Three liquid vacuum cleaner

A vacuum cleaning machine and cleaning chamber technology, applied in the field of cleaning machines, can solve the problems of difficulty in using flammable solvents, differences in cleaning quality, and high viscosity of quenching oil, achieve better cleaning effect, reduce saturated vapor pressure, and simplify the operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

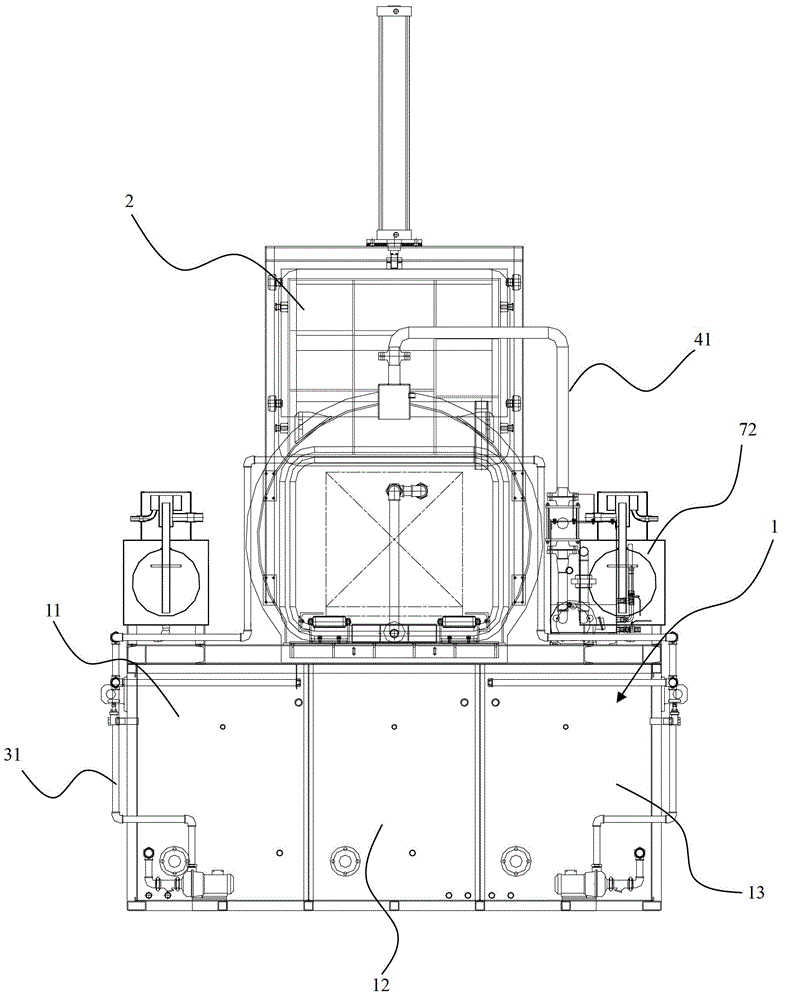

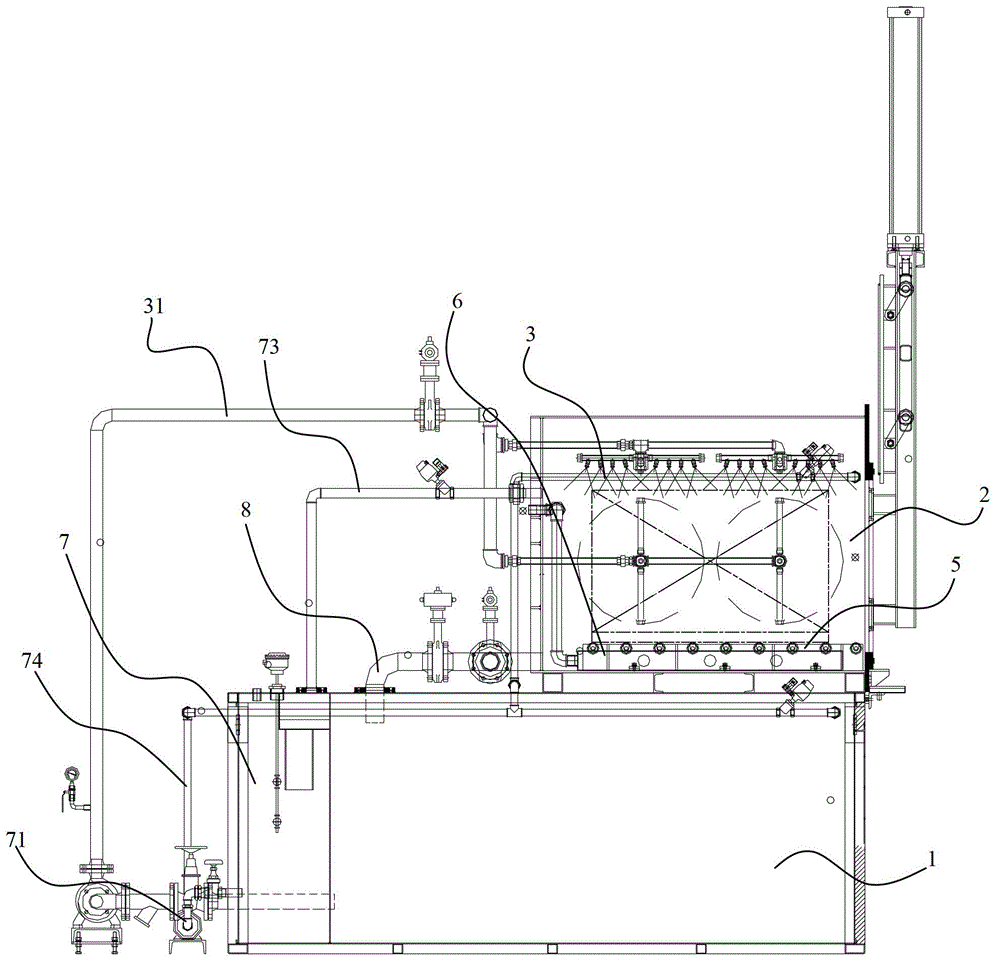

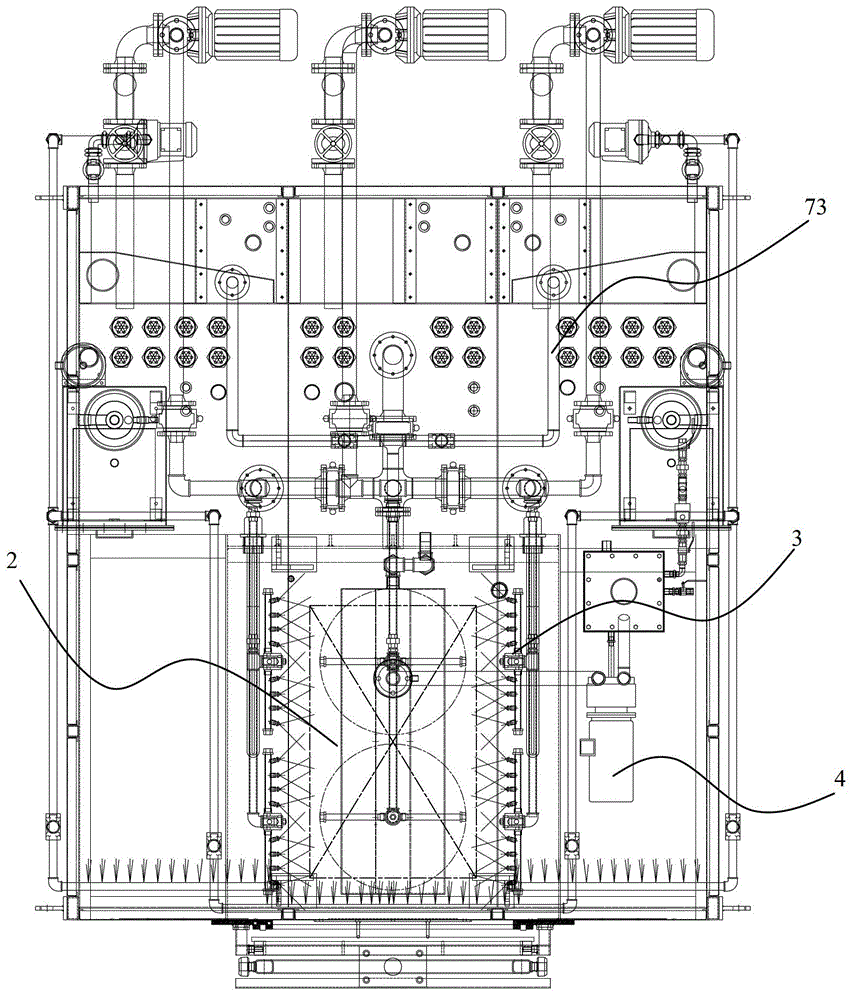

[0023] see figure 1 , figure 2 , image 3 , a kind of three-fluid vacuum cleaning machine of the present invention, comprises a general liquid tank 1, is arranged on a cleaning chamber 2 above the general liquid tank and a spray system 3 that is arranged on the inside of the cleaning chamber 2, and the cleaning chamber 2 is made of steel plate vacuum Sealed and welded, the spray system 3 communicates with the total liquid tank 1 through the spray pipe 31, and the return pipe 8 is connected between the cleaning chamber 2 and the total liquid tank 1; the nozzle of the spray system 3 adopts a rotating nozzle. Cleaning room 2 is provided with a room door and is provided with a material setting table 5 in cleaning room 2, and total liquid tank 1 is divided into a low-concentration cleaning liquid tank, a clean water tank and a high-concentration cleaning liquid tank, low-concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com