Preparation method of a helical yarn with sensing and capacitive properties

A capacitive characteristic and helical technology, applied in the field of conductive yarn, can solve the problems of incapable of large-scale production, high production cost, and short product life, and achieve the effects of low cost, convenient preparation, and less shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

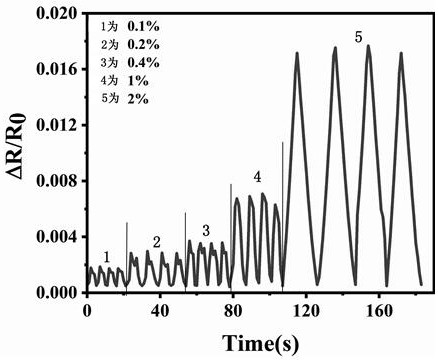

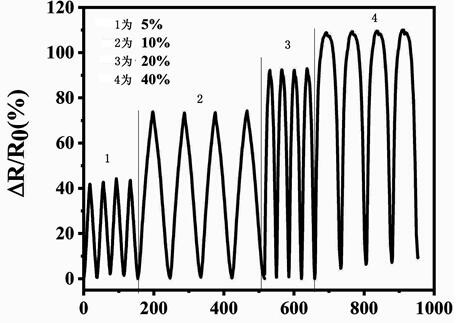

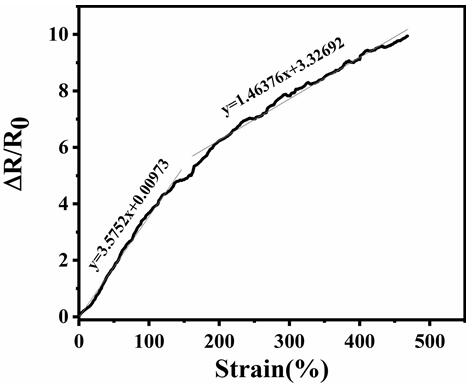

[0034] Embodiment 1: a kind of preparation method of the helical yarn with sensing and capacitance characteristic, it comprises the following steps:

[0035] S1. Soak the thick cotton strips in the carbon nanotube dispersion, ultrasonicate for 50 minutes, then dry them in an oven with a temperature of 70°C, peel them off, and repeat the operation until the resistance per unit length of the thick cotton strips is 80Ω; The fiber length of the thick cotton strip described is 28mm, and the linear density is 1.65tex;

[0036] S2. the cotton spun yarn with a linear density of 14.5tex is prepared by ring spinning;

[0037] S3. Wrap the prepared cotton spun yarn on the spandex filament on the twisting machine to prepare wrapped yarn;

[0038] S4. Immerse the wrapped yarn in a carbon nanotube dispersion of 0.3wt% by weight, dry it, and repeat the operation 4 times until the resistance per unit length is 315Ω;

[0039] S5. Prepare 1mol / L, 15mL pyrrole solution, and add dispersant CTAB...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of the spiral yarn with sensory and capacitive properties, it comprises the following steps:

[0042] S1. Soak the thick cotton strips in the carbon nanotube dispersion, ultrasonicate for 70 minutes, then dry them in an oven with a temperature of 90°C, peel them off, and repeat the operation until the resistance per unit length of the thick cotton strips is 80Ω; The fiber length of the thick cotton strip described is 28mm, and the linear density is 1.65tex;

[0043] S2. the cotton spun yarn with a linear density of 14.5tex is prepared by ring spinning;

[0044]S3. Wrap the prepared cotton spun yarn on the rubber band on the twisting machine to prepare wrapped yarn;

[0045] S4. Immerse the wrapped yarn in a carbon nanotube dispersion of 0.3wt% by weight, dry it, and repeat the operation 4 times until the resistance per unit length is 315Ω;

[0046] S5. Prepare 1mol / L, 15mL of pyrrole solution, and add 0.052g of dispersant CTA...

Embodiment 3

[0048] Embodiment 3: a kind of preparation method of the helical yarn with sensing and capacitance characteristic, it comprises the following steps:

[0049] S1. Soak the thick cotton strips in the carbon nanotube dispersion, ultrasonicate for 60 minutes, then dry them in an oven with a temperature of 80°C, peel them off, and repeat the operation until the resistance per unit length of the thick cotton strips is 80Ω; The fiber length of the thick cotton strip described is 28mm, and the linear density is 1.65tex;

[0050] S2. the cotton spun yarn with a linear density of 14.5tex is prepared by ring spinning;

[0051] S3. Wrap the prepared cotton spun yarn on the Lycra filament on the twisting machine to prepare wrapped yarn;

[0052] S4. immerse the wrapped yarn in a manganese dioxide dispersion of 0.3wt% by weight, dry it, and repeat the operation 4 times until the resistance per unit length is 315Ω;

[0053] S5. Prepare 1mol / L, 15mL pyrrole solution, and add dispersant CTAB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com