Method for producing xylitol through fermenting lees hydrolysate by using pichia guilliermondii

A yeast fermentation and hydrolyzate technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of seriousness, pollution, and high production process costs, and achieve fast reaction, strong anti-interference ability, and product separation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

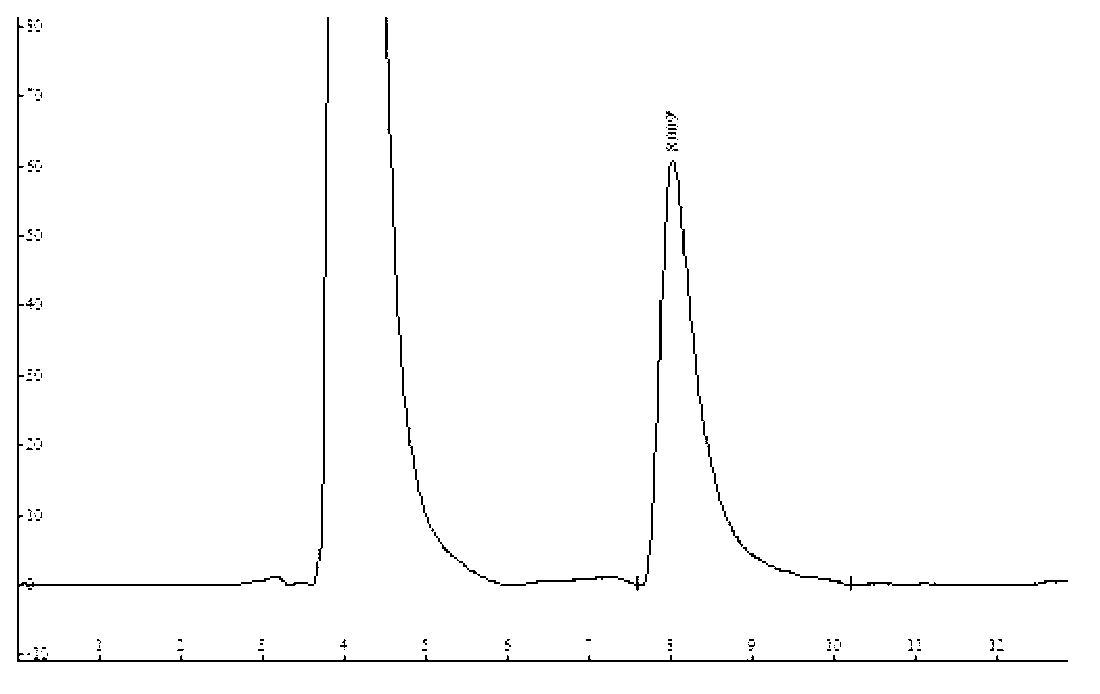

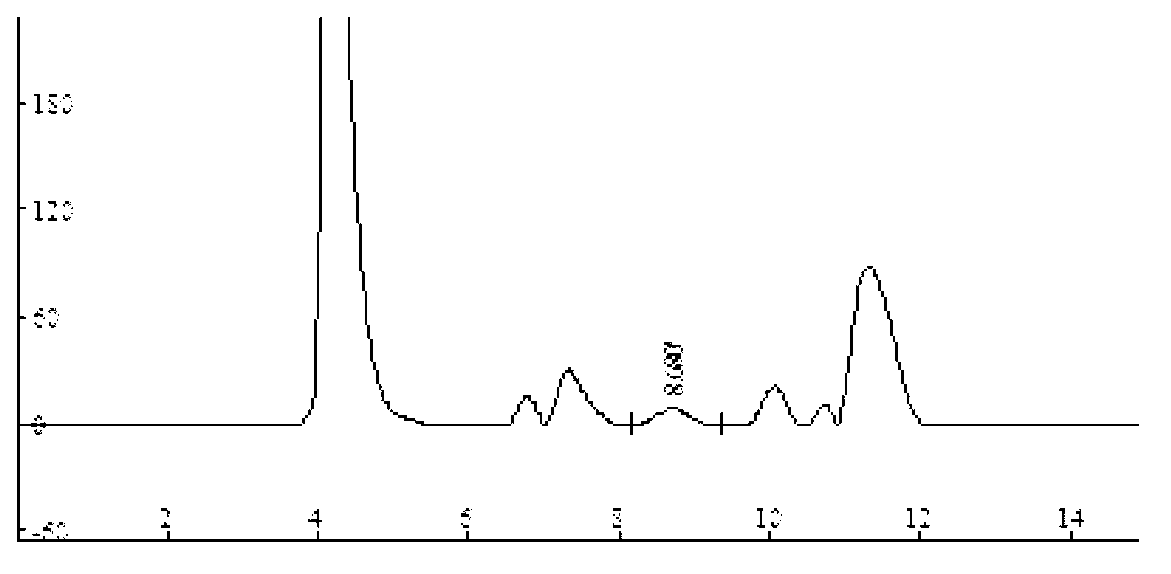

Image

Examples

Embodiment 1

[0029] (1) Preparation of distiller's grain hydrolyzate

[0030] Grind the dried distiller's grains to a particle size of 40 mesh, mix it with 0.1% NaOH solution at a ratio of 1:5 (w / v), heat and boil for 1 h under stirring, filter with a filter cloth after cooling, discard the filtrate, and use Wash the filter residue with clean water, then boil the filter residue with 1000 mL of water for 1 h, filter, and remove the filter residue after removing ash to be hydrolyzed in the next step; use a mixture of 1% HCl and 1% H 3 PO 4 The composed mixed acid hydrolyzed distiller's grains, the hydrolysis temperature is 100°C, the solid-to-liquid ratio is 1:10 (w / v), hydrolyzed for 2 h; the hydrolyzate is concentrated at 85°C until the xylose content is about Ratio (w / v) adding activated carbon for decolorization, concentration and decolorization can increase the initial xylose concentration in the hydrolyzate, and also remove harmful substances such as organic acids, furfural and pigmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com