Method for accelerating color printing iron corrosion by using electrochemical cathodic polarization

A cathodic polarization and electrochemical technology, applied in weather resistance/light resistance/corrosion resistance, scientific instruments, measuring devices, etc., can solve the problems of resolution and judgment scale difference, misjudgment, low resolution, etc., to improve the processing technology , optimized processing technology, and high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

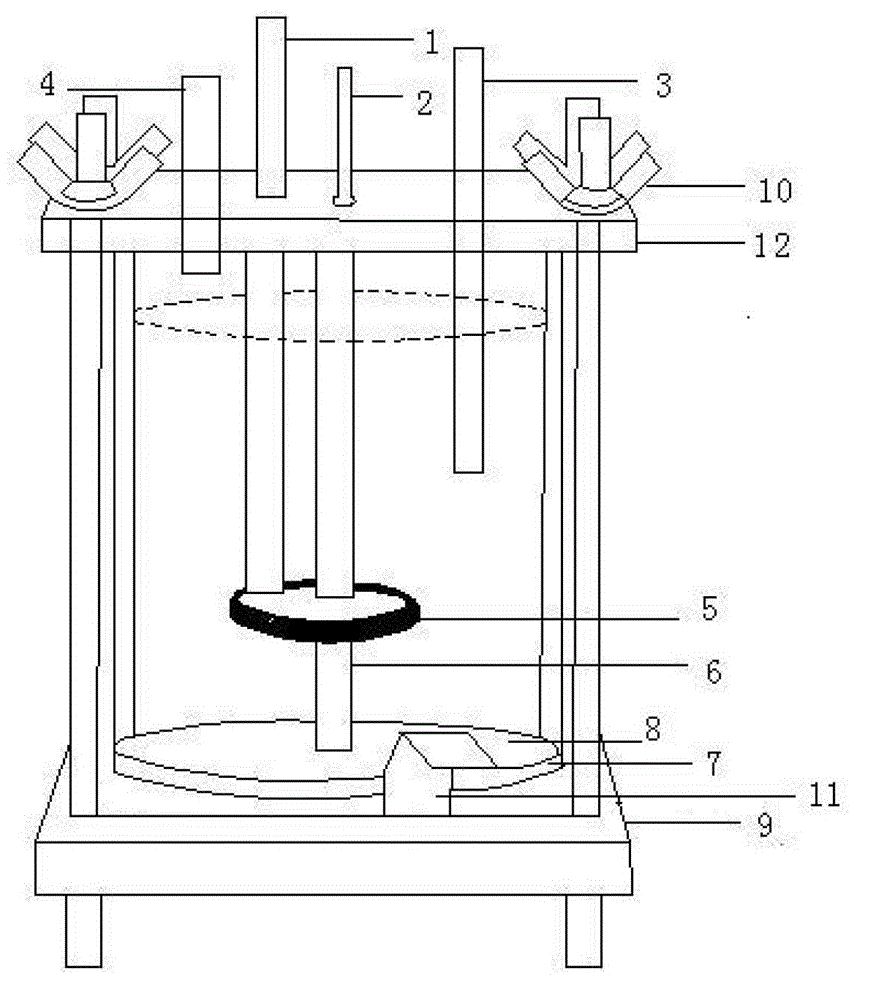

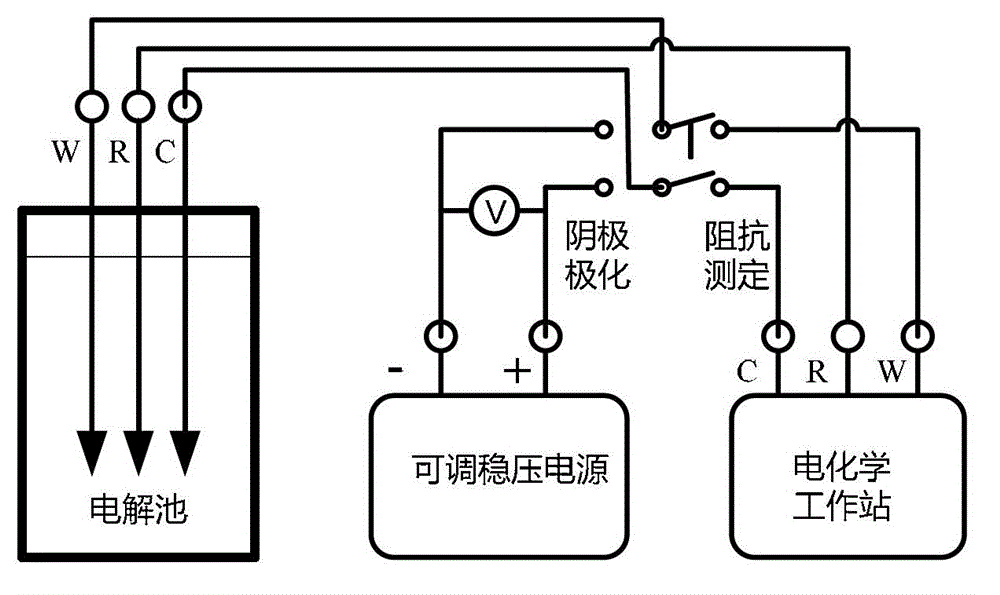

[0033] 1. Preparation of the instrument

[0034] Regarding the electrodes and electrolytic cells used in the present invention, the applicant’s prior application CN201210172244.9, titled “An electrolytic cell for testing the corrosion resistance of packaging materials”, has a detailed description, and this case refers to its Incorporated as part of this application.

