A kind of graphene film and continuous preparation method thereof

A graphene film and graphene technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of graphene being difficult to form a large-area continuous film, and overcome the difficulty of large-area continuous film formation. Low equipment requirements and the effect of shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of polytetrafluoroethylene dispersion:

[0032] Add 1.4706g of polytetrafluoroethylene concentrated dispersion (60wt%) and 50mL of ethanol into a beaker, and stir continuously at room temperature until the dispersion is uniform to obtain dispersion A, that is, polytetrafluoroethylene dispersion (2.2wt%).

[0033] 2. Preparation of graphene dispersion:

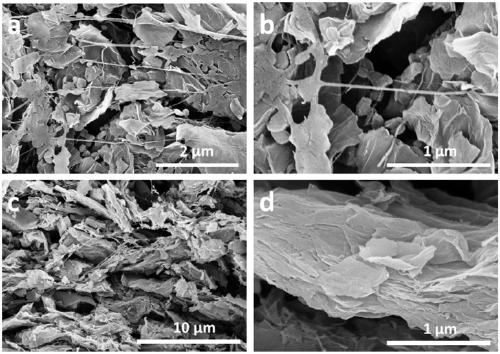

[0034] Add 5g of graphene to the beaker, add ethanol continuously, and add ethanol under stirring until the graphene powder can be completely immersed in ethanol. After magnetic stirring at room temperature and ultrasonic dispersion, the power was 80W, and the ultrasonic time was 1 hour to obtain dispersion B, namely graphene dispersion (concentration: 3.5wt%).

[0035] 3. Roller slurry preparation:

[0036] Add the dispersion A to the dispersion B, stir at room temperature, put it on the heating table after being uniform, heat to 70°C and keep stirring to volatilize the ethanol until the slurry reaches ...

Embodiment 2

[0045] 1. Preparation of polytetrafluoroethylene dispersion:

[0046]Add 1.4706g of polytetrafluoroethylene concentrated dispersion (60wt%) and 50mL of ethanol into a beaker, and stir continuously at room temperature until the dispersion is uniform to obtain dispersion A, that is, polytetrafluoroethylene dispersion (2.2wt%).

[0047] 2. Preparation of graphene dispersion:

[0048] Add 3g of graphene to the beaker, add ethanol continuously, and add ethanol under stirring until the graphene powder can be completely immersed in ethanol. At room temperature, after magnetic stirring and ultrasonic dispersion, the power is 50W, and the ultrasonic time is 1 hour to obtain dispersion B, namely graphene dispersion (concentration: 3.5wt%).

[0049] 3. Roller slurry preparation:

[0050] Add the dispersion A to the dispersion B, stir at room temperature, put it on the heating table after being uniform, heat to 70°C and keep stirring to volatilize the ethanol until the slurry reaches a ...

Embodiment 3

[0058] 1. The preparation of polytetrafluoroethylene dispersion is the same as in Example 1.

[0059] 2. Preparation of graphene dispersion:

[0060] Add 5g of graphene into the beaker, then add deionized water, and keep stirring until the graphene sheets are completely immersed in deionized water. After ultrasonic dispersion by the probe, the power is 80W, and the ultrasonic time is 1h, to obtain a dispersion of graphene in water (concentration: 2wt%).

[0061] 3. Preparation of roll-pressed slurry:

[0062] Mix the polytetrafluoroethylene dispersion and the graphene dispersion, stir continuously until they are uniform, put them on the heating table, heat to 70°C and stir continuously to volatilize the deionized water until the slurry reaches a semi-solid state and meets the requirements of the roller. Until the pressure condition; the solid content of the finally obtained slurry is 60wt%.

[0063] 4. Preparation of graphene film:

[0064] Take the graphene-polytetrafluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com