MWT solar cell and method of making the same

The technology of a solar cell and its manufacturing method, which is applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency, achieve the effects of improving photoelectric conversion efficiency, increasing the light-receiving area, and reducing battery bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] As described in the background, the basic structure of an N-type solar cell in the prior art includes: a front electrode, an anti-reflection layer, a front surface field, an N-type substrate, a back emitter, a back field, and a back electrode. This conventional N-type The photoelectric conversion efficiency of solar cells is low.

[0045] The reason that causes above-mentioned shortcoming mainly contains three points: 1, the structure of the aluminum back emitter of N-type solar cell in the prior art makes the compound current of solar cell larger; 2, the front electrode of solar cell in the prior art includes main gate 3. In the prior art, the front surface field of the N-type solar cell covers the entire area of the front of the substrate, resulting in more carrier recombination on the front of the solar cell. .

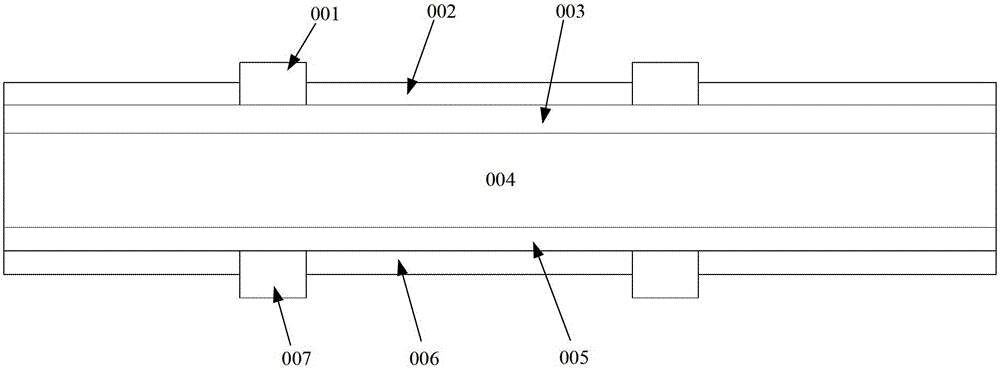

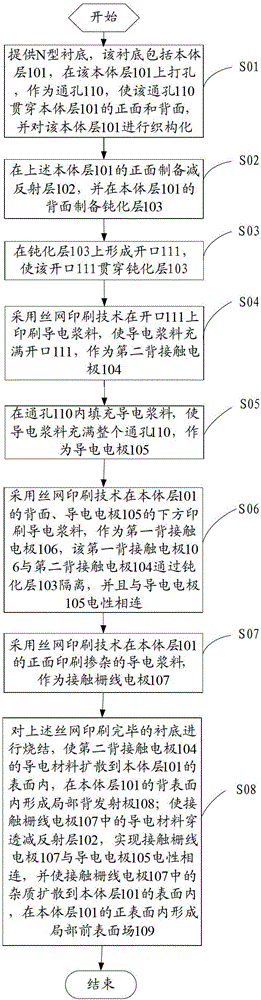

[0046] The conventional MWT solar cell is a Metal Wrap-Through solar cell, and its manufacturing process is: after the substrate is etched, textured, dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com