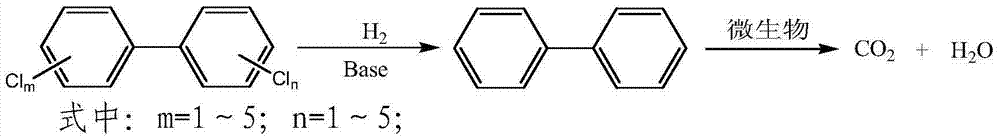

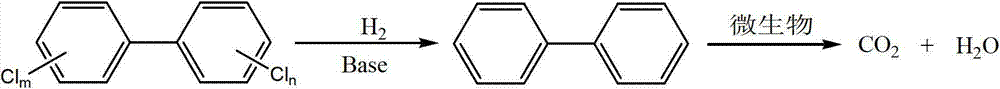

Process for combination degradation of polychlorinated biphenyls

A technology for polychlorinated biphenyls and dechlorination, which is applied in the direction of protection devices against harmful chemicals, and achieves the effects of mild reaction conditions, no secondary pollution, and rapid degradation of biphenyls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

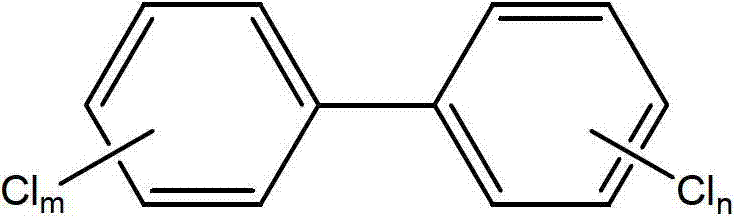

Method used

Image

Examples

Embodiment 1

[0033] 1) Preparation of hydrodechlorination catalyst: 2.48g FeSO 4 ·7H 2 O and 0.83g PdCl 2 Dissolve in 200ml of 1.0mol / L dilute hydrochloric acid, add 5g of activated carbon and mix well, then add Na 2 CO 3 solution, adjust the pH to 10, stir for 30 min, and wash with deionized water several times until no Cl ions exist in the filtrate. Then add 2.1g NaBH under stirring condition 4 Reduction was carried out for 1 h, washed with deionized water several times until the filtrate was neutral, and dried at room temperature to obtain a 1.0%Pd-1.0%Fe / C catalyst. Palladium-iron / carbon catalysts with different contents prepared in the same way are listed in Table 1.

[0034] According to the preparation process of the catalyst described in Example 1, except that the active component and the carrier are different, all the other processes are the same. The preparation can obtain supported catalysts with different carriers and different active components. The prepared catalyst is l...

Embodiment 2

[0042] Take by weighing the 1.0%Ni-1.0%Fe / C catalyst that 0.1g table 1 prepares, join in the there-necked flask of 100ml, add the 4-chlorobiphenyl / ethanol-water solution 80ml that concentration is 200ppm, make under magnetic stirrer stirring The reactants were adsorbed for 15 minutes; at the same time, N 2 Replace the air in the reactor, do this three times, and then pass H 2 , H 2 The flow rate is controlled within the range of 10ml / min, and the basic proton absorbent used is sodium hydroxide, but in order to ensure that the second step oxidation reaction can be carried out relatively quickly, the molar ratio of the amount of alkali to the amount of the reaction substrate is 1.1 : 1, the reaction temperature is controlled at 30°C, and the reaction pressure is normal pressure; centrifuge the reaction solution, adjust the pH value of the reaction solution to 7.0, and perform the hydrodechlorination reaction for 120min;

[0043] After the reaction, 9 ml of the reaction solutio...

Embodiment 3

[0045] Weigh 0.1g of the 1.0%Pd-1.0%Fe / C catalyst prepared in Table 1, join in a 100ml three-necked flask, add 80ml of PCB / ethanol-water solution with a concentration of 200ppm, and make the reaction under magnetic stirrer stirring The substance was adsorbed for 15min; at the same time, N 2 Replace the air in the reactor, do this three times, and then pass H 2 , H 2 The flow rate is controlled within the range of 10ml / min, and the basic proton absorbent used is sodium hydroxide, but in order to ensure that the second-step oxidation reaction can be carried out relatively quickly, the molar ratio of the amount of alkali to the amount of Cl in the reaction substrate The ratio is 1.1:1, the reaction temperature is controlled at 30°C, and the reaction pressure is normal pressure; centrifuge the reaction liquid, adjust the pH value of the reaction liquid to 7.0, and carry out the hydrodechlorination reaction for 180 min;

[0046] After the reaction, 9 ml of the reaction solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com