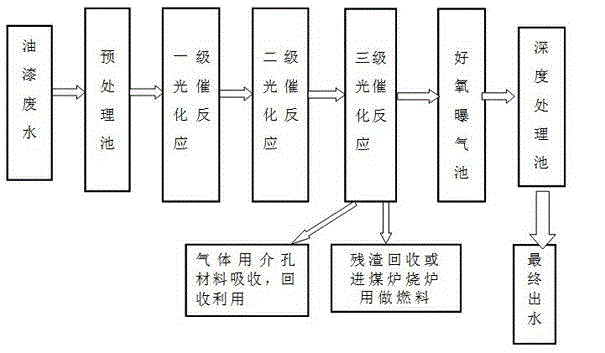

Multistage photocatalytic treatment process for paint wastewater with ultraviolet visible light

A treatment process, photocatalytic technology, applied in water/sewage multi-stage treatment, energy wastewater treatment, water/sludge/sewage treatment, etc., to achieve obvious energy-saving effect, simple operation and less process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] COD Cr About 240000mg / L, NH 3 -N is about 2200mg / L of high-concentration paint wastewater into the pretreatment pool, after rough treatment, adjust the pH=7.5, and add photocatalytic materials, introduce multi-stage photocatalytic equipment, after multiple cycles of reaction, the water COD Cr About 6400mg / L, NH 3 -N is about 500mg / L, the effluent is introduced into the bioremediation tank, aerobic sludge is added to it according to the mass ratio of sludge to water at 1:50, and intermittent aeration is performed, the COD of the water body after seven days Cr About 1400mg / L, NH 3 -N is about 50mg / L, and then chlorine dioxide is added to the water body at a ratio of 1:5000 by mass ratio of chlorine dioxide to water, and the COD of the final effluent Cr 95mg / L, NH 3 -N is 30mg / L, pH=7.1, chroma is less than 50. It has reached the secondary discharge standard of petrochemical industry in the "Integrated Wastewater Discharge Standard" (GB8978-1996).

specific Embodiment 2

[0027] COD Cr About 390000mg / L, NH 3 -N is about 1400mg / L of high-concentration paint wastewater into the pretreatment pool, after rough treatment, adjust the pH=8.0 and add photocatalytic materials, introduce multi-stage photocatalytic equipment, after multiple cycles of reaction, the water COD Cr About 10489mg / L, NH 3-N is about 440mg / L, the effluent is introduced into the bioremediation tank, and activated sludge is added to it according to the mass ratio of sludge to water at a ratio of 1:40, and intermittent aeration, the COD of the water body after seven days Cr About 2700mg / L, NH 3 -N is about 40mg / L, and then chlorine dioxide is added to the water body at a ratio of 1:2000 by mass ratio of chlorine dioxide to water, and the COD of the final effluent Cr 140mg / L, NH 3 -N is 30mg / L, pH=6.7, chroma is less than 50. It has reached the secondary discharge standard of petrochemical industry in the "Integrated Wastewater Discharge Standard" (GB8978-1996).

specific Embodiment 3

[0028] COD Cr About 310000mg / L, NH 3 -The high-concentration paint wastewater with N of about 1200mg / L is sent to the pretreatment tank, and after rough treatment, the pH is adjusted to 7.7. It can be discharged or recycled, and after adding photocatalytic materials, it is introduced into multi-stage photocatalytic equipment, and the water COD is produced after multiple cycles of reaction Cr About 8000mg / L, NH 3 -N is about 400mg / L, the effluent is introduced into the bioremediation tank, and activated sludge is added to it according to the mass ratio of sludge to water at a ratio of 1:50, and intermittent aeration, the COD of the water body after seven days Cr About 1700mg / L, NH 3 -N is about 35mg / L, and then chlorine dioxide is added to the water body at a ratio of 1:3000 by mass ratio of chlorine dioxide to water, and the COD of the final effluent Cr 125mg / L, NH 3 -N is 30mg / L, pH=6.9, chromaticity is less than 50, reaching the second-level discharge standard for petro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com