Treatment method of sweet corn seeds

A treatment method and technology for sweet corn, applied in the directions of seed and rhizome treatment, seed immunity, botanical equipment and methods, etc., can solve the problems of poor germination rate improvement effect, etc., to speed up repair, prevent bacterial contamination of seeds, and promote germination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

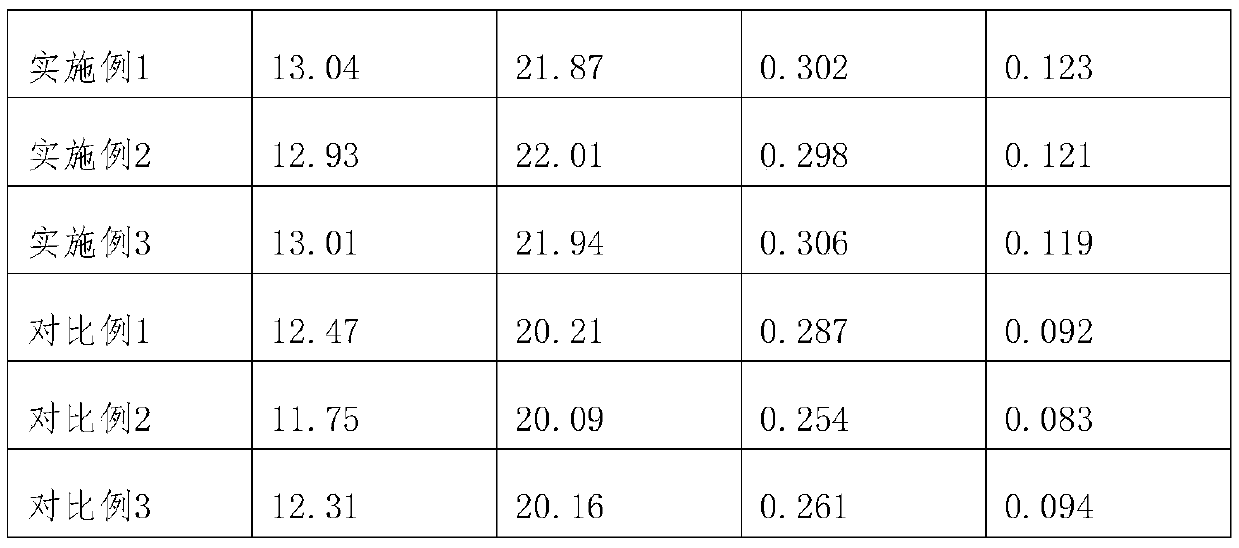

Embodiment 1

[0023] A processing method for sweet corn seeds, specifically comprising the following processes:

[0024] (1) put the Jinyutian No. 1 corn seed of harvest into the konjac powder film-forming agent and soak for 6min, take out the film layer on the seed surface to dry naturally, and obtain the initial coated seed; wherein, the konjac powder film-forming agent is by weight It is made by mixing 30kg konjac flour, 20kg activated carbon, 3kg sodium alginate, 8kg sweet corn flour and 120kg water;

[0025] (2) The first coated seeds are placed in the nutrient solution and soaked for 50min, then put into the konjac flour film-forming agent soaking solution after taking out and dipped in for 5s; wherein, the nutrient solution is calculated by 0.1kg indole acetic acid in parts by weight , 3kg cysteine, 1kg magnesium sulfate, 1kg citric acid chelated manganese, 3kg vitamin C, 3kg vitamin A, 50kg water;

[0026] (3) The seeds dipped in step (2) are put into the coating machine immediatel...

Embodiment 2

[0031] A processing method for sweet corn seeds, specifically comprising the following processes:

[0032] (1) Put the harvested Yuetian No. 13 corn seeds into the konjac powder film-forming agent and soak for 8 minutes, take out the film layer on the seed surface to dry naturally, and obtain the initial coated seed; wherein, the konjac powder film-forming agent is by weight It is made by mixing 32kg konjac flour, 24kg activated carbon, 4kg sodium alginate, 10kg sweet corn flour and 130kg water;

[0033] (2) The first coated seeds are placed in the nutrient solution and soaked for 55min, then put into the konjac flour film-forming agent soaking solution after taking out and dipped in for 5s; wherein, the nutrient solution is calculated by 0.12kg indole acetic acid in parts by weight , 4kg cysteine, 1.2kg magnesium sulfate, 1.5kg citric acid chelated manganese, 4kg vitamin C, 3.5kg vitamin A, 56kg water;

[0034] (3) The seeds dipped in step (2) are put into the coating machin...

Embodiment 3

[0039] A processing method for sweet corn seeds, specifically comprising the following processes:

[0040] (1) putting the sweet jade No. 2 seeds of harvest into the konjac powder film-forming agent and soaking for 10min, taking out the film layer on the seed surface to dry naturally, and obtaining the initial coated seed; wherein, the konjac powder film-forming agent is made of 40kg of konjac flour, 30kg of activated carbon, 5kg of sodium alginate, 12kg of sweet corn flour, and 150kg of water are mixed;

[0041](2) The first coated seeds are placed in the nutrient solution and soaked for 60min, then put into the konjac flour film-forming agent soaking solution after taking out and dipped in for 5s; wherein, the nutrient solution is calculated by 0.2kg indole acetic acid in parts by weight , 5kg cysteine, 2kg magnesium sulfate, 2kg citric acid chelated manganese, 5kg vitamin C, 5kg vitamin A, 60kg water;

[0042] (3) the seeds dipped in step (2) are put into the coating machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com