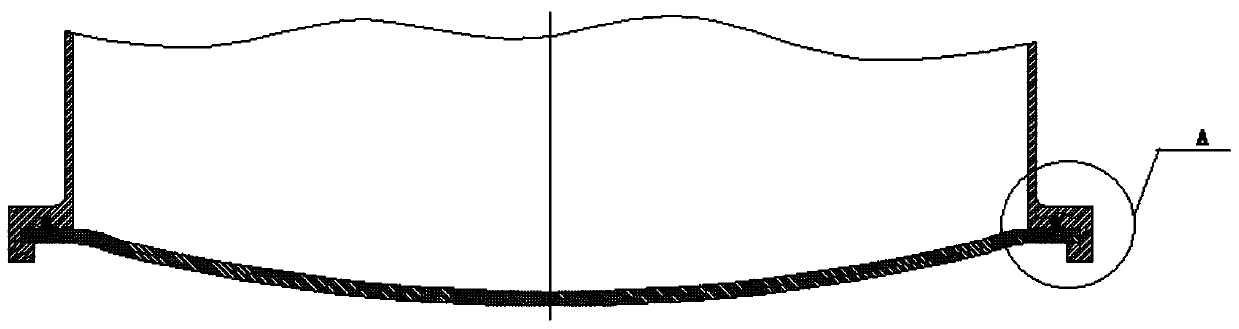

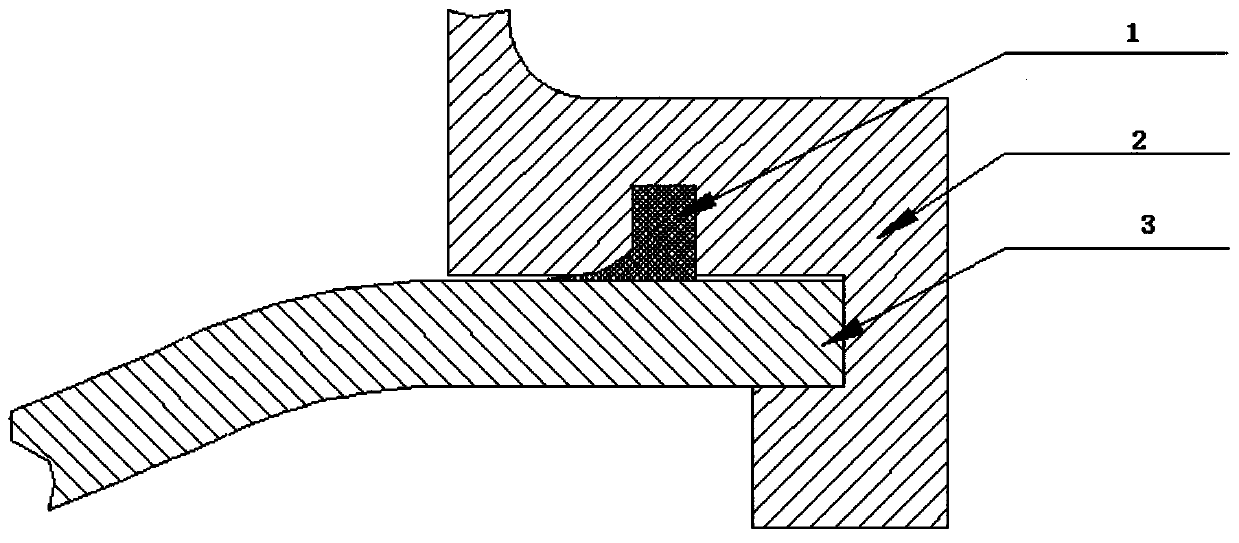

A high-temperature-resistant and aging-resistant EPDM rubber seal and preparation method thereof

A technology of EPDM rubber and seals, which is applied in the field of rubber materials, can solve problems such as greatly affecting production efficiency, failure of seals, hidden safety hazards, etc., and achieve good processing performance, good elasticity and processing fluidity, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

