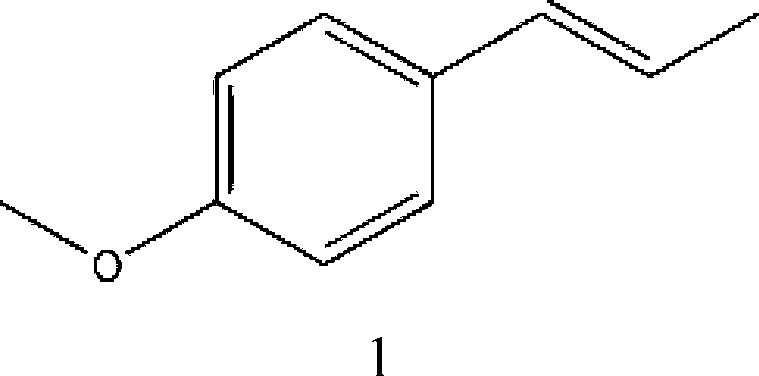

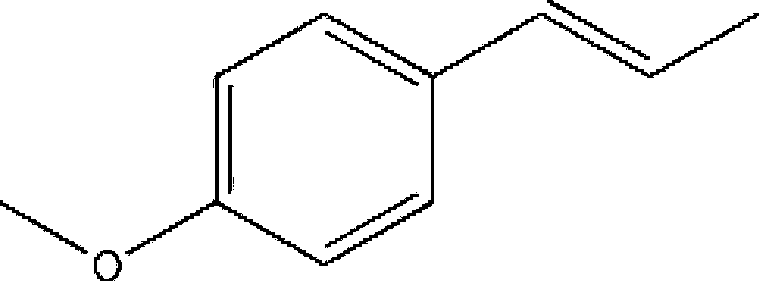

Synthesis method of anethole

A synthesis method and technology of synthesis reaction, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of difficult promotion, harsh equipment requirements, high cost, low temperature, reduced requirements, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

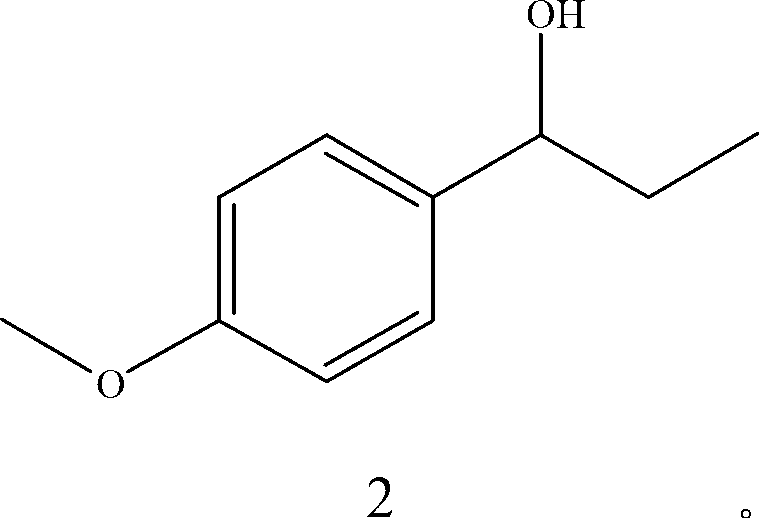

[0038] Take each material according to the following weight ratio:

[0039] p-methoxyphenylpropanol 500kg

[0040] Dehydrating agent - anhydrous sodium sulfate 1kg

[0041] With water agent - toluene 1500kg

[0042] Put the weighed dehydrating agent and water-carrying agent in the reaction kettle, stir and mix and heat to 100°C to reflux, then add p-methoxyphenylpropanol dropwise to the reflux mixture, and control the dropping time to 6-8 Hours; after the dropwise addition of p-methoxyphenylpropanol, keep the temperature between 100-150°C for 30min-2 hours, and stop the reaction when no water flows out of the water separator.

[0043] The above reaction mixture was sampled and detected by LC / MS, and the reaction conversion rate was 90.2%; the obtained reaction mixture was post-processed to obtain 400 kg of the product anethole, and the product yield was 90.1%.

Embodiment 2

[0045] Take each material according to the following weight ratio:

[0046] p-methoxyphenylpropanol 500kg

[0047] Dehydrating agent - anhydrous magnesium sulfate 1kg

[0048] With water agent - benzene 4000kg

[0049]Put the weighed dehydrating agent and water-carrying agent in the reaction kettle, stir and mix and heat to 80°C to reflux, then add p-methoxyphenylpropanol dropwise to the reflux mixture, and control the dropping time to be 6-8 Hours; after the dropwise addition of p-methoxyphenylpropanol, keep the temperature between 90-150°C for 30min-2 hours, and stop the reaction when no water flows out of the water separator.

[0050] The above reaction mixture was sampled and detected by LC / MS, and the reaction conversion rate was 90.6%; the obtained reaction mixture was post-processed to obtain 401 kg of anethole product, and the product yield was 90.1%.

Embodiment 3

[0052] Take each material according to the following weight ratio:

[0053] p-methoxyphenylpropanol 800kg

[0054] Dehydrating agent - calcium hydride 1kg

[0055] With water agent - p-xylene 2400kg

[0056] Put the weighed dehydrating agent and water-carrying agent in the reaction kettle, stir and mix and heat to 115°C to reflux, then add p-methoxyphenylpropanol dropwise to the reflux mixture, and control the dropping time to be 6-8 Hours; after the dropwise addition of p-methoxyphenylpropanol, keep the temperature between 120-150°C for 30min-2 hours, and stop the reaction when no water flows out of the water separator.

[0057] The above reaction mixture was sampled and detected by LC / MS, and the reaction conversion rate was 90.3%; the obtained reaction mixture was post-processed to obtain 634 kg of anethole, and the product yield was 89.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com