Epoxy resin insulating transformer

A technology for insulating transformers and epoxy resins, applied in plastic/resin/wax insulators, organic insulators, transformer/inductor coils/windings/connections, etc., can solve the problem of poor thermal conductivity of epoxy resins and affect the reliability of transformers , poor impact damage resistance, etc., to achieve the effect of increasing heat dissipation, low loss, and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

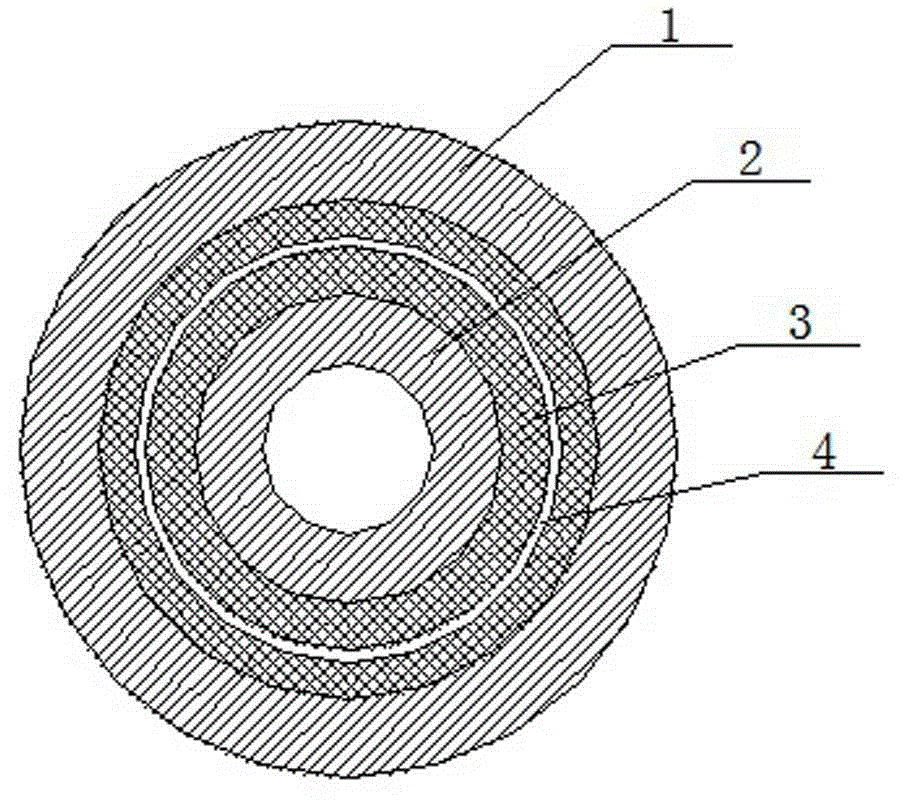

[0017] Such as figure 1 As shown, an epoxy resin insulated transformer according to the present invention includes a high-voltage coil 1 and a low-voltage coil 2 coaxially arranged, the high-voltage coil 1 is arranged outside the low-voltage coil 2, and the high-voltage coil 1 and the A poured epoxy resin insulating layer 3 is provided between the low-voltage coils 2, and the composition and ratio of the epoxy resin insulating layer 3 are:

[0018] 40 parts by weight of epoxy resin;

[0019] 20 parts by weight of curing agent;

[0020] Toughener 10 parts by weight;

[0021] The rest are fillers.

[0022] The filler includes quartz powder, aluminum oxide, aluminum powder, talcum powder, corundum and mica powder.

[0023] The curing agent is a methyl tetrahydrophthalic anhydride curing agent or a methyl hexahydrophthalic anhydride curing agent.

[0024] The toughening agent is asbestos fiber or glass fiber.

[0025] The epoxy resin insulating layer 3 is provided with an an...

Embodiment 2

[0027] Such as figure 1 As shown, an epoxy resin insulated transformer according to the present invention includes a high-voltage coil 1 and a low-voltage coil 2 coaxially arranged, the high-voltage coil 1 is arranged outside the low-voltage coil 2, and the high-voltage coil 1 and the A poured epoxy resin insulating layer 3 is provided between the low-voltage coils 2, and the composition and ratio of the epoxy resin insulating layer 3 are:

[0028] 50 parts by weight of epoxy resin;

[0029] 10 parts by weight of curing agent;

[0030] Toughener 5 parts by weight;

[0031] The rest are fillers.

[0032] The filler includes quartz powder, aluminum oxide, aluminum powder, talcum powder, corundum and mica powder.

[0033] The curing agent is a methyl tetrahydrophthalic anhydride curing agent or a methyl hexahydrophthalic anhydride curing agent.

[0034] The toughening agent is asbestos fiber or glass fiber.

[0035] The epoxy resin insulating layer 3 is provided with an ann...

Embodiment 3

[0037] Such as figure 1 As shown, an epoxy resin insulated transformer according to the present invention includes a high-voltage coil 1 and a low-voltage coil 2 coaxially arranged, the high-voltage coil 1 is arranged outside the low-voltage coil 2, and the high-voltage coil 1 and the A poured epoxy resin insulating layer 3 is provided between the low-voltage coils 2, and the composition and ratio of the epoxy resin insulating layer 3 are:

[0038] 30 parts by weight of epoxy resin;

[0039] 18 parts by weight of curing agent;

[0040] Toughener 9 parts by weight;

[0041] The rest are fillers.

[0042] The filler includes quartz powder, aluminum oxide, aluminum powder, talcum powder, corundum and mica powder.

[0043] The curing agent is a methyl tetrahydrophthalic anhydride curing agent or a methyl hexahydrophthalic anhydride curing agent.

[0044] The toughening agent is asbestos fiber or glass fiber.

[0045] The epoxy resin insulating layer 3 is provided with an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com