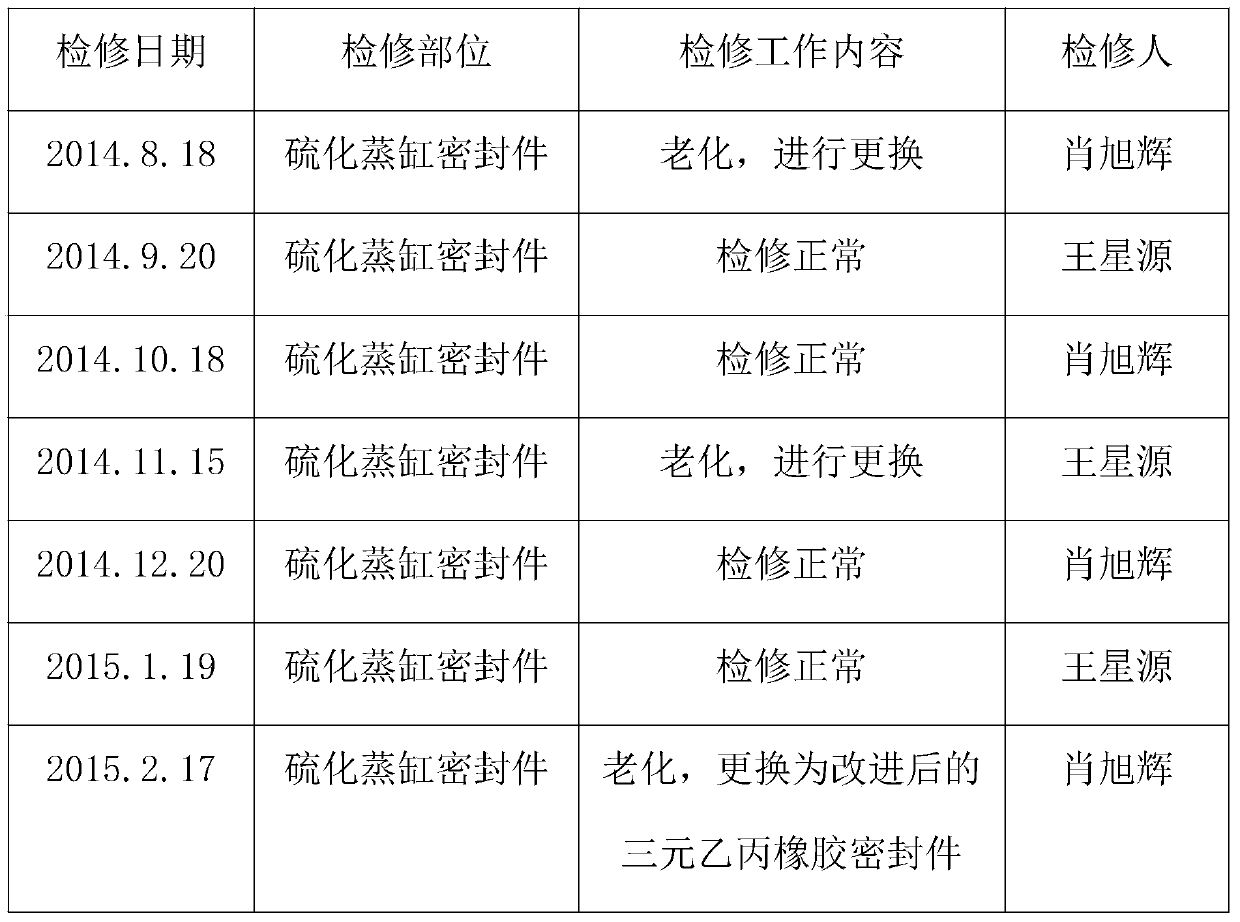

[0049] The preparation method of the aging-resistant EPDM sealing member for the above-mentioned high-temperature vulcanization steamer comprises the following steps: A, pre-smelting: 80-90 parts of EPDM rubber and 10-20 parts of saturated styrene thermoplastic elastomer The parts are combined in the open mill, thin pass 6-8 times, and the roll distance is 1mm. B. Mixing: Add filling reinforcing agent and plasticizer to the rubber obtained in step A, then add other components such as vulcanizing agent, accelerator, active agent, etc., and carry out mixing. The mixing time is 10-20min. The distance is 3-4mm, the temperature of the mill is controlled at 50-70°C, and the sheet is parked for 24 hours to obtain the mixed rubber. C. Re-milling: re-milling the mixed rubber obtained in step B, the number of times of thinning is 4-6 times, the roller distance is 1mm, the temperature of the open mill is 40-60°C, and then the sheet is produced, and the thickness of the sheet is 3-5mm. D...

Embodiment 1

[0054] An aging-resistant EPDM seal for high-temperature vulcanized steam cylinders, the EPDM seal includes the following components: 80 parts of EPDM, 20 parts of saturated styrene thermoplastic elastomer , 11 parts of active agent, 3.4 parts of vulcanizing agent, 2 parts of accelerator, 55 parts of filling and reinforcing agent, 5 parts of plasticizer, and 1 part of microcrystalline wax. Wherein, active agent selects 10 parts of metal oxides and 1 part of stearic acid for use; Vulcanizing agent selects 0.4 part of sulfur for use, 2 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane ( Double 2-5), 1 part of triallyl isocyanurate (TAIC); the accelerator uses 1 part of 4,4'-dithiodimorpholine (DTDM), 1 part of dipentylene cyridine tetrasulfide Mu (TRA); 50 parts of carbon black (including 5 parts of O carbon black) and 5 parts of silicate attapulgite modified clay are selected as filling reinforcing agent; 5 parts of paraffin oil are selected as plasticizer.

[0055] The p...

Embodiment 2

[0057] An aging-resistant EPDM seal for high-temperature vulcanized steam cylinders, the EPDM seal includes the following components: 90 parts of EPDM, 10 parts of saturated styrene thermoplastic elastomer , 17 parts of active agent, 5.8 parts of vulcanizing agent, 4 parts of accelerator, 70 parts of filling and reinforcing agent, 15 parts of plasticizer, and 2 parts of microcrystalline wax. Wherein, activator selects 15 parts of metal oxides and 2 parts of stearate; Vulcanizing agent selects 0.8 part of sulfur, 3 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (Double 2-5), 2 parts of triallyl isocyanurate (TAIC); 1 part of N-cyclohexyl-2-benzothiazole sulfenamide (CZ) as accelerator, 1 part of tetrasulfide Methylthiuram (TMTD), 1 part of 4,4'-dithiodimorpholine (DTDM), 1 part of dipentylthiuram tetrasulfide (TRA); 60 parts of carbon black ( It contains 20 parts of O carbon black) and 10 parts of silicate attapulgite modified clay; the plasticizer is selected from 10 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com