Polyurethane crackle paint for glass coating, and preparation method and applying method thereof

A polyurethane and crack paint technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems affecting application, poor transparency, poor adhesion, etc., achieve fast drying speed at room temperature, good adhesion strength and hardness, and excellent The effect of decoration and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

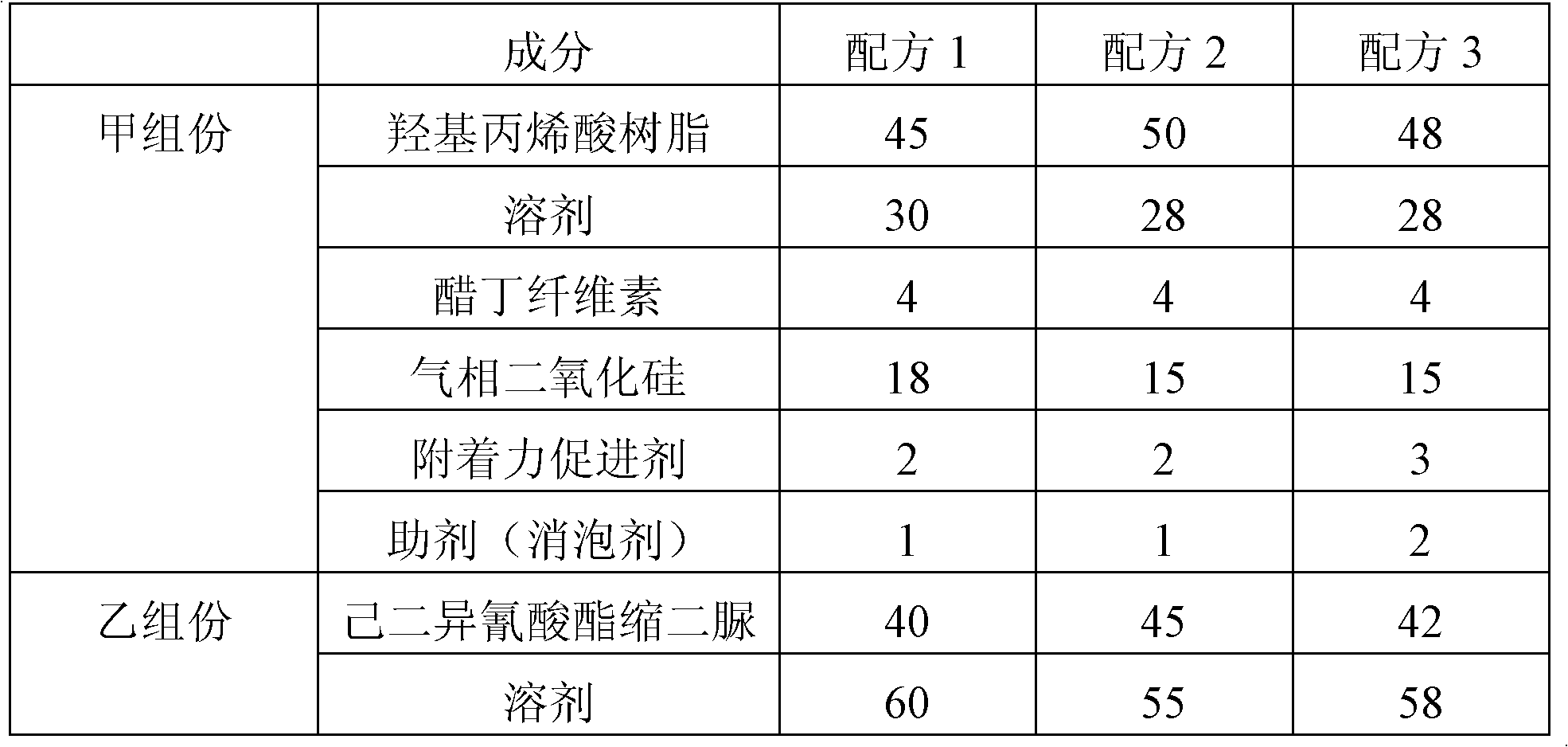

[0047] Recipe 1

[0048] Hydroxy-containing component A formula: (weight)

[0049] Hydroxy acrylic resin 45%,

[0050] Solvent 30%,

[0051] Acetyl cellulose 4%,

[0052] Fumed silica 18%,

[0053] Adhesion Promoter 2%,

[0054] Auxiliary (defoamer) 1%,

[0055] Curing agent component B formula: (weight)

[0056] Hexyl diisocyanate biuret 40%,

[0057] Solvent 60%.

[0058] For the rest, see Table 1 for the formula.

[0059] Table 1 each formula Kg of the present invention

[0060]

[0061] The hydroxy acrylic resin in the first component can be A450 from Bayer.

[0062] The solvent can be butyl acetate of Taixing Jinjiang urethane grade.

[0063] Cellulose acetate butyrate refers to cellulose acetate butyrate. The technical requirement is that the viscosity is 0.2 seconds. CAB551-0.2 from Eastman Company of the United States can be used.

[0064] Fumed silica can be A380 type fumed silica from German EVONIK company, technical requirements: specific surface area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com