[0035] according to figure 1 Install the electrolytic cell and electrodes. The color-printed iron working electrode is placed on the bottom of the tube-packed electrolytic cell, the working surface is placed on the top, the rubber ring is sealed, the upper cover is installed, the 4 positioning bolts are tightened, the reference electrode and the auxiliary electrode are installed in a suitable position, and the intake hose is installed. And the exhaust hose, open the nitrogen valve, adjust the flow rate to 2 bubbles / second, and keep nitrogen deoxygenation. The lower end of the reference electrode is installed i...

Embodiment 2

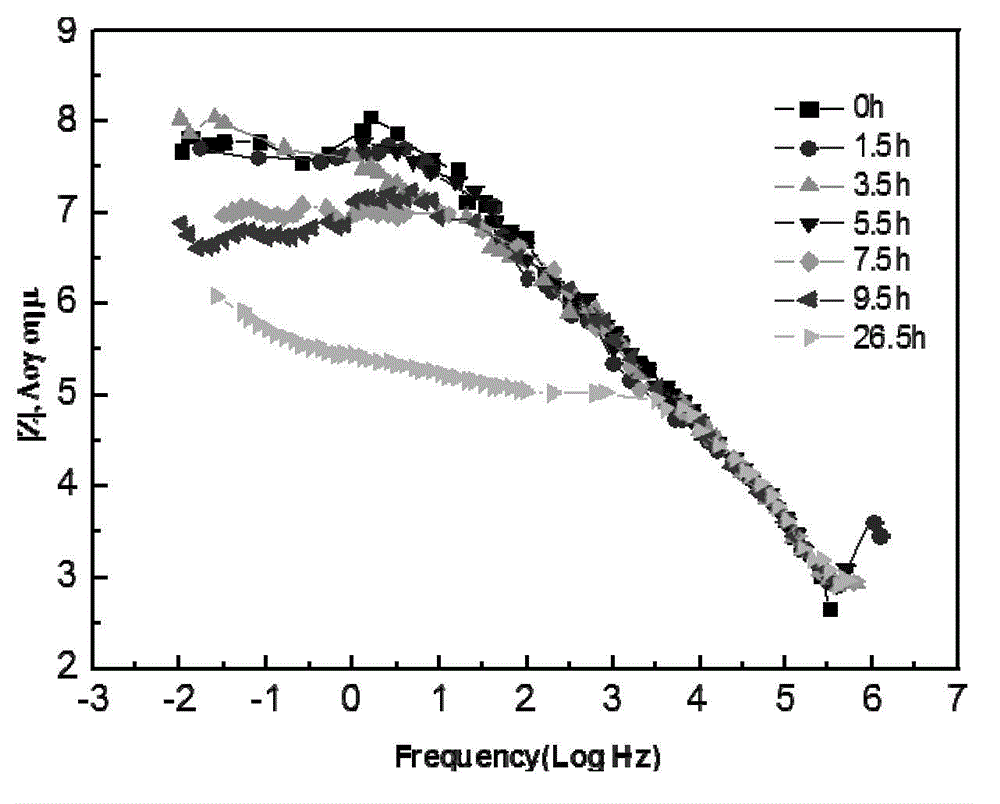

[0049] In addition to replacing -4.414V with the output voltage of the adjustable regulated power supply -6.414V, replacing 0h, 1.5h, 1.5h, Except for 3.5h, 5.5h, 7.5h, 9.5h, and 26.5h, the rest follow the same method as in Example 1.

[0050] Figure 4 It is the Bode diagram of the working electrode under the output voltage of the adjustable regulated power supply -6.414V. Depend on Figure 4 It can be seen that after 22.5 hours of cathodic polarization, the coating of the Red Bull beverage can has basically failed.

Embodiment 3

[0052] In addition to replacing -4.414V with the output voltage of the adjustable regulated power supply -7.414V, replacing 0h, 1.5h, 3.5h, 5.5 with electrochemical cathode polarization 0h, 1.5h, 3.5h, 5h, 9.5h, 22.5h Except h, 7.5h, 9.5h, and 26.5h, all the other follow the same method as in Example 1.

[0053] Figure 5(a)-Figure 5(b) It is the Bode diagram and the corrosion topography diagram of the working electrode under the output voltage of the adjustable regulated power supply -7.414V. Depend on Figure 5(a)-Figure 5(b) It can be seen that after 5 hours of cathodic polarization, the coating of the Red Bull beverage can has basically failed, and the corrosion spots are clearly visible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com