Treatment process of printing and dyeing wastewater and chemical wastewater and structures thereof

A technology for chemical wastewater, printing and dyeing wastewater, applied in the fields of environmental pollution and treatment, resource recovery and utilization, can solve the problems of high energy consumption, complex water quality components, and difficulty in popularizing wastewater treatment and reuse processes, and achieves low chromaticity, COD good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

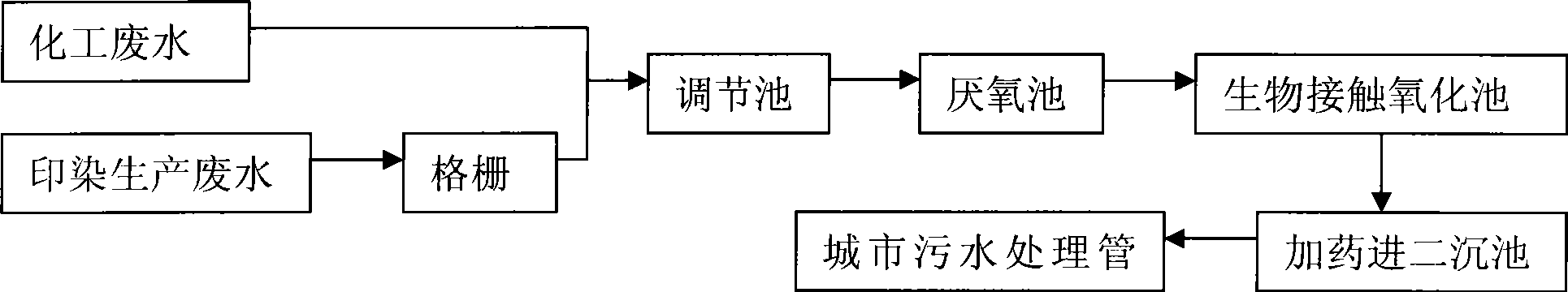

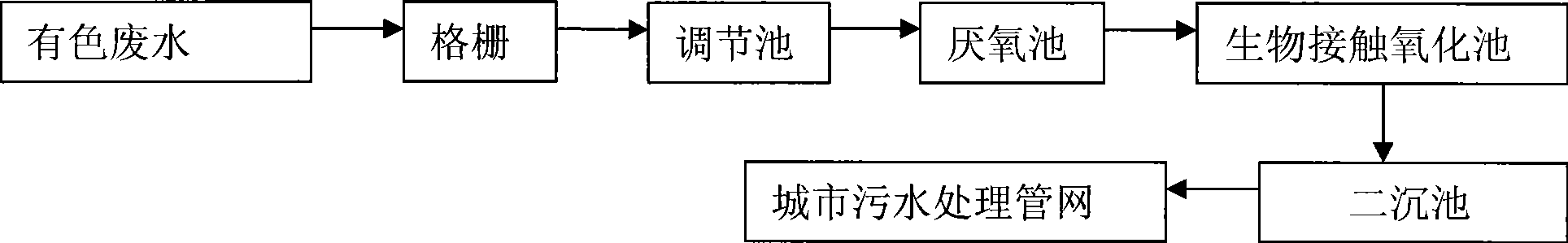

[0047] Such as Figure 7 A treatment process for printing and dyeing wastewater and chemical wastewater, which separates the wastewater into colorless and colored wastewater and treats them separately, respectively realizing the reuse of colorless wastewater after advanced treatment and the standard discharge of colored wastewater:

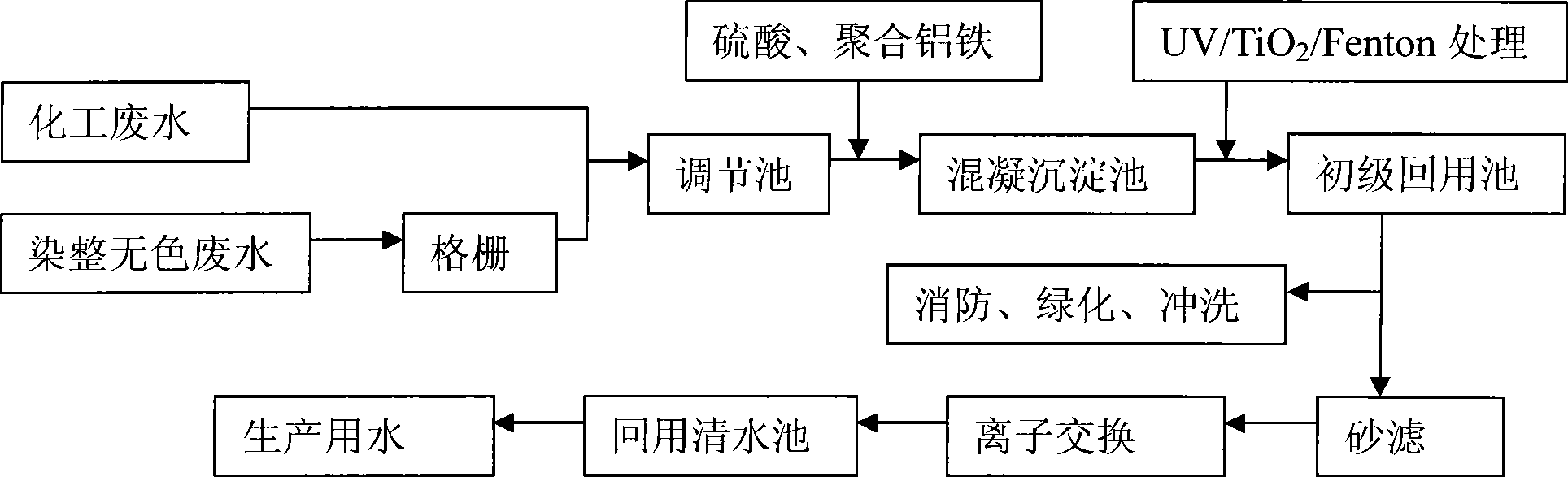

[0048] Such as figure 2 As shown, the colorless wastewater flows into the colorless regulating tank and then flows into the sedimentation tank. The coagulation agent is added to the water inlet of the sedimentation tank, and the strong acid coagulation process is adopted. The coagulant agent added at the entrance of the sedimentation tank is sulfuric acid and polyaluminum iron. , so that the pH value of sewage is controlled within the range of 1-2. The coagulated sediment is discharged from the bottom of the sedimentation tank into the sludge tank, and hydrogen peroxide and TiO are added to the outlet of the sedimentation tank 2 , to irradiate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com