Photovoltaic solar cell and method for producing a photovoltaic solar cell

A solar cell and photovoltaic technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as expensive processes and high costs, and achieve the effect of simplifying costs and manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

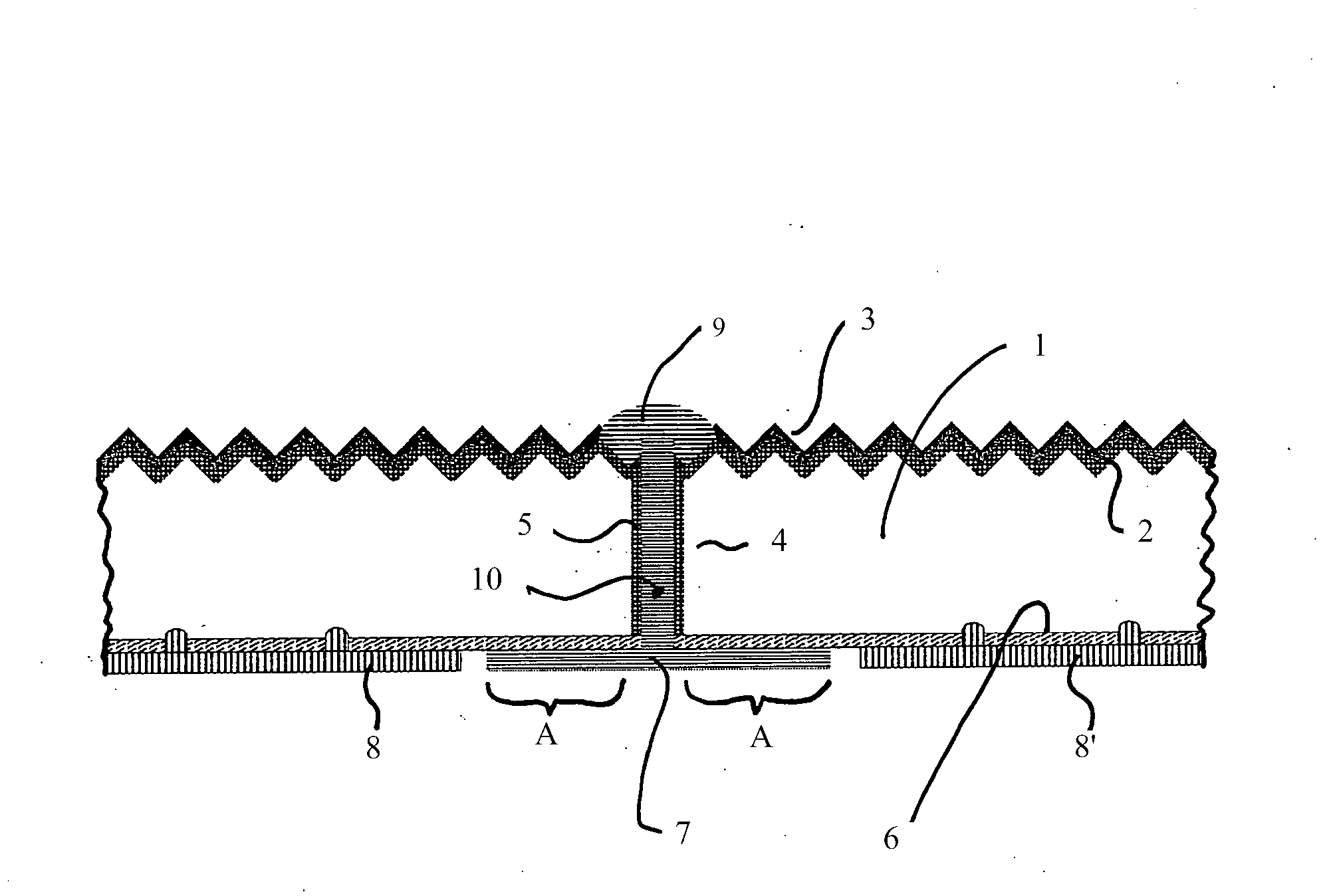

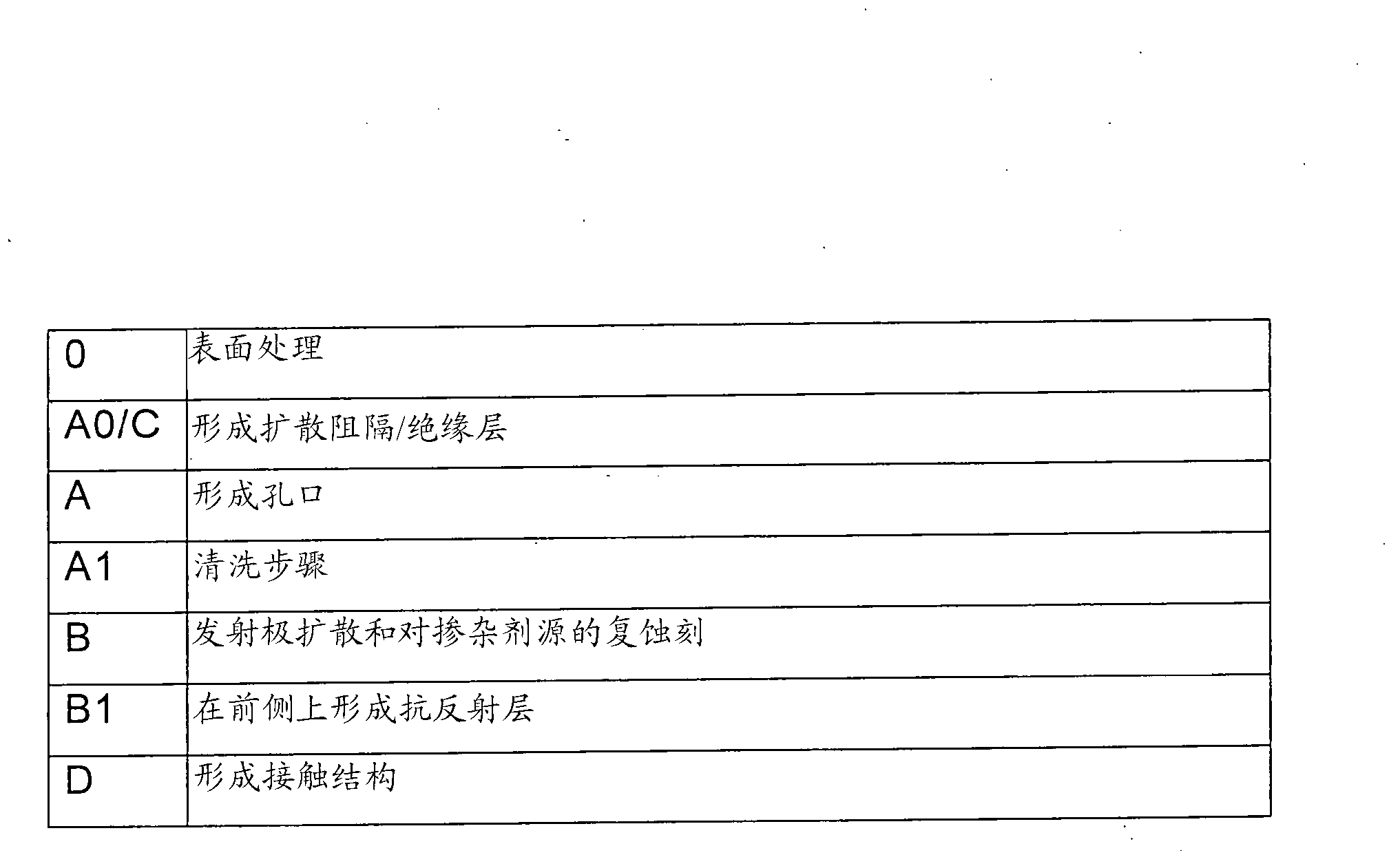

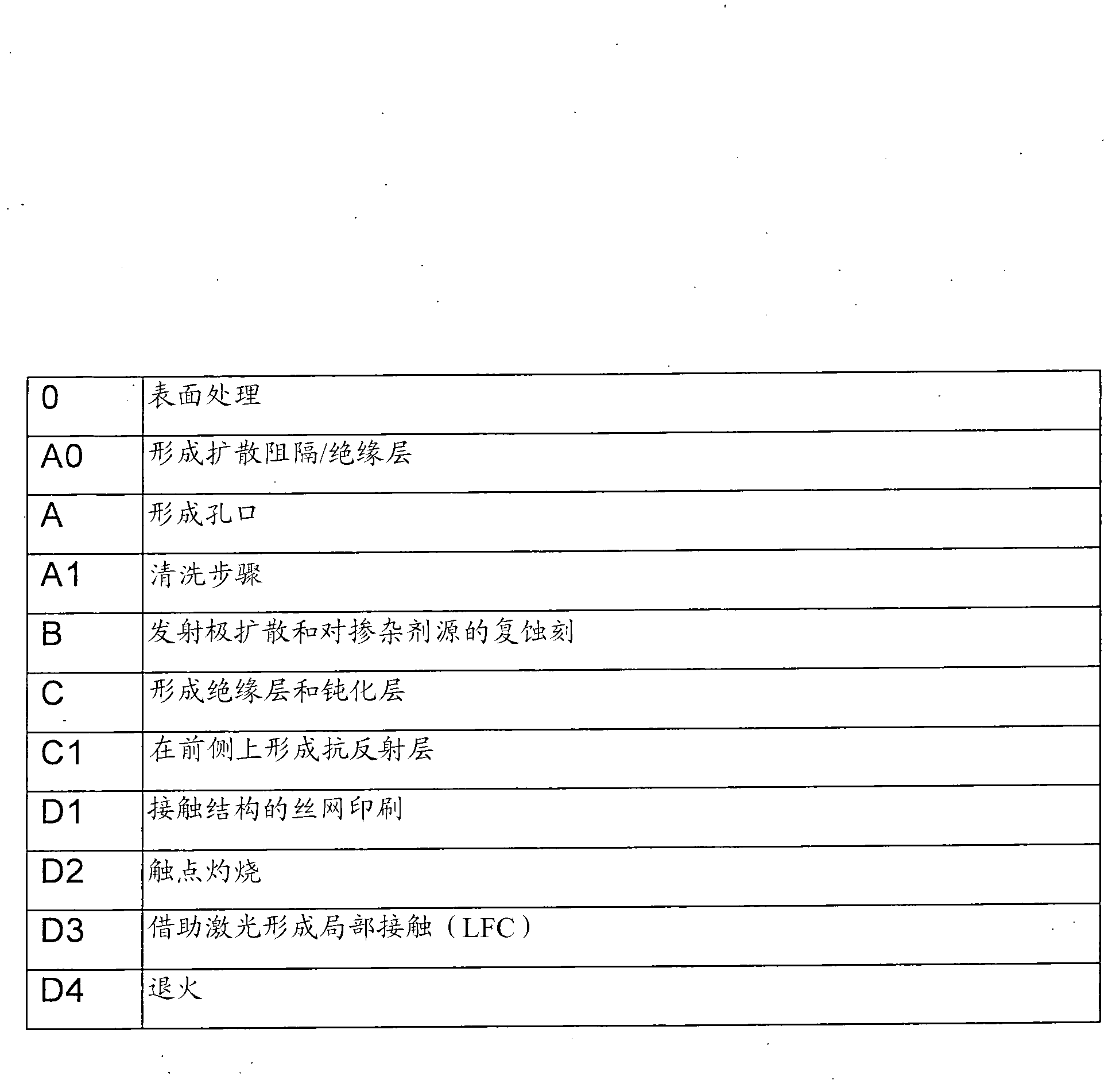

[0072] exist figure 1 The embodiment of the solar cell according to the invention shown in the following by means of image 3 Manufactured by the process described in .

[0073] exist figure 1 The solar cell according to the invention in the present invention comprises a P-doped semiconductor substrate 1 formed as a monocrystalline silicon wafer or a polycrystalline silicon wafer with a base resistance of 0.1 ohm-cm to 10 ohm-cm. exist figure 1 The front side emitter region 2 is formed on the front side shown in the upper middle. The front side has a texture to increase the light coupling, and in order to increase the light coupling, an antireflection layer 3 in the form of a silicon nitride layer with a thickness of approximately 70 nm is additionally arranged on the front side of the semiconductor substrate 1 .

[0074] figure 1 Only a part of a solar cell according to the invention with only one opening 4 is shown. The solar cell extends left and right in a mirror ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com