Gas-state fuel cyclone integrated igniter

A gaseous fuel and swirler technology, applied in the directions of combustion ignition, incandescent ignition, combustion method, etc., can solve the problems of affecting the effective length of ignition, increasing the manufacturing cost and design difficulty, and decreasing the success rate of ignition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

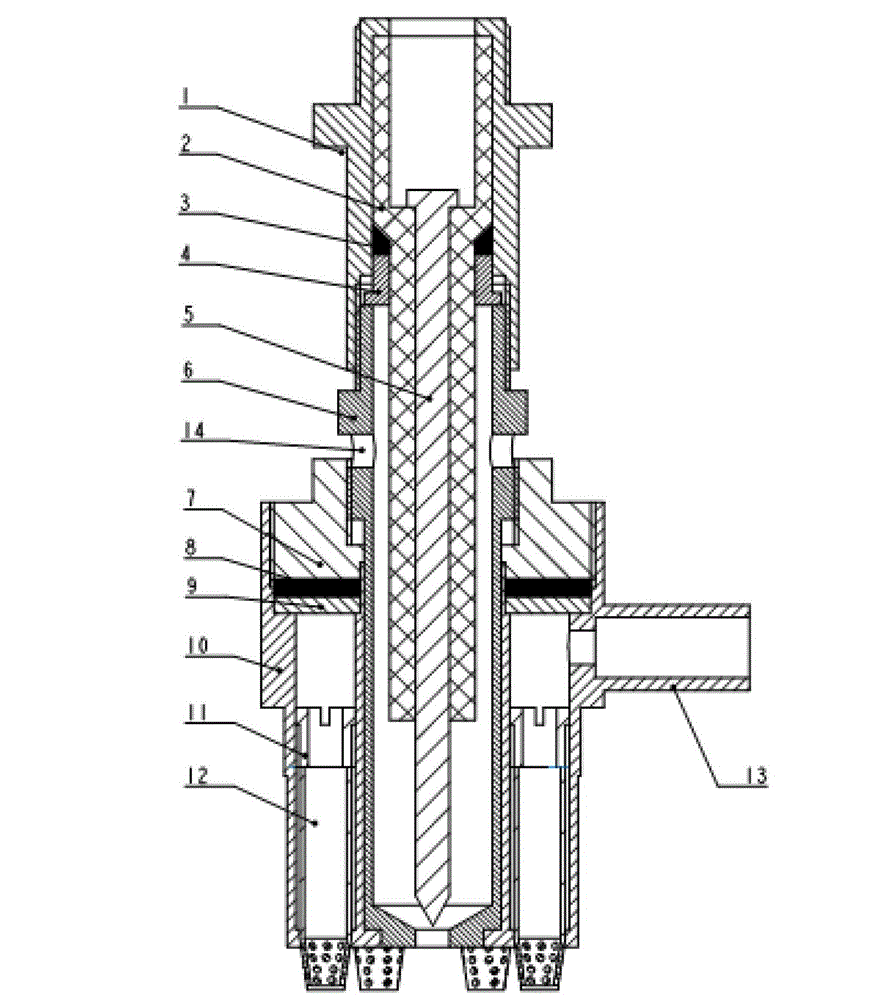

[0017] The gaseous fuel swirling integrated igniter of the present invention consists of a power connector 1, a ground electrode 6, a ceramic insulating medium 2, an inner electrode 5, a compression cover 7, a gasket 8, a compression ring 9, a gaseous fuel inlet 13, The gas fuel swirler 12, the fixed hollow nut 11, and the casing 10 of the swirler assembly are composed.

[0018] The plasma igniter is composed of the inner electrode 5 located in the center, the ground electrode 6 located outside the inner electrode, the ceramic insulating medium 2 between the inner electrode and the ground electrode, and the power connector 1 . A supporting ring is arranged between the ground electrode and the ceramic insulating medium, a certain gap is formed between the ground electrode and the ceramic insulating medium, and a graphite sealing ring 3 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com