Ballastless track system

A ballastless track and track slab technology, which is applied in the field of track systems, can solve the adverse effects of train stability and comfort on the durability of the track system, the longitudinal ends of the track slab are prone to warping, and poor environmental adaptability and maintainability and other problems, to achieve the effect of easy maintenance, convenient engineering quality and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

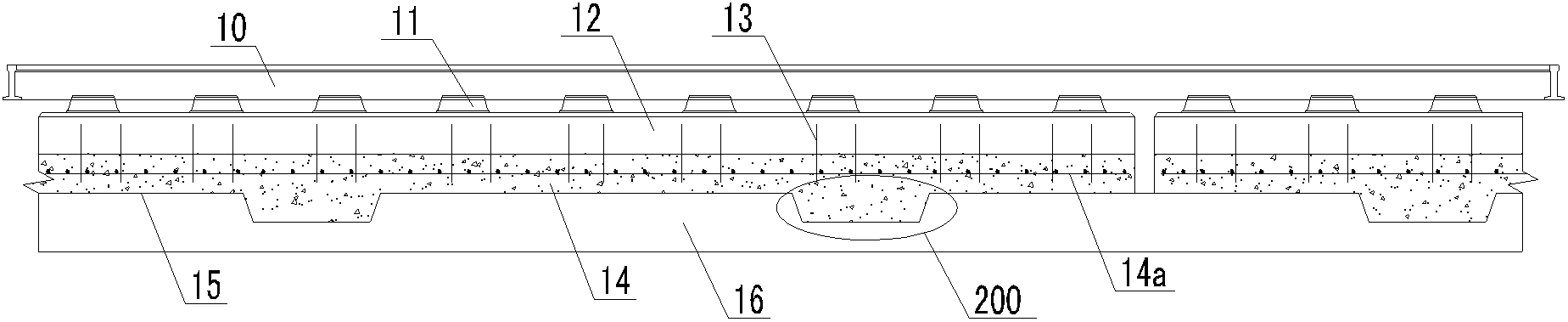

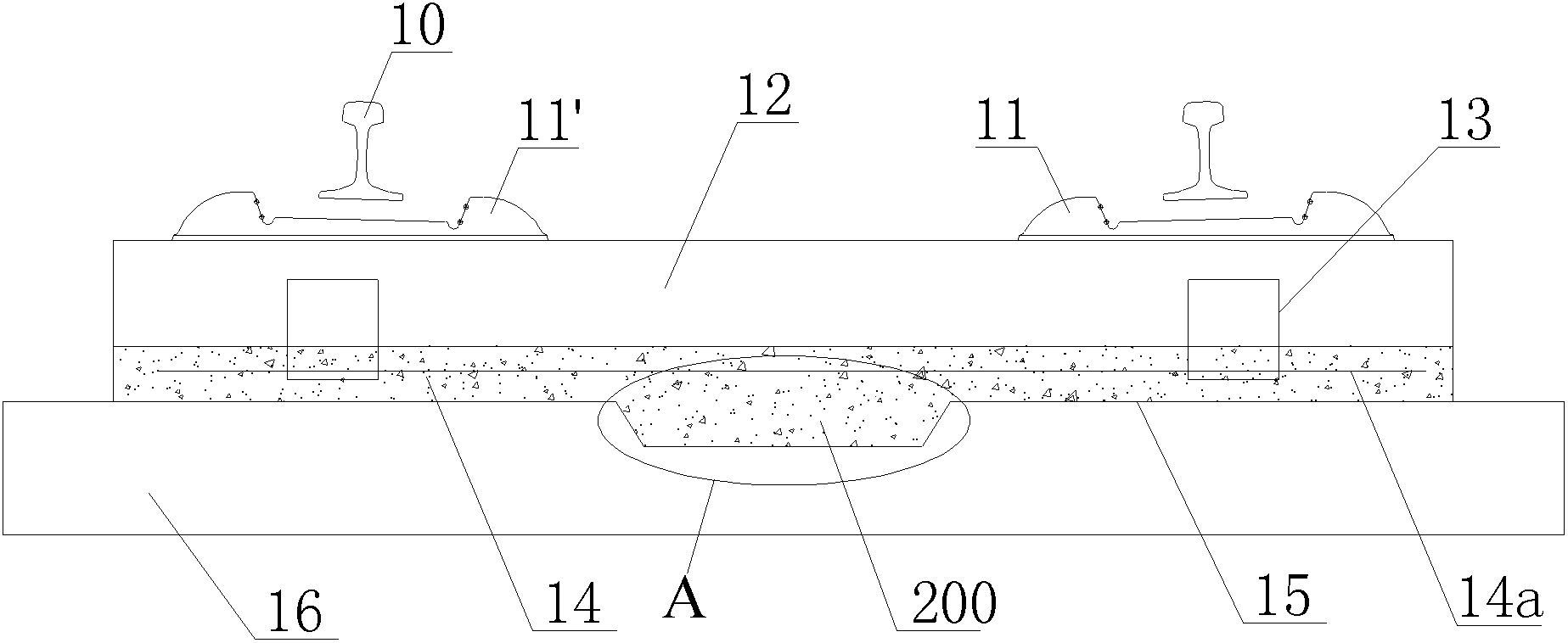

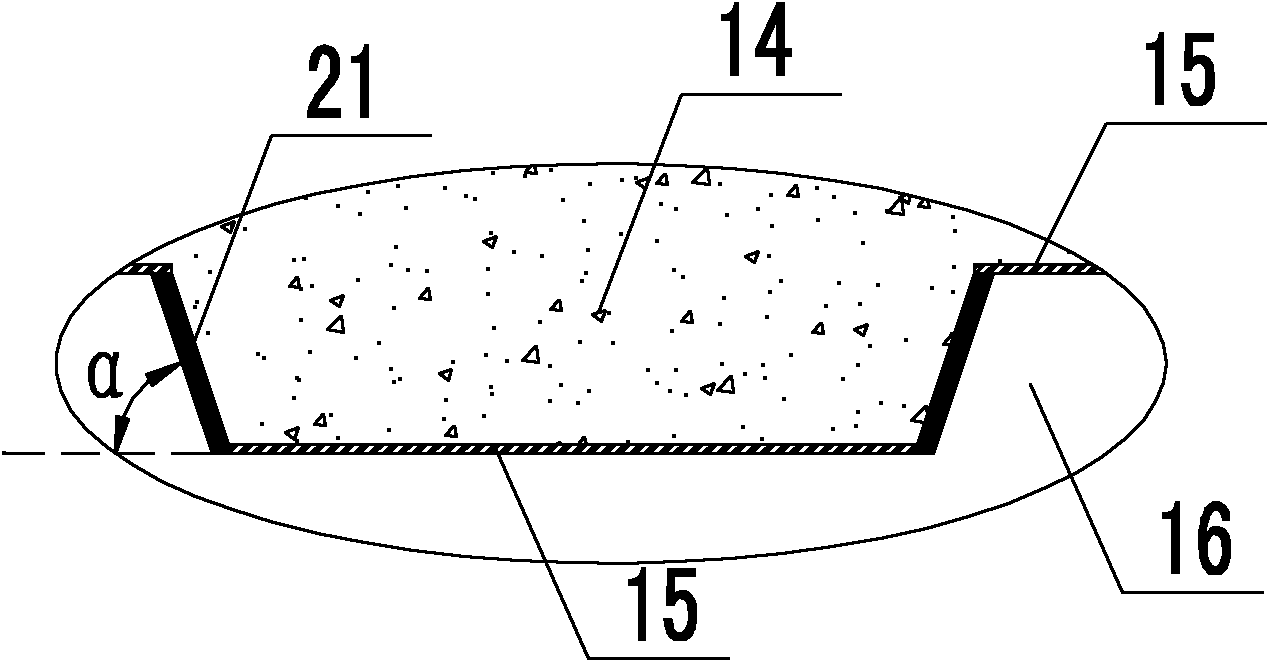

[0033] figure 1 It shows a schematic view of the longitudinal section structure of Embodiment 1 of the ballastless track system according to the present invention; figure 2 show figure 1 Schematic cross-sectional view of the ballastless track system. see in conjunction figure 1 and figure 2 , As can be seen from the figure, the ballastless track system of the present embodiment includes: base 16, track plate 12, pouring layer 14, connector 13, two columns of rail bearing platforms 11 and 11' and rail 10. In the above structure, the track slab 12 is arranged above the base 16; the pouring layer 13 is arranged between the base 16 and the track slab 12, the pouring layer 14 is formed by fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com