Sintered rare earth permanent magnetic material and preparation method thereof

A rare-earth permanent magnet and non-rare-earth technology, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of magnet deformation, material waste, and can only reach the millimeter level, so as to improve coercive force and high processing efficiency , The effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

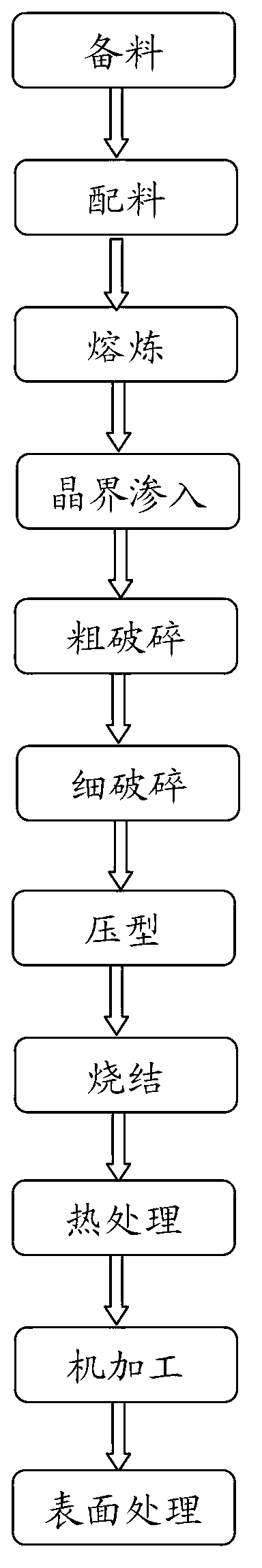

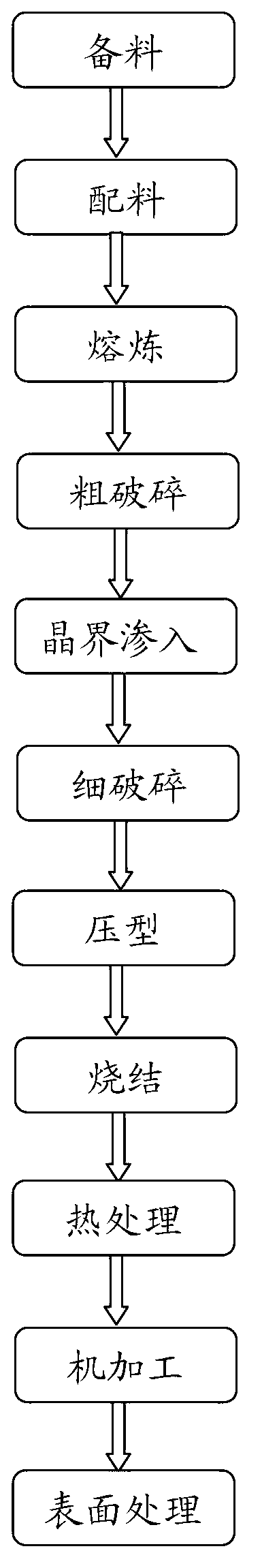

[0033] The preparation method of sintered rare earth permanent magnet material of the present invention is:

[0034] 1) Material preparation: Provide raw materials with a purity greater than 99wt%, and perform shot blasting for 10-60 minutes to clean the oxide layer on the surface to further improve the quality of raw materials.

