Cyanide-free alkaline bright copper plating solution and preparation method and electroplating process thereof

A solution and alkaline technology, which is applied in the field of cyanide-free alkaline bright copper plating solution, can solve the problems that the performance of the plating layer cannot be achieved, the bonding force between the copper plating layer and the substrate is poor, and the ability to resist impurities is weak, so as to achieve anti-impurity Strong ability, good binding force, not easy to turbid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred cyanide-free alkaline bright copper plating solution, preparation method and process of the present invention will be described in detail below, but it is not a limitation of the present invention. For those skilled in the art, some non-essential improvements and improvements made according to the above-mentioned content of the invention Adjustments are also considered to fall within the protection scope of the present invention.

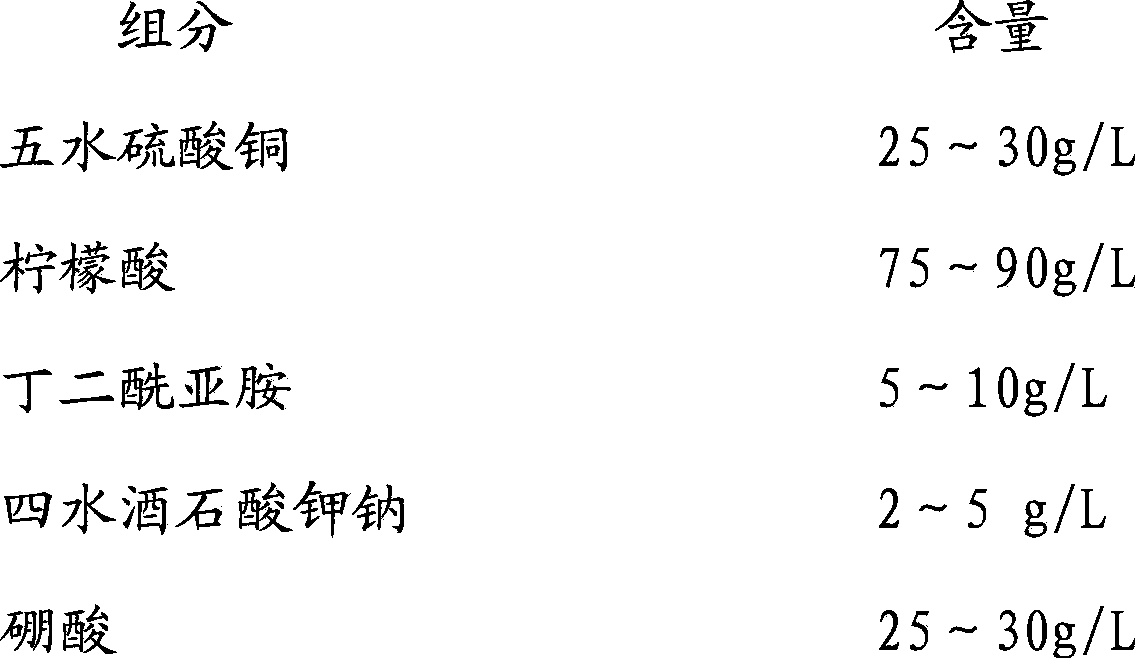

[0036] First, the components of the cyanide-free alkaline bright copper plating solution of the present invention are described and selected in detail.

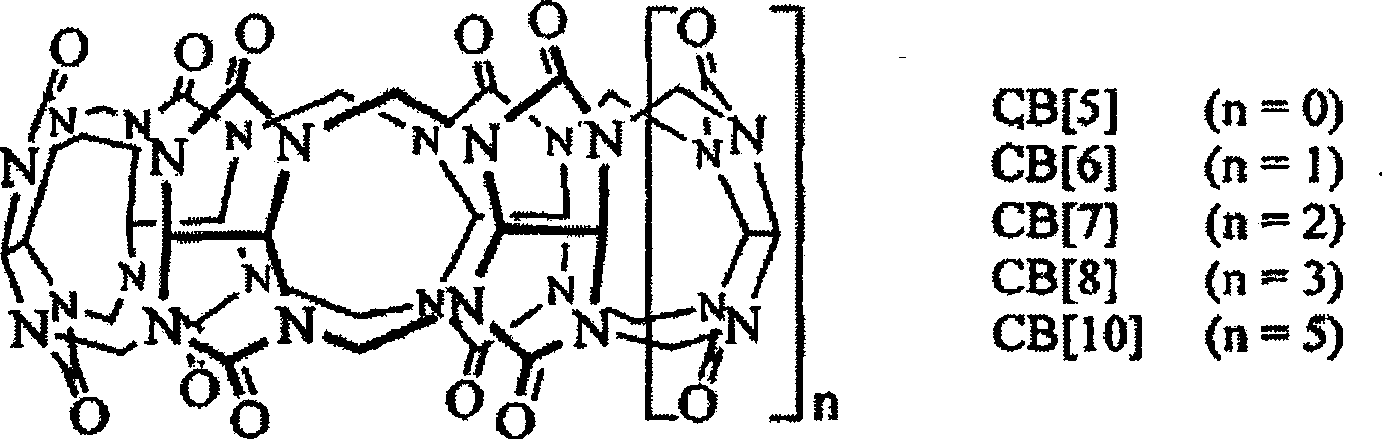

[0037] 1. In the alkaline bright copper plating solution of the present invention, divalent copper salt (copper sulfate) and potassium hydroxide are the main components. However, copper sulfate cannot be directly added to the potassium hydroxide solution, and it will precipitate rapidly, so it is necessary to coordinate the copper salt with the complexing agent before adding it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com