Method for extracting phenylethanoid glycoside and flavonoid C-glycoside from corallodiscus flabellata

A technology of flavonoid carbon glycosides and phenethyl alcohol glycosides is applied in the directions of pharmaceutical formulations, non-central analgesics, medical preparations containing active ingredients, etc., to achieve the effects of simple method, easy operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

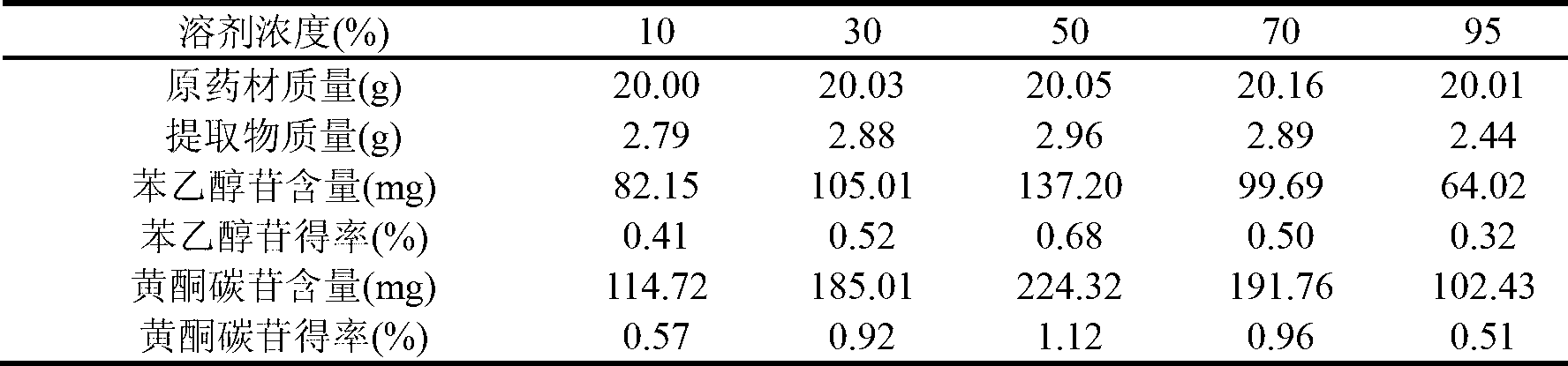

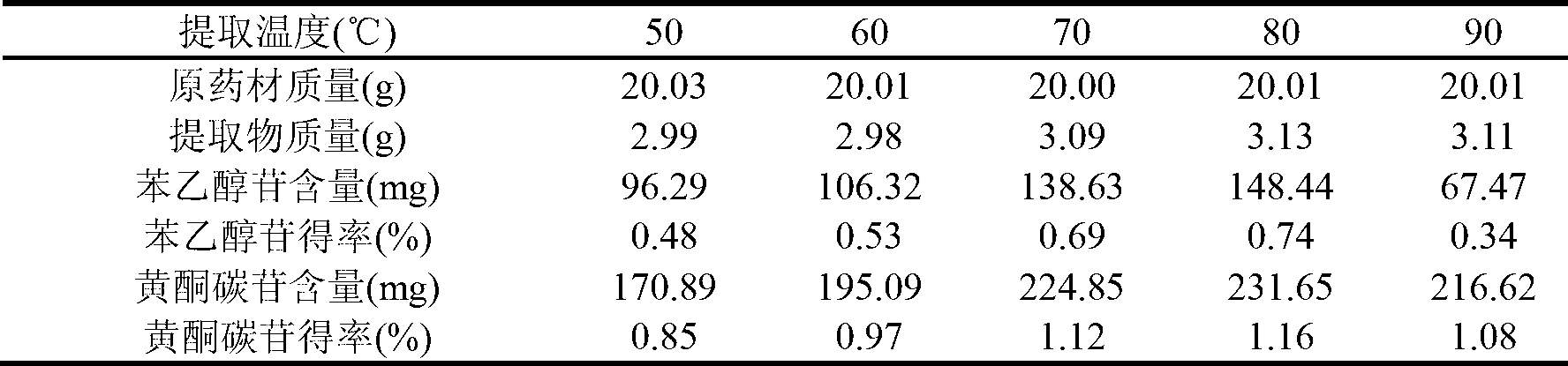

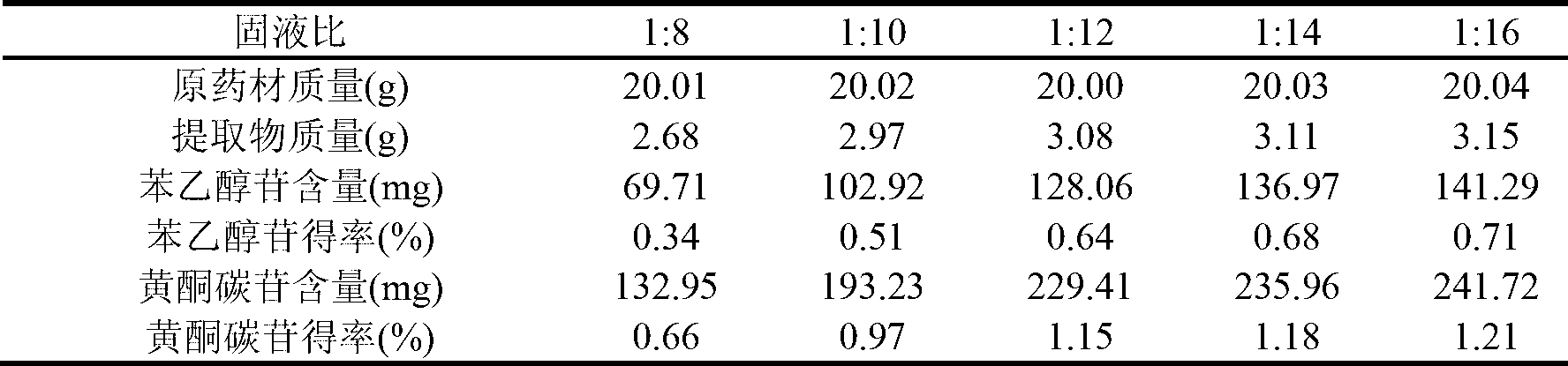

Method used

Image

Examples

Embodiment 1

[0010] Take Lithophora medicinal material, add ethanol with a mass concentration of 50%, the weight-to-volume ratio of medicinal material and ethanol is 1:12, reflux extraction at 80°C for 2.5 hours each time, filter, and recover the filtrate under reduced pressure Solvent, vacuum-dried to obtain extract, standby, get HPD-100 macroporous adsorption resin and carry out pretreatment, pretreatment method is, the mass concentration of HPD-100 macroporous adsorption resin is that the mass concentration of 0.5BV is 95% ethanol soaking 24h (BV is 1 resin bed volume), with 2BV of ethanol with a mass concentration of 95% at 2BV·h -1 The flow rate is passed through the resin column, and the resin is soaked for 4h, and the mass concentration is 95% ethanol 2BV·h -1 Wash the resin at a flow rate of 5% hydrochloric acid solution with a mass concentration of 2BV at 5BV·h -1 The flow rate passes through the resin layer, and the resin is soaked for 3 hours, and then washed with water to neut...

Embodiment 2

