Method and device for eliminating nanoparticles on surfaces of substrates under assistance of laser

A nanoparticle and laser-assisted technology, which is applied in the direction of cleaning methods and appliances, laser welding equipment, chemical instruments and methods, etc., can solve the problems of easily damaged substrates and difficult removal of particles, so as to avoid pollution and damage, avoid damage, avoid Effects of matrix damage and contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

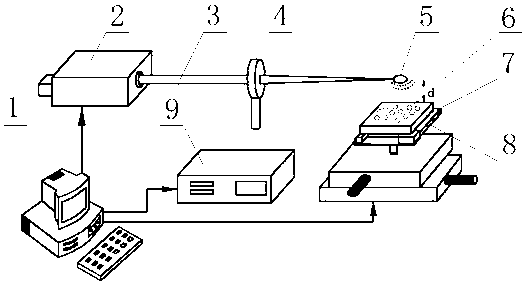

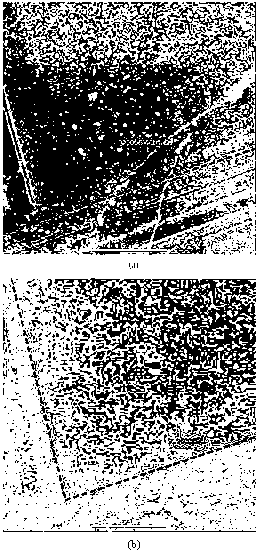

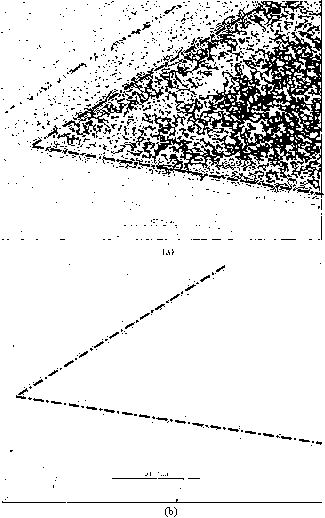

[0033] The following is an example of laser-assisted removal of nanoparticles on the surface of a substrate. Thales lasers are used to remove ceria particles (60 nm in diameter) from the surface of a silicon wafer. The vertical distance from the upper surface of the silicon wafer to the focal point of the convex lens is 1.5 mm. , wavelength 1064 nm, repetition frequency 10 Hz, pulse width 5 ns) focusing to form plasma expansion to remove nanoparticles on the surface of the silicon wafer substrate; figure 2 (a) is the surface of the silicon wafer with cerium oxide particles (60 nm in diameter) attached to it before laser cleaning, and (b) is the surface of the silicon wafer after laser cleaning. The dotted line in the figure is the dividing line between the non-laser cleaning area and the laser cleaning area; From the figure, we can see that after the laser radiation, the cerium oxide particles (60 nm in diameter) on the surface of the silicon wafer are effectively removed, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Pulse energy | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com