Closed pelletization system for liquid copper matte

A technology of granulation and copper matte, which is applied in the direction of rotary drum furnace, crucible furnace, furnace, etc., can solve the problems of increased production and maintenance costs, unsafe operation, equipment corrosion, etc., so as to save drying and dehydration procedures and prevent damage The effect of strong corrosion and prolonging the service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

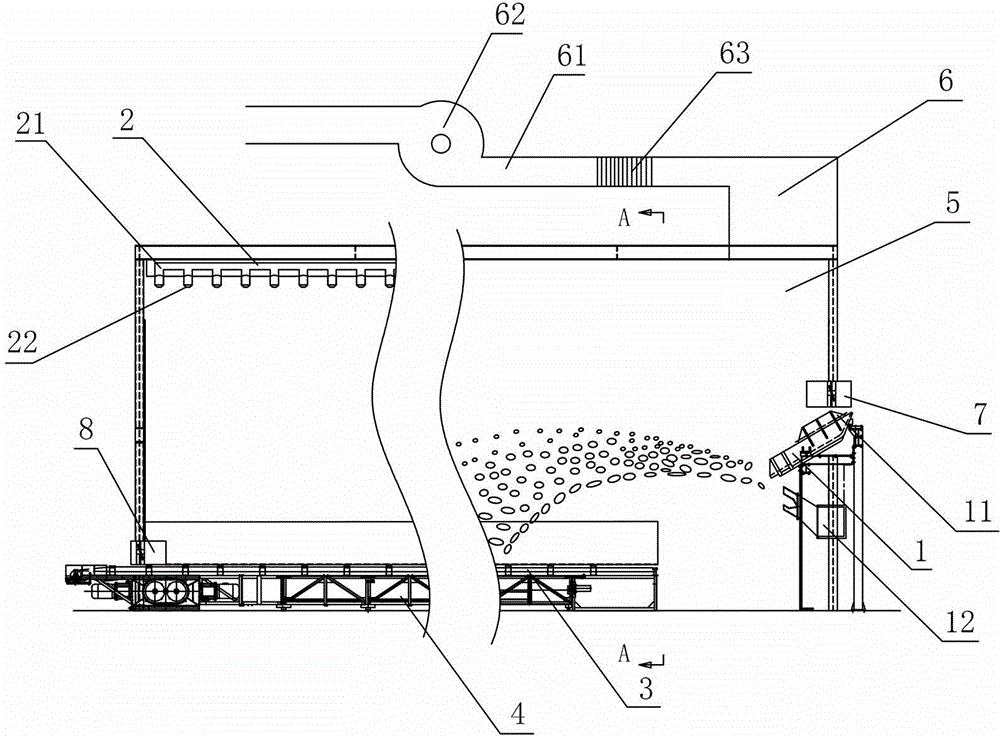

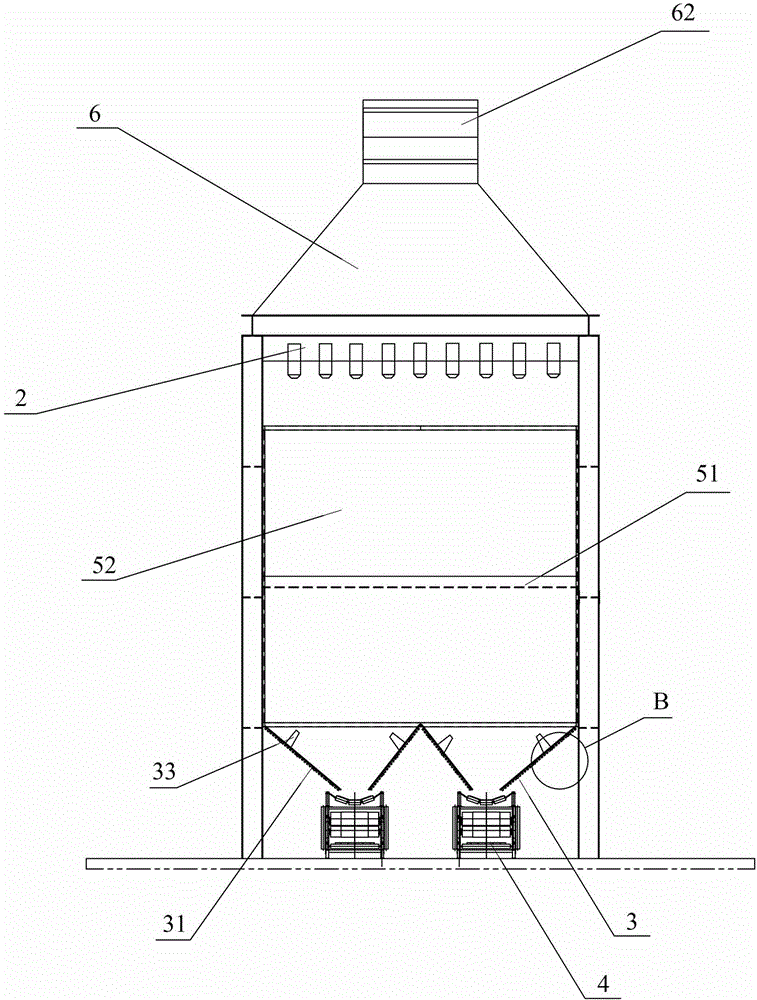

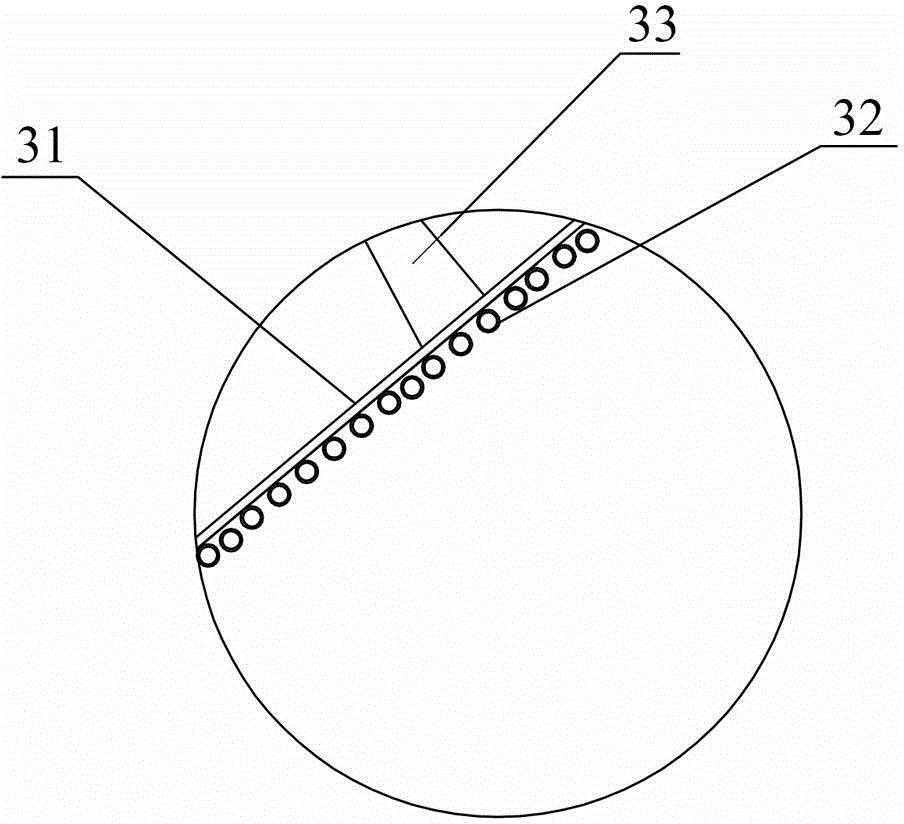

[0025] Figure 1 to Figure 4 An embodiment of a closed granulation system for liquid copper matte of the present invention is shown, the closed granulation system includes a closed box 5 and an air quenching granulation device 1 and a spray device 2 installed in the closed box 5 , a particle collection device 3 and a transport device 4, the air quenching granulation device 1 is arranged at one end of the airtight box body 5, the feeding end of the air quenching granulation device 1 extends outside the airtight box body 5, and the spraying device 2 is arranged at the airtight box body The top of the body 5, the transport device 4 is located at the bottom of the airtight box 5, the output end of the transport device 4 extends outside the airtight box 5, the particle collection device 3 is in the shape of a V-shaped groove with an opening at the bottom, and the bottom opening of the particle collection device 3 is located at Transporter 4 above. The process of liquid copper matt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com