[0012] Take the medicinal material of Lithium gallbladder, add ethanol with a mass concentration of 10%, the weight volume ratio of the medicinal material of Lithium gallbladder and ethanol is 1:8, reflux extraction once at 50°C, each extraction time is 1.5h, filter, and the filtrate is decompressed Reclaim solvent, vacuum-dry to get extract, standby, get HPD-100 macroporous adsorption resin and carry out pretreatment, pretreatment method is, the mass concentration of HPD-100 macroporous adsorption resin is that the mass concentration of 0.5BV is 95% ethanol soaking 24h (BV is 1 resin bed volume), with 2BV of ethanol with a mass concentration of 95% at 2BV·h -1 The flow rate is passed through the resin column, and the resin is soaked for 4h, and the mass concentration is 95% ethanol 2BV·h -1 Wash the resin at a flow rate of 2BV until the effluent has no white turbidity when adding water, and then wash with water at the same flow rate until there is no alcohol smell; use 5% hyd...

Embodiment 3

[0014] Take the herba olidocarpi, add ethanol with a mass concentration of 95%, the weight-to-volume ratio of the herb and ethanol is 1:16, reflux extraction at 90°C for 3.5 hours each time, filter, and recover the filtrate under reduced pressure Solvent, vacuum-dried to obtain extract, standby, get HPD-100 macroporous adsorption resin and carry out pretreatment, pretreatment method is, the mass concentration of HPD-100 macroporous adsorption resin is that the mass concentration of 0.5BV is 95% ethanol soaking 24h (BV is 1 resin bed volume), with 2BV of ethanol with a mass concentration of 95% at 2BV·h -1 The flow rate is passed through the resin column, and the resin is soaked for 5h, and the mass concentration is 95% ethanol 2BV·h -1 Wash the resin at a flow rate of 2BV until the effluent has no white turbidity when adding water, then wash with water at the same flow rate until there is no alcohol smell; use 5% hydrochloric acid solution with a mass concentration of 2BV to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com