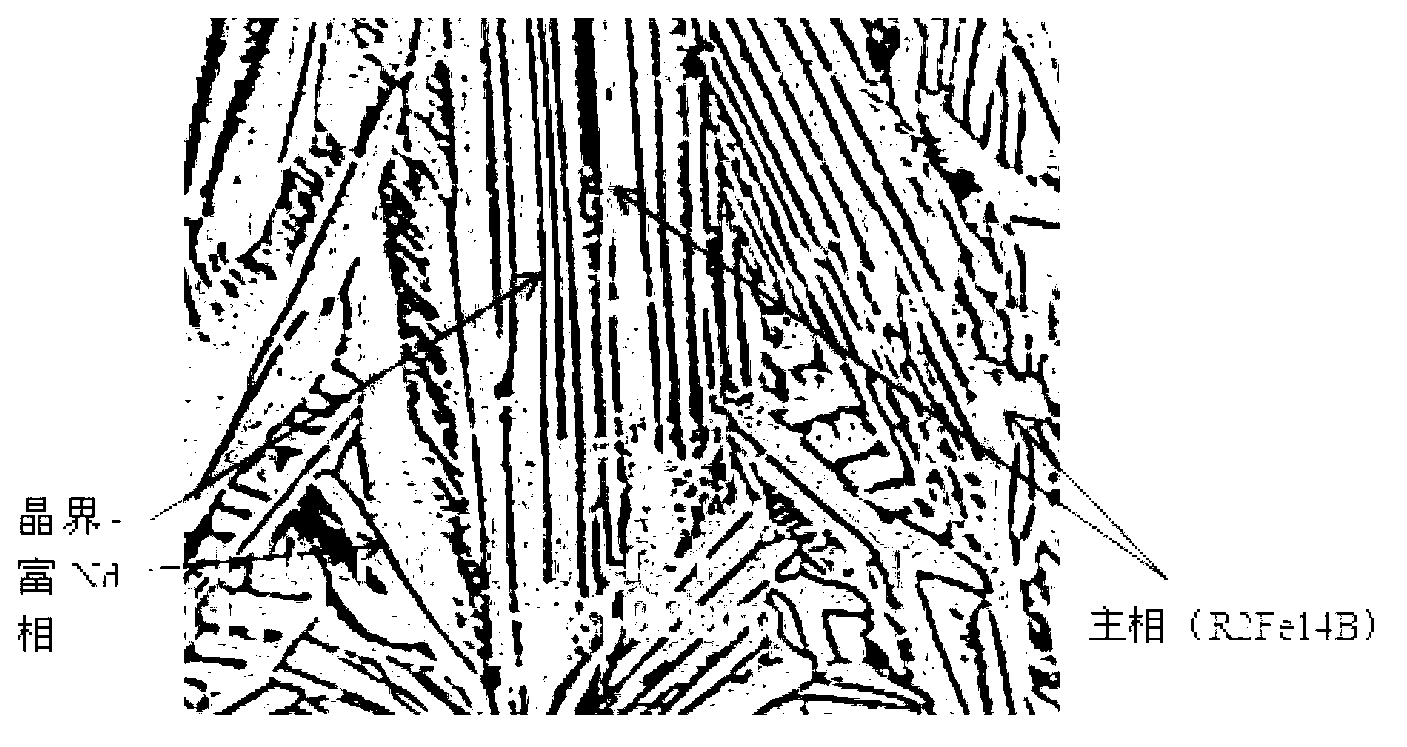

[0035] 2) Batching: Batching is carried out in proportion, and the proportion of ingredients can be expressed as R in weight percentage x T y B z Fe (100-x-y-z) , wherein R represents at least one of the rare earth elements including Sc, Dy, Tb, Ho, Gd and Y, and x represents the weight percentage of R, specifically 27wt%<x≤31wt%, preferably 28wt%<x ≤30.5wt%, more preferably 29wt%<x≤30wt%; if the weight percentage of R is too high, it is not conducive to improving the remanence of the magnet, and if it is too low, it needs to increase the sintering temperature, resulting in the increase of infiltrated elements into the main phase, causing remanenc...

Embodiment 1

[0051] Adopt formula weight percentage as R x T y B z Fe (100-x-y-z) formula, where x=29.5%, z=0.95%, grain boundary infiltration is carried out between smelting and coarse crushing, the infiltration element is Dy, and the infiltration weight percentage is 0.7%.

[0052] First select raw materials with a purity greater than 99wt%, and perform shot blasting for 10 to 60 minutes, according to the weight percentage of the formula (Nd+Pr) 29.5 (Co 0.4 Cu 0.1 Ga 0.1 Al 0.1 Zr 0.12 )B 0.95 Fe 68.73Ingredients, the prepared raw materials are melted in the vacuum strip billet continuous casting furnace. When the temperature of the alloy melt reaches 1470°C, the scale casting is carried out at the linear speed of the rollers at 1m / s per second. After the casting is completed, fill in The argon gas of about 80 kPa is forced to cool for 60-180 minutes, and the scales are continuously turned during the cooling process to obtain master alloy scales of rare earth permanent magnet ...

Embodiment 2

[0064] Adopt formula weight percentage as R x T y B z Fe (100-x-y-z) The formula, in which the rare earth elements represented by R do not add heavy rare earth elements Dy and Tb, x=30.5%, z=0.95%, infiltrate the grain boundary elements in the rare earth permanent magnet material master alloy scales after smelting, and the infiltrated elements are Al, the infiltration weight percentage is 0.18%.

[0065] First provide raw materials with a purity greater than 99wt%, and perform shot blasting treatment for 10-60 minutes, according to the weight percentage of the formula (Nd+Pr) 30.5 (Co 0.4 Cu 0.1 Ga 0.1 Zr 0.12 )B 0.95 Fe 67.83 Ingredients, the prepared raw materials are melted in the vacuum strip billet continuous casting furnace. When the temperature of the alloy melt reaches 1470°C, the scale casting is carried out at the linear speed of the rollers at 1m / s per second. After the casting is completed, fill in The argon gas of about 80 kPa is forced to cool for 60-18...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com