Preparation method of aluminum based composite material having ultrahigh strength and controllable plasticity

An aluminum-based composite material and ultra-high-strength technology, which is applied in the field of preparation of aluminum-based composite materials, can solve the problems that high strength and large plasticity cannot coexist, and achieve the effect of low alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Firstly, the master alloy is prepared by electric arc furnace melting, and the composition is Al86; Ni6; Co2; Y4.5; La1.5 (at.%). Then the master alloy was remelted in a vacuum induction furnace, and an aluminum-based amorphous alloy sample with a diameter of 1 mm was prepared by copper mold casting. A 2 mm long sample was taken, both ends were ground flat, and put into a DSC device for isothermal annealing.

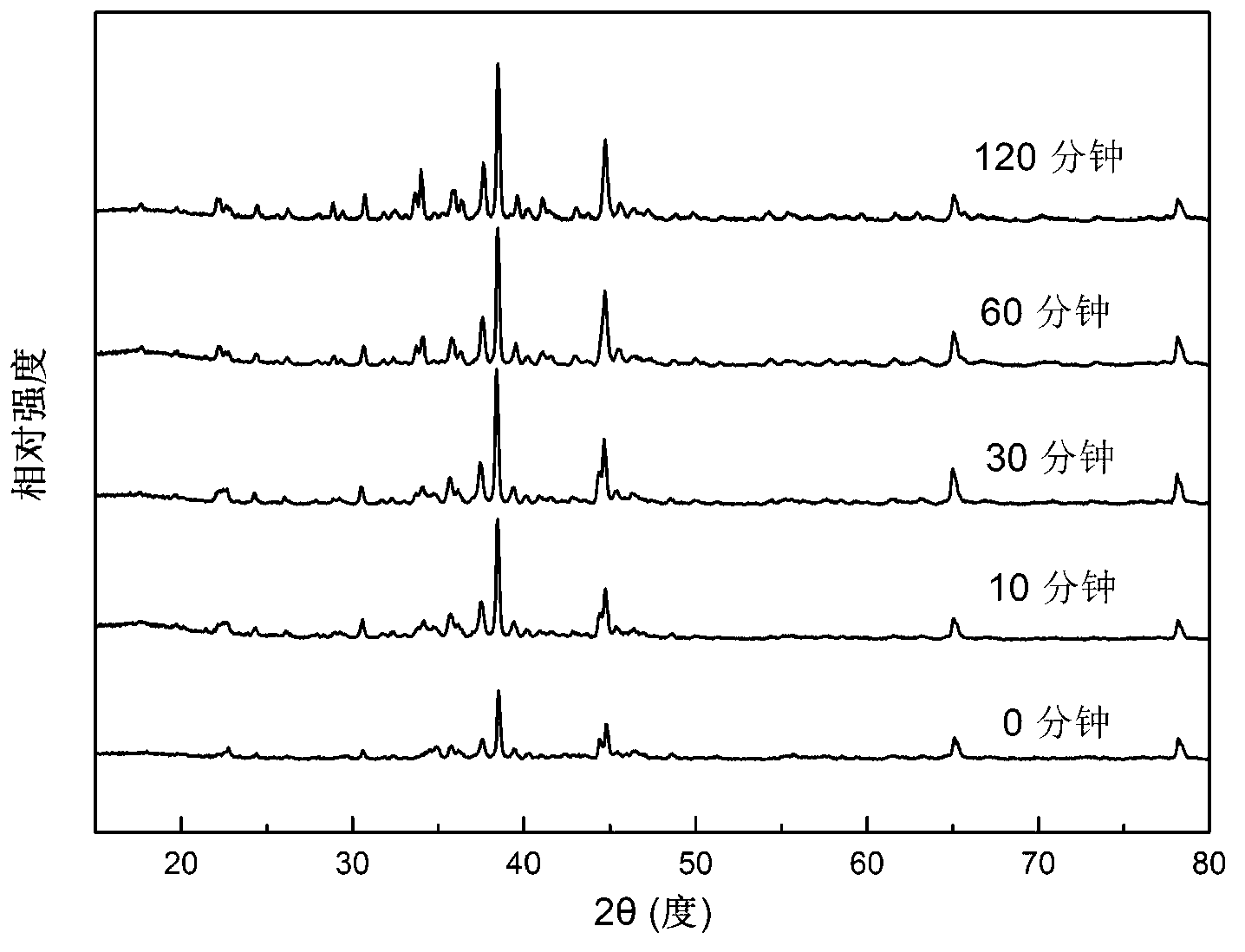

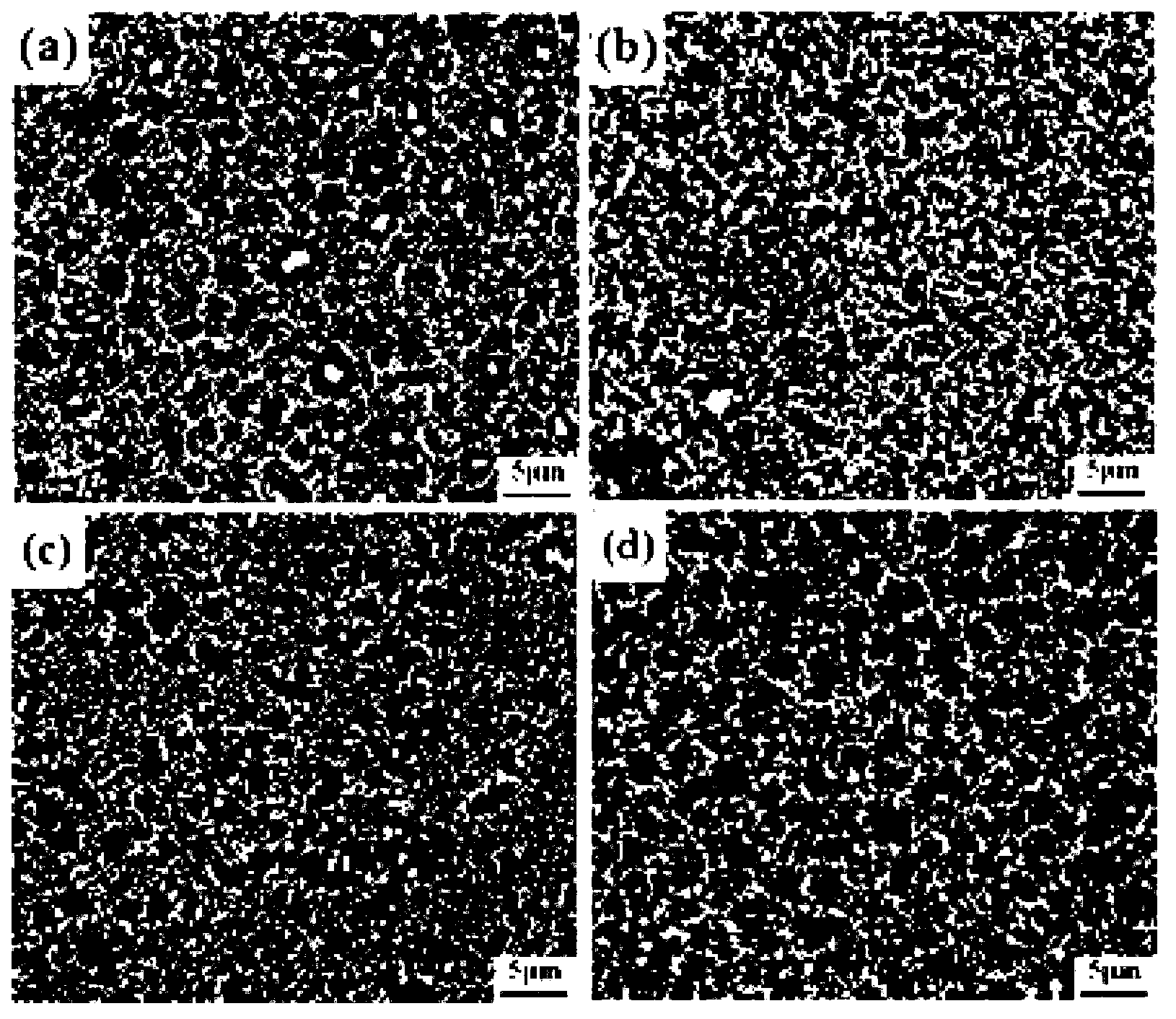

[0028] The specific process parameters are: the vacuum degree is not lower than 1.0×10 -5 mbar, the argon protection pressure is 100mbar, the casting temperature is 1100°C, the holding time is 70s, the injection pressure difference is 800mbar, the annealing temperature is 380°C, the annealing time is 60min, and the argon atmosphere. The X-ray diffraction pattern of the alloy is shown in figure 1 . image 3 Middle C is the SEM photo of the aluminum matrix composite.

