TiO2 nano material, and preparation method and application thereof

A technology of nanomaterials and mixed materials, applied in the field of its preparation, TiO2 nanomaterials, can solve the problems of decreased dispersibility, loss of economic benefits and performance, complicated synthesis steps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Add 4 mL of concentrated hydrochloric acid solution into 7 mL of deionized water, stir evenly to form a dilute hydrochloric acid solution, and add 1 mL of 3mol / L TiCl drop by drop while stirring 4 Solution, continue to stir evenly, obtain mixed material, in described mixed material, hydrochloric acid (HCl) concentration is 4.02mol / L, TiCl 4 The concentration is 0.25mol / L;

[0055] (2) Add 0.1mL of 30wt% commercially available hydrogen peroxide drop by drop to the mixed material in step (1) while stirring, and continue to stir evenly to obtain an orange-red precursor;

[0056] (3) Move the precursor in step (2) to a 100mL polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 180°C for 8 hours to obtain a white emulsion;

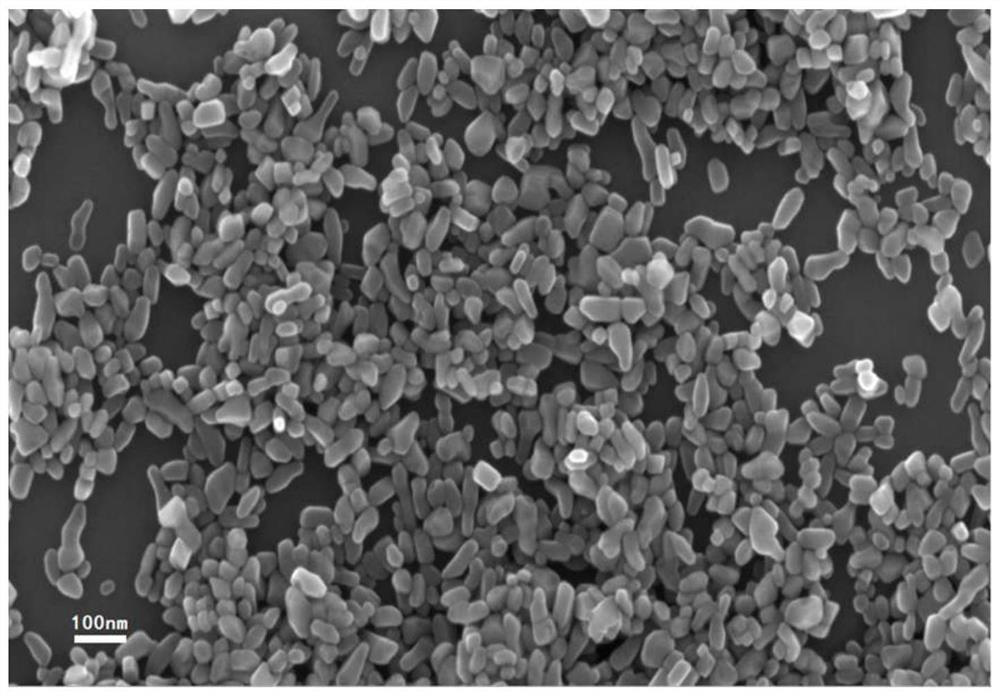

