Freeze-dried gastrodia elata chewable tablet manufacturing method

A manufacturing method and technology of chewable tablets, which are applied in the field of freeze-dried gastrodia elata chewable tablets, can solve the problems of poor efficacy, less active ingredients of gastrodia elata, and large loss of active ingredients of gastrodia elata, and achieve the effect of large contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

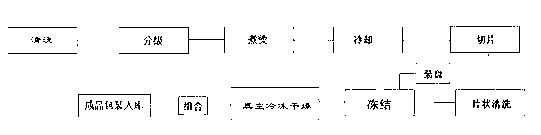

Image

Examples

Embodiment 1

[0025] A method for manufacturing freeze-dried gastrodia elata chewable tablets, comprising a cleaning step and a grading step, characterized in that it also includes the following steps:

[0026] Boiling: Boil the Gastrodia elata that has been cleaned and graded successively to passivate the active enzymes in Gastrodia elata. The boiling time is 10 minutes to prevent the loss of its active ingredients;

[0027] Cooling: put the boiled Gastrodia elata into sterile water for cooling, the cooling time is 3 hours, to ensure that the central temperature of Gastrodia elata is reduced to 18 degrees;

[0028] Slicing: Slicing the cooled Gastrodia elata, the slice thickness is 6mm;

[0029] Sheet cleaning: Clean the surface of the sliced Gastrodia elata slices, wash off the sticky matter on the surface, clean with sterile citric acid water, and protect the color;

[0030] Freezing: put the Gastrodia elata slices after cleaning in flakes into a cold storage below minus 35 degrees fo...

Embodiment 2

[0034] A method for manufacturing freeze-dried gastrodia elata chewable tablets, comprising a cleaning step and a grading step, characterized in that it also includes the following steps:

[0035] Boiling: Boil the Gastrodia elata that has been cleaned and graded successively to passivate the active enzymes in Gastrodia elata. The boiling time is 15 minutes to prevent the loss of its active ingredients;

[0036] Cooling: put the boiled Gastrodia elata into sterile water for cooling, the cooling time is 4 hours, to ensure that the central temperature of Gastrodia elata is reduced to 20 degrees;

[0037] Slicing: Slicing the cooled Gastrodia elata, the slice thickness is 8mm;

[0038] Sheet cleaning: Clean the surface of the sliced Gastrodia elata slices, wash off the sticky matter on the surface, clean with sterile citric acid water, and protect the color;

[0039] Freezing: put the Gastrodia elata slices after cleaning in flakes into a cold storage below minus 35 degrees fo...

Embodiment 3

[0045] The difference with embodiment 2 is:

[0046] A method for manufacturing freeze-dried gastrodia elata chewable tablets, comprising a cleaning step and a grading step, characterized in that it also includes the following steps:

[0047] Boiling: Boil the Gastrodia elata that has been cleaned and graded successively to passivate the active enzymes in Gastrodia elata. The boiling time is 20 minutes to prevent the loss of its active ingredients;

[0048] Cooling: put the boiled Gastrodia elata into sterile water for cooling, the cooling time is 5 hours, to ensure that the central temperature of Gastrodia elata is reduced to 24 degrees;

[0049] Slicing: Slicing the cooled Gastrodia elata with a thickness of 10mm;

[0050] Sheet cleaning: Clean the surface of the sliced Gastrodia elata slices, wash off the sticky matter on the surface, clean with sterile citric acid water, and protect the color;

[0051] Freezing: put the Gastrodia elata slices after cleaning in flakes int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com