A kind of preparation method of supermaterial and supermaterial

A technology of metamaterials and conductor layers, applied in the field of metamaterials and metamaterials preparation, to achieve the effects of large capacity, high process controllability, and controllable electrode properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

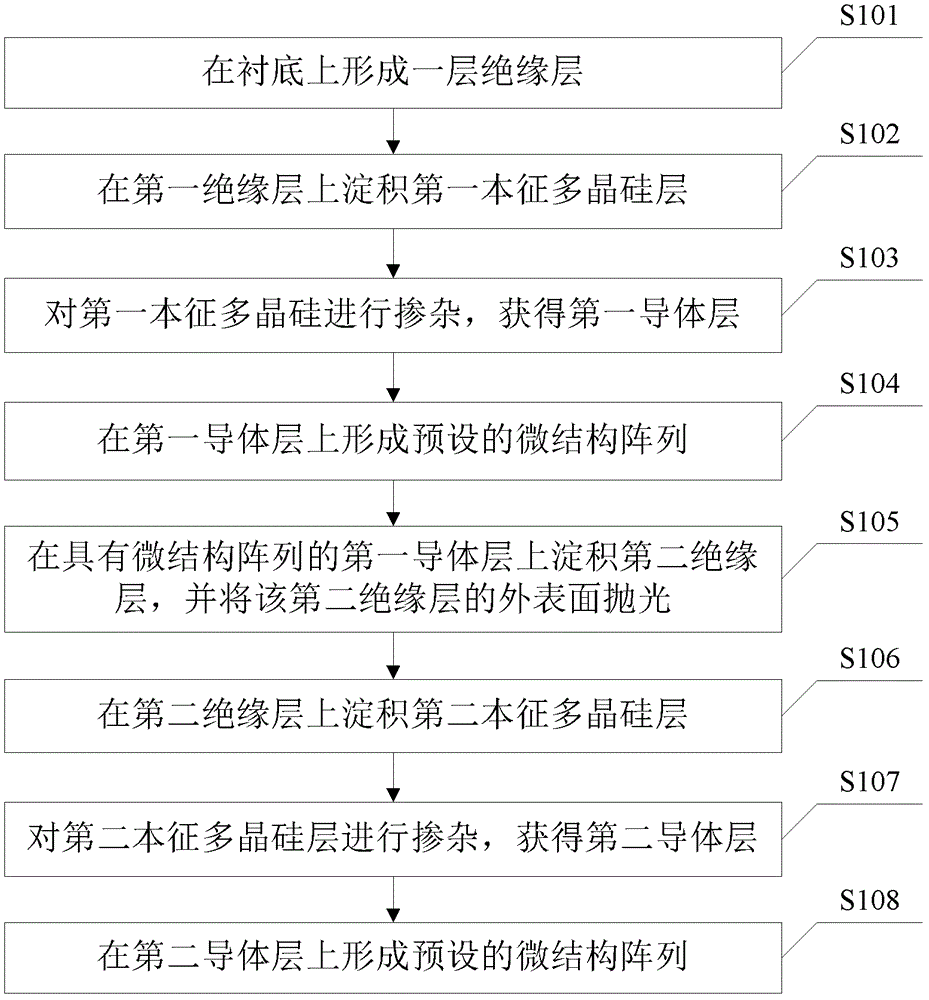

[0029] see figure 1 , is a flow chart of a method for preparing a metamaterial provided in the first embodiment of the present invention, the method of preparation includes:

[0030] S101: forming an insulating layer on a substrate.

[0031] Specifically, an insulating layer can be deposited on the substrate; a layer of insulating layer can also be formed on the substrate, for example, a layer of two layers can be formed on a silicon substrate by dry oxidation or wet oxidation. silicon oxide.

[0032] S102: Deposit a first intrinsic polysilicon layer on the first insulating layer.

[0033] Wherein, the thickness of the deposited first intrinsic polysilicon layer is set according to specific requirements.

[0034] S103: Doping the first intrinsic polysilicon to obtain a first conductor layer.

[0035] For example, P-type or N-type impurities are implanted into the first intrinsic polysilicon layer.

[0036] S104: forming a preset microstructure array on the first conductor...

Embodiment 2

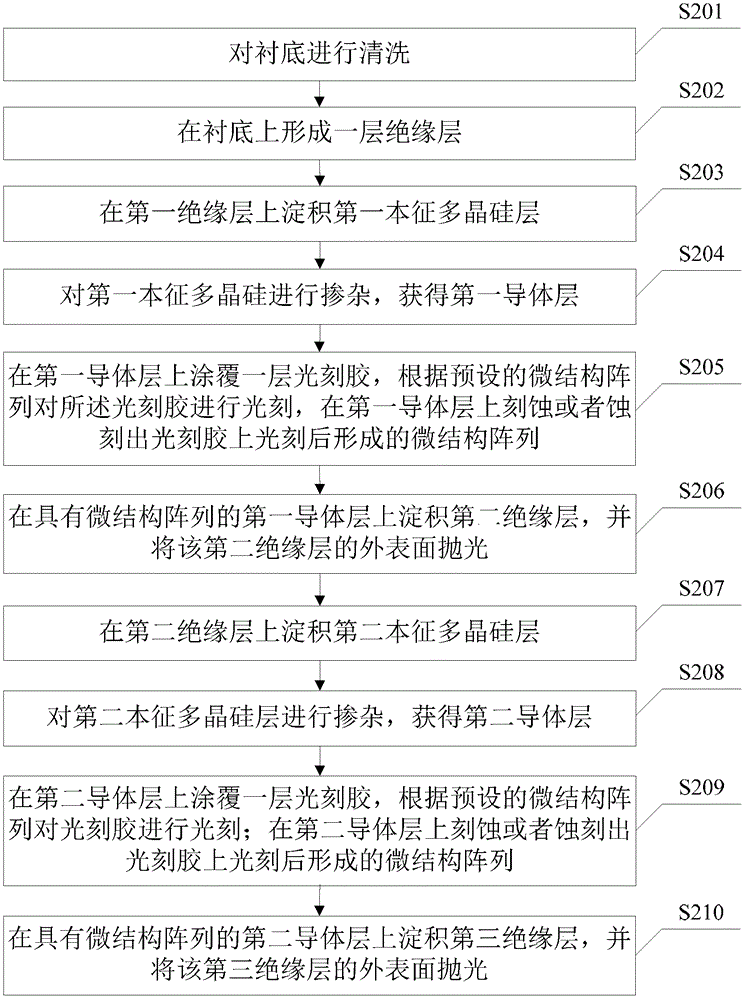

[0049] see figure 2 , is a flow chart of a method for preparing a metamaterial provided in Embodiment 2 of the present invention, and the method includes:

[0050] S201: Cleaning the substrate.

[0051] S202: forming an insulating layer on the substrate.

[0052] Specifically, an insulating layer can be deposited on the substrate; a layer of insulating layer can also be formed on the substrate, for example, a layer of two layers can be formed on a silicon substrate by dry oxidation or wet oxidation. silicon oxide.

[0053] S203: Deposit a first intrinsic polysilicon layer on the first insulating layer.

[0054] Wherein, the thickness of the deposited first intrinsic polysilicon layer is set according to specific requirements.

[0055] S204: Doping the first intrinsic polysilicon to obtain a first conductor layer.

[0056] For example, P-type or N-type impurities are implanted into the first intrinsic polysilicon layer.

[0057] S205: Coating a layer of photoresist on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com