One-dimensional nanometer titania photocatalyst with mica serving as support and preparation method thereof

A nano-titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor dispersibility, easy dispersion, difficult recovery, etc. Surface area, the effect of reducing the agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

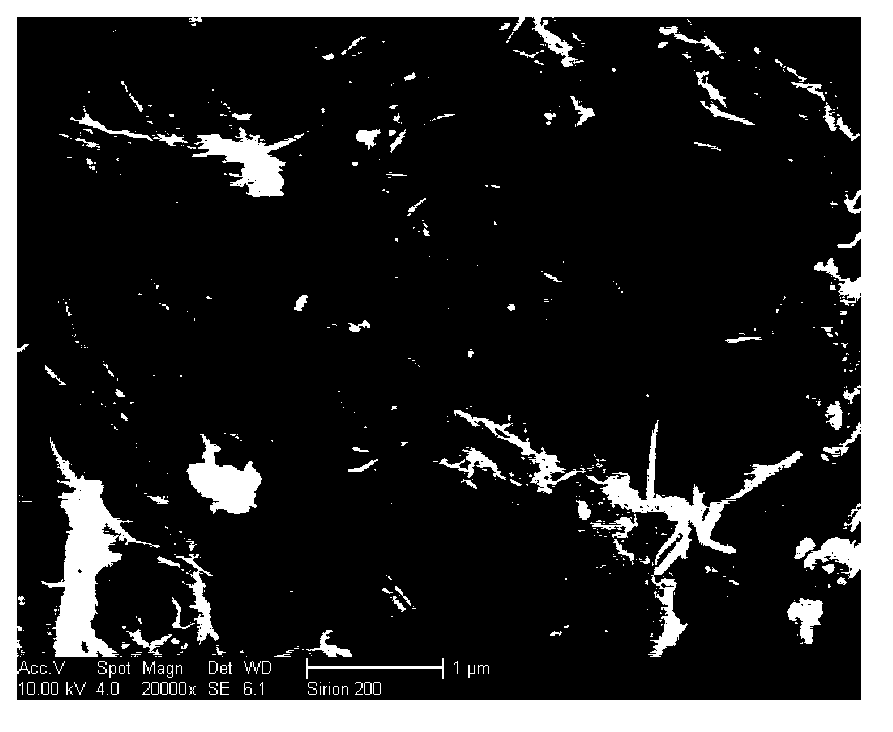

Image

Examples

Embodiment 1

[0029] Weigh 15g of 300-100mesh muscovite into a 500ml beaker, add 500ml of distilled water to prepare a suspension, stir and heat to 85°C, add 50ml of HCl solution with a mass concentration of 35% and continue stirring for 30min, wait until the temperature drops to 60°C At ℃, wash repeatedly with distilled water and absolute ethanol, and filter with suction until there is no Cl in the filtrate. - (using 0.1mol·L -1 AgNO 3 solution test), vacuum-dried to obtain pretreated mica for subsequent use.

[0030] Weigh 6g of pretreated mica in a beaker, add 300ml of distilled water to prepare a suspension, heat and stir in a water bath to 80°C, adjust the pH value to 2-2.5 with 1mol / L hydrochloric acid solution, and then quickly add 40g of urea (neutralization 0.1mol / L titanium tetrachloride solution (prepared under ice-water bath environment) dropwise at the same time of 250ml, the rate of addition is controlled at 1ml / min, after the titanium tetrachloride solution is all dripped, ...

Embodiment 2

[0033] Weigh 15g of 300-100mesh muscovite into a 500ml beaker, add 500ml of distilled water to prepare a suspension, stir and heat to 85°C, add 50ml of HCl solution with a mass concentration of 35% and continue stirring for 30min, wait until the temperature drops to 60°C At ℃, wash repeatedly with distilled water and absolute ethanol, and filter with suction until there is no Cl in the filtrate. - (using 0.1mol·L -1 AgNO 3 solution test), vacuum-dried to obtain pretreated mica for subsequent use.

[0034] Weigh 6g of pretreated mica in a beaker, add 300ml of distilled water to prepare a suspension, heat and stir in a water bath to 80°C, adjust the pH value to 2-2.5 with 1mol / L hydrochloric acid solution, and then quickly add 40g of urea (neutralization 0.1mol / L titanium tetrachloride solution (prepared under ice-water bath environment) dropwise at the same time of 250ml, the rate of addition is controlled at 1ml / min, after the titanium tetrachloride solution is all dripped, ...

Embodiment 3

[0037] Weigh 15g of 300-100mesh muscovite into a 500ml beaker, add 500ml of distilled water to prepare a suspension, stir and heat to 85°C, add 50ml of HCl solution with a mass concentration of 35% and continue stirring for 30min, wait until the temperature drops to 60°C At ℃, wash repeatedly with distilled water and absolute ethanol, and filter with suction until there is no Cl in the filtrate. - (using 0.1mol·L -1 AgNO 3 solution test), vacuum-dried to obtain pretreated mica for subsequent use.

[0038] Weigh 6g of pretreated mica in a beaker, add 300ml of distilled water to prepare a suspension, heat and stir in a water bath to 80°C, adjust the pH value to 2-2.5 with 1mol / L hydrochloric acid solution, and then quickly add 40g of urea (neutralization 0.1mol / L titanium tetrachloride solution (prepared under ice-water bath environment) dropwise at the same time of 250ml, the rate of addition is controlled at 1ml / min, after the titanium tetrachloride solution is all dripped, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sheet thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com