Dilatation-retardant water-absorbent resin and preparation method thereof

A water-absorbent resin and slow-swelling technology, applied in the field of resin, can solve the problems of large specific surface area, small particle size of water-absorbent resin, and impracticality, and achieve the effect of strong operability and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

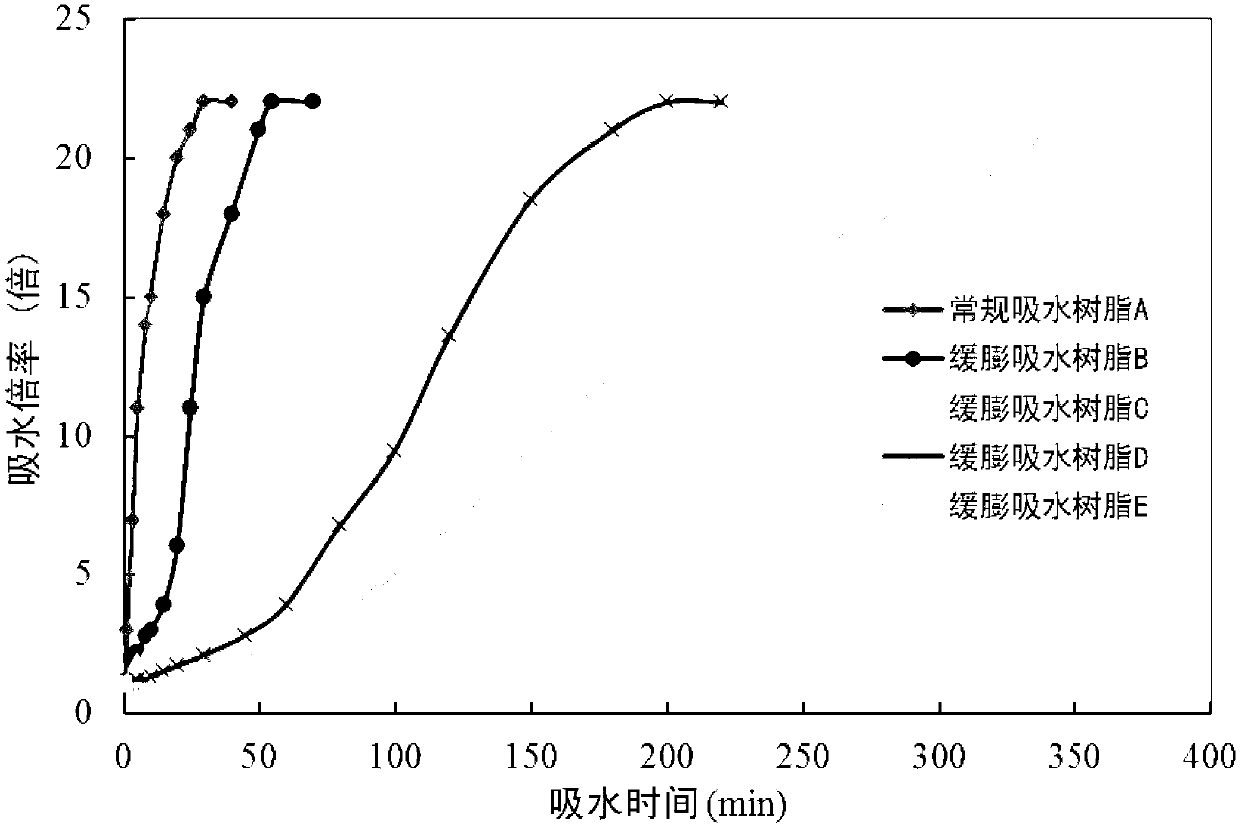

Embodiment 1

[0029] Add 77g of distilled water, 12g of monomeric acrylic acid, 12g of acrylamide, and 0.8g of cross-linking agent N,N'-methylene bisacrylamide in turn under stirring in the reaction vessel. In a water bath, add 0.5 g of initiator ammonium persulfate, and react for 30 minutes to obtain a solid gel block product, which is dried, pulverized, and granulated to obtain a powdery conventional water-absorbent resin A.

Embodiment 2

[0031] Add 3g of gum arabic and 3g of polyethylene glycol into 94g of water, fully dissolve, and then use the aqueous solution dissolved in gum arabic and polyethylene glycol as a spray liquid to fluidize and spray the self-made conventional water-absorbent resin A, fluidize The bed spraying temperature is 40°C, and the atomization pressure of the fluidized bed spraying is 1.2 bar. When the weight of the water-absorbent resin increases by 10%, the coating is stopped to obtain the slow-swelling water-absorbent resin B.

Embodiment 3

[0033] With 3g hydroxypropyl methylcellulose and 1.5g povidone, join in 95.5g ethanol (95% of ethanol concentration), after fully dissolving, then use the ethanol that dissolves hydroxypropyl methylcellulose and povidone The solution is used as a spraying liquid, and the self-made conventional water-absorbing resin A is fluidized and sprayed. The temperature of the fluidized bed spraying is 25 ° C, and the atomization pressure of the fluidized bed spraying is 0.7 bar. When the weight of the water-absorbing resin increases by 32%, stop the coating Cover to obtain slow-swelling water-absorbent resin C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com