Prestressed concrete solid square pile and making method thereof

A concrete and prestressed technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of too many consumables, inability to place the pile tip, high cost, improve the comprehensive performance index, improve the ability to penetrate into the rock, The effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

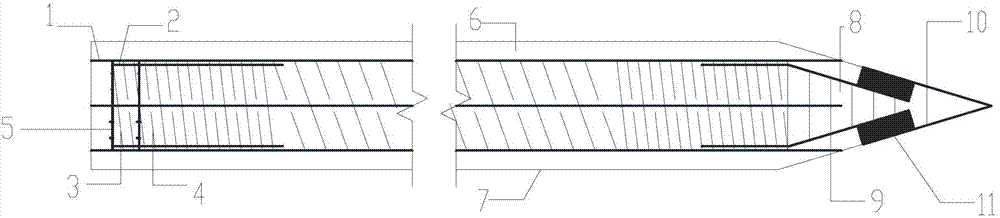

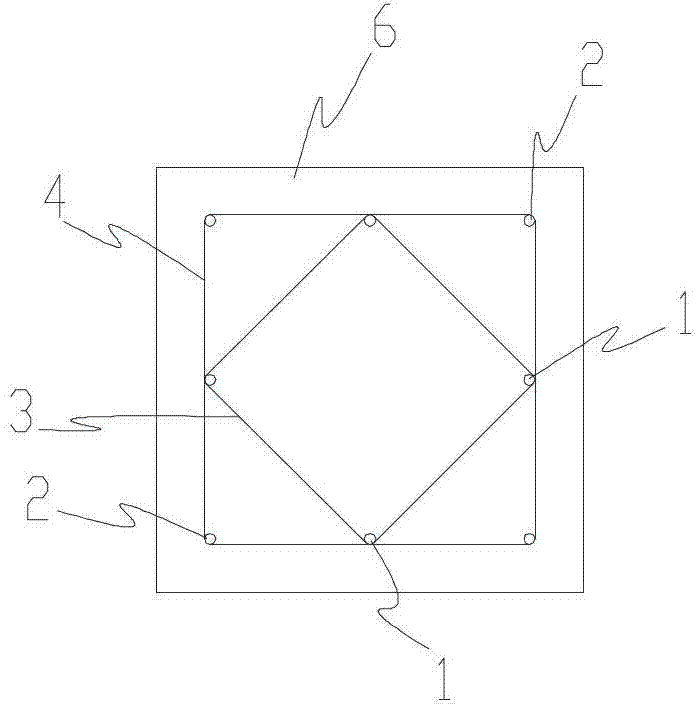

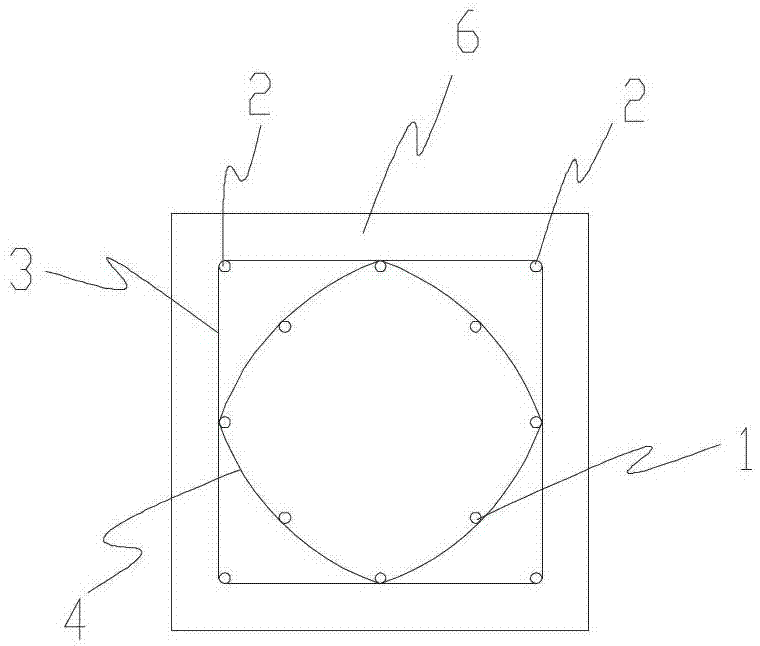

[0027] combine Figure 1 to Figure 5 , a prestressed concrete solid square pile, comprising a reinforcement cage, four non-prestressed additional main reinforcements, a pile point, a pile end mesh and concrete. The main reinforcement of the above-mentioned reinforcement cage adopts steel rods for prestressed concrete. It consists of two cages, the inner and the outer. The outer cage is formed by sliding and welding the stirrups in a spiral shape respectively. The above four non-prestressed additional main reinforcements are made of ordinary steel bars, which are respectively located at the four corners of the outer cage at the pile end; The whole is poured into a whole solid square pile.

[0028] Preferably, the outer cage is made of 4×m steel rods for prestressed concrete, which are spirally slid and welded through stirrups, forming a regular quadrilateral, m≧1. The above-mentioned inner cage body is formed by 4×n steel rods for prestressed concrete, which are spirally sli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com