Partial conversion system for carbonic oxide and process control method thereof

A carbon monoxide and conversion furnace technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of not meeting the requirements of the post-system, scaling, and low CO conversion rate, so as to avoid scaling The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

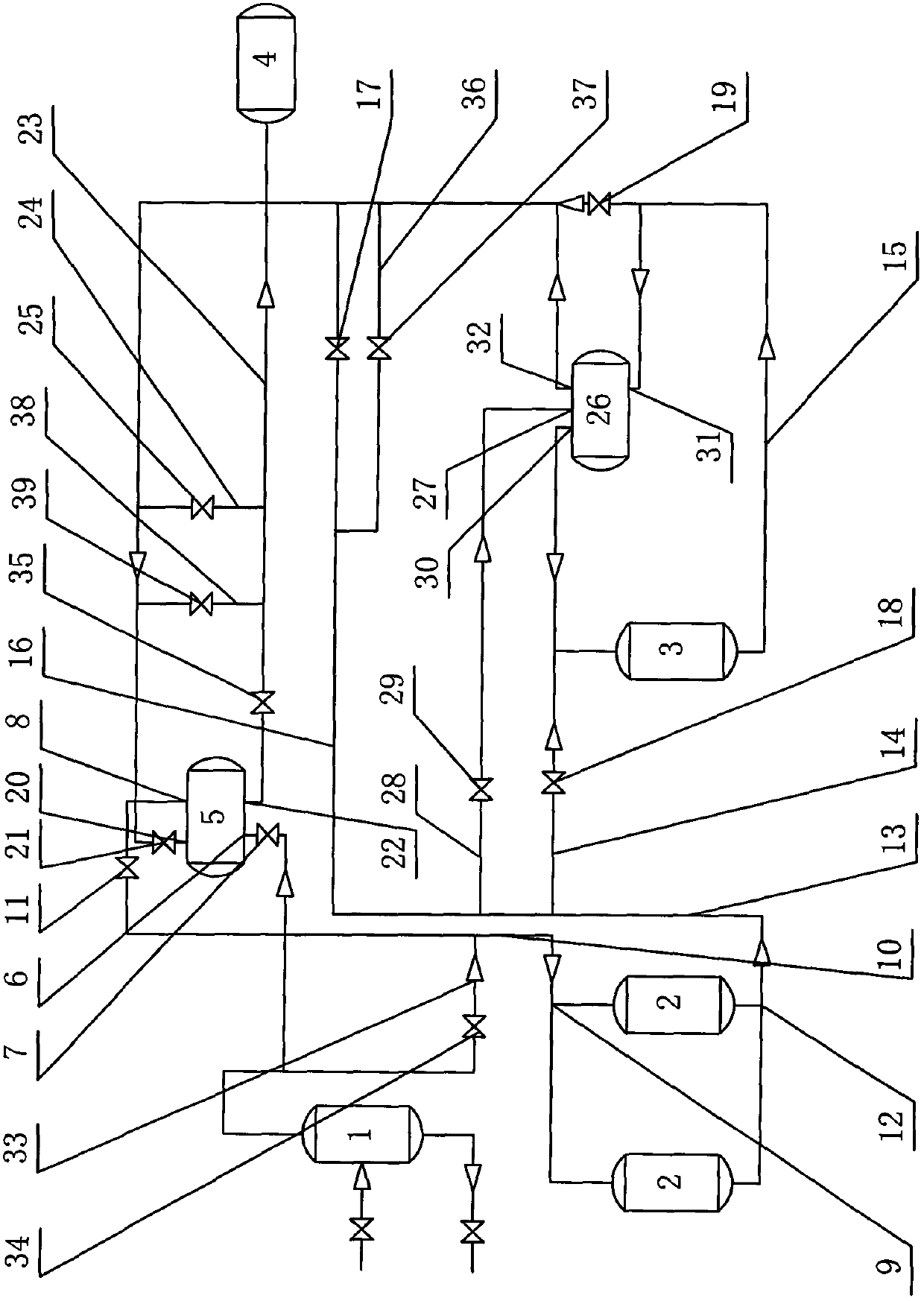

[0017]Embodiment 1: Partial carbon monoxide shift system, which includes a shift gas-liquid separator 1, two pre-shift furnaces 2 connected in parallel, a shift furnace 3, a purified gas heater 4, an auxiliary feed gas heater 26 and a feed gas heater 5 , the raw material gas outlet of the conversion gas-liquid separator 1 is connected to the low-temperature raw gas inlet 6 of the raw gas heater 5, the low-temperature raw gas inlet 6 is provided with a low-temperature raw gas inlet gate valve 7, and the low-temperature raw gas outlet of the raw gas heater 5 8 is connected to the pre-shift furnace inlet 9 through the pre-shift furnace inlet main pipe 10, the low-temperature raw material gas outlet 8 is provided with a low-temperature raw material gas outlet gate valve 11, the pre-shift furnace outlet 12 is connected to one end of the pre-shift furnace outlet main pipe 13, and the pre-shift furnace The other end of the outlet main pipe 13 is respectively connected to the main conv...

Embodiment 2

[0018] Embodiment 2: a kind of carbon monoxide partial conversion process control method, it is operated by the following steps: (1) change the raw material gas split flow that the gas-liquid separator separates; (2) carbon ash removal in the pre-shift furnace; (3) raw material Gas shunt heat exchange completes partial carbon monoxide conversion; (4) gas shunt after mixing;

[0019] (1) Raw material gas splitting separated by shift gas-liquid separator: the raw gas separated by shift gas-liquid separator 1 goes to the raw gas heater 5, and is mixed with the outlet main pipe 15 from the shift furnace in the raw gas heater 5 After the heat exchange, the post-gas flows into the pre-shift furnace inlet main pipe 10, and then enters the pre-shift furnace 2; or the raw material gas directly enters the pre-shift furnace inlet main pipe 10, and then enters the pre-shift furnace 2; (2) carbon ash removal in the pre-shift furnace: The carbon ash is removed from the raw material gas in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com