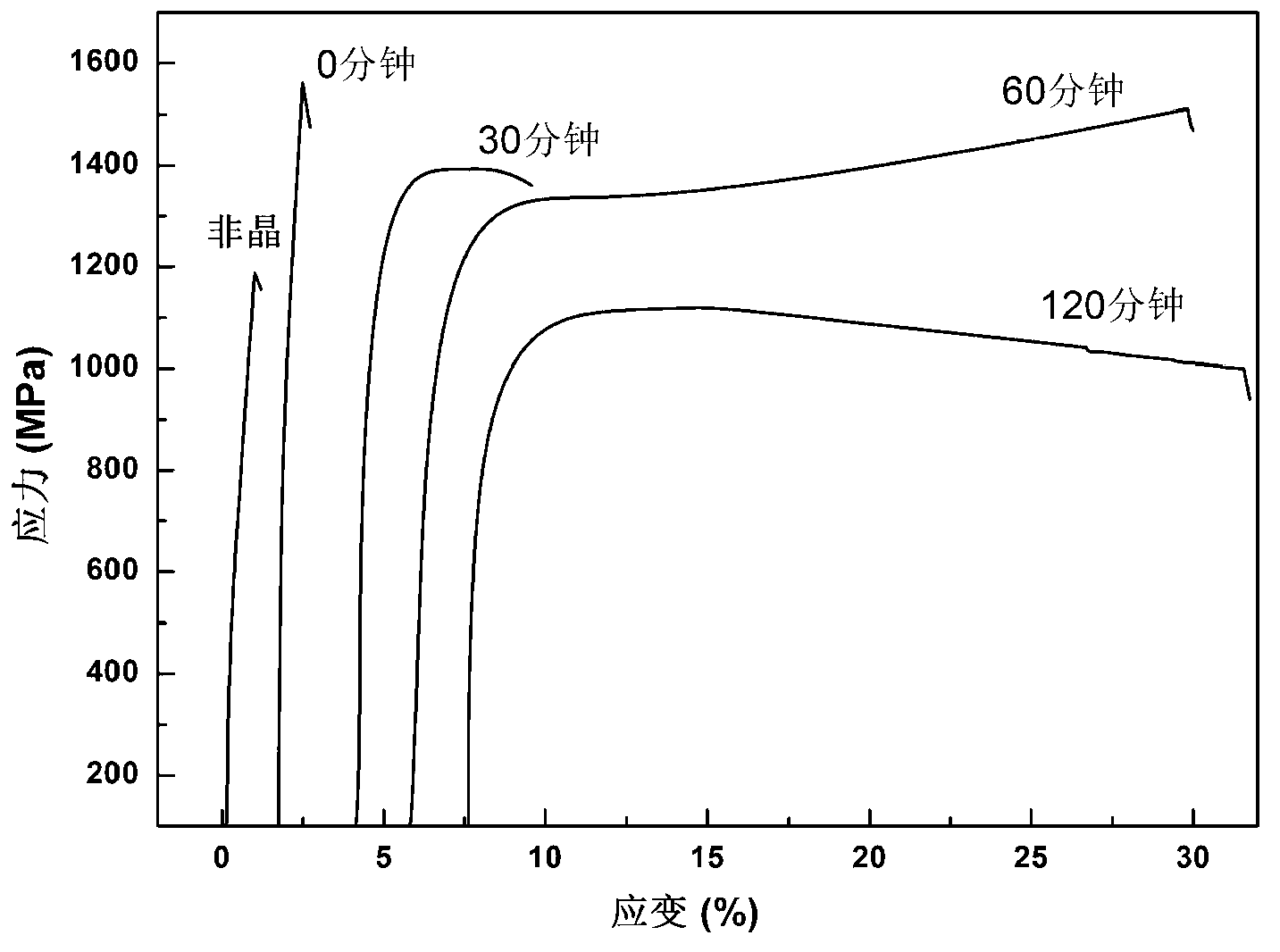

[0029] The room temperature compression performance test of the samples prepared in this experi...

Embodiment 2

[0031] The difference with Example 1 is:

[0032] The DSC annealing time used is different, which is 120min. The compression curve under this process is as follows figure 2 As shown, its organization is image 3 As shown in (d), Figure 5 (d) shows that the fracture mode of the alloy is splitting.

[0033] Result: Reduced compressive strength, no work hardening.

Embodiment 3

[0035] The difference with Example 1 is:

[0036] The annealing time of the present embodiment is 30min, and the compression curve under this technology is as follows figure 2 As shown, the sample organization is image 3 As shown in (b), Figure 5 (b) shows that the fracture mode of the alloy is chipping.

[0037] Results: The crystal grains are smaller, the fracture strength is slightly higher than that of Example 1, and the plasticity is about 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com