Annular positive electrode

A front electrode, ring-shaped technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of narrowing of the sintering window, increase in the proportion of low-power cells, loss, etc., to increase effective conduction, reduce power consumption, and reduce usage. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

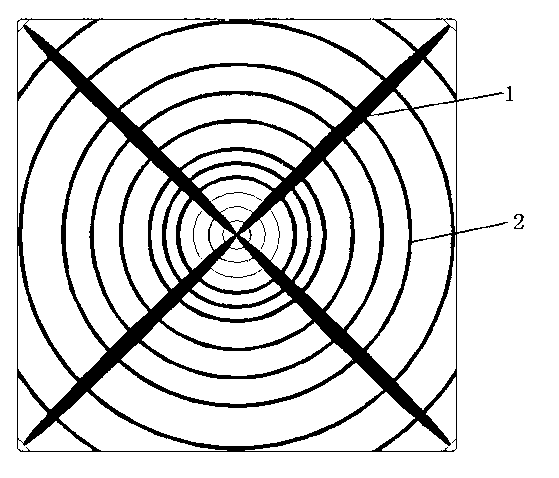

[0015] Such as figure 1 The front electrode of a solar cell shown includes: a main grid 1 and a thin grid 2; the thin grid 2 is a group of concentric rings centered on the center of the silicon wafer; the main grid 1 is a needle with a wide middle and two pointed ends Leaf shape; the main grid 1 divides the fine grid 2 into four equal parts. The rings in the thin grid 2 are from the inside to the outside, and the width of each ring gradually increases from small to small; the spacing between the rings in the thin grid 2 is dense in the center and sparse at the edges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com