Preparation method of Fe3O4@MnO2/active carbon magnetic compound adsorption material

A technology of composite adsorption material and activated carbon, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of limited application, difficult separation, small adsorption capacity, etc., and achieve cheap synthetic materials and synthetic methods Simple, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

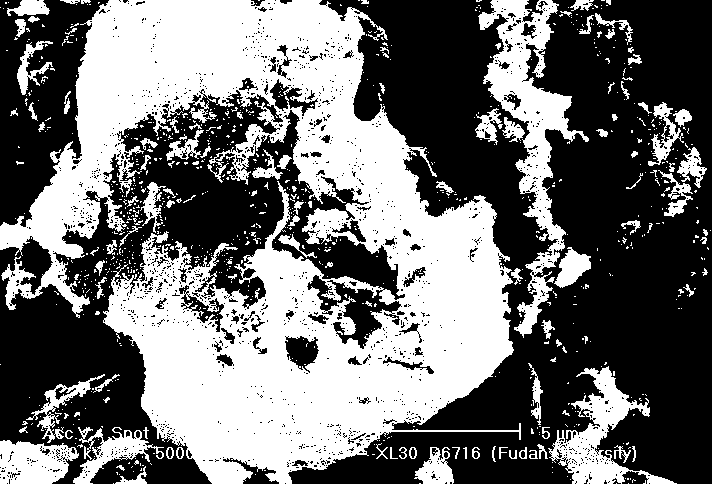

Image

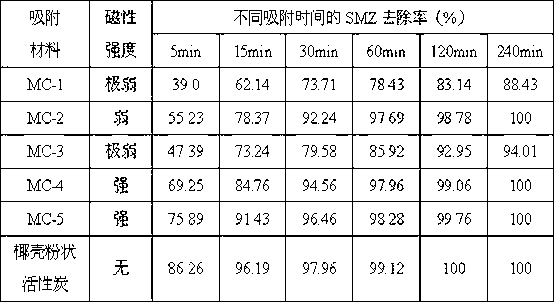

Examples

Embodiment 1

[0018] (1) Put 0.7g ferrous sulfate (FeSO 4 ·7H 2 O) dissolved in 50mL deionized water (filled with high-purity N 2 To remove dissolved oxygen), add 0.5g coconut shell powdered activated carbon, stir vigorously at 25°C for 30min, then quickly add 1mL of 5M ammonia water, stir vigorously for 5min to obtain suspension A;

[0019] (2) According to Fe 2+ / OH - / Mn 7+ Quickly add 0.25M potassium permanganate solution dropwise into the suspension A with a molar ratio of 4.5:9:0.5, and stir vigorously to make it evenly mixed, and age it hydrothermally at 25°C for 12 hours to obtain the brown-black product B ;

[0020] (3) Wash the obtained brown-black product B repeatedly with a large amount of deionized water, and separate it with a strong magnet;

[0021] (4) Vacuum-dry the brown-black product after washing and separation at 60°C to constant weight to obtain the desired product.

Embodiment 2

[0023] (1) Put 0.7g ferrous sulfate (FeSO 4 ·7H 2 O) dissolved in 50mL deionized water (filled with high-purity N 2 To remove dissolved oxygen), add 0.5g coconut shell powdered activated carbon, stir vigorously at 25°C for 30min, then quickly add 1mL of 5M ammonia water, stir vigorously for 5min to obtain suspension A;

[0024] (2) According to Fe 2+ / OH - / Mn 7+ Quickly add 0.25M potassium permanganate solution dropwise into the suspension A at a molar ratio of 4.5:9:0.75, and stir vigorously to make it evenly mixed, and age it hydrothermally at 25°C for 12 hours to obtain the brown-black product B ;

[0025] Steps (3) and (4) in Example 1 were repeated.

Embodiment 3

[0027] (1) Put 0.7g ferrous sulfate (FeSO 4 ·7H 2 O) dissolved in 50mL deionized water (filled with high-purity N 2 To remove dissolved oxygen), add 0.5g coconut shell powdered activated carbon, stir vigorously at 25°C for 30min, then quickly add 1mL of 5M ammonia water, stir vigorously for 5min to obtain suspension A;

[0028] (2) According to Fe 2+ / OH - / Mn 7+ Quickly add 0.25M potassium permanganate solution dropwise into the suspension A at a molar ratio of 4.5:9:1, and stir vigorously to make it evenly mixed, and age it hydrothermally at 25°C for 12 hours to obtain the brown-black product B ;

[0029] Steps (3) and (4) in Example 1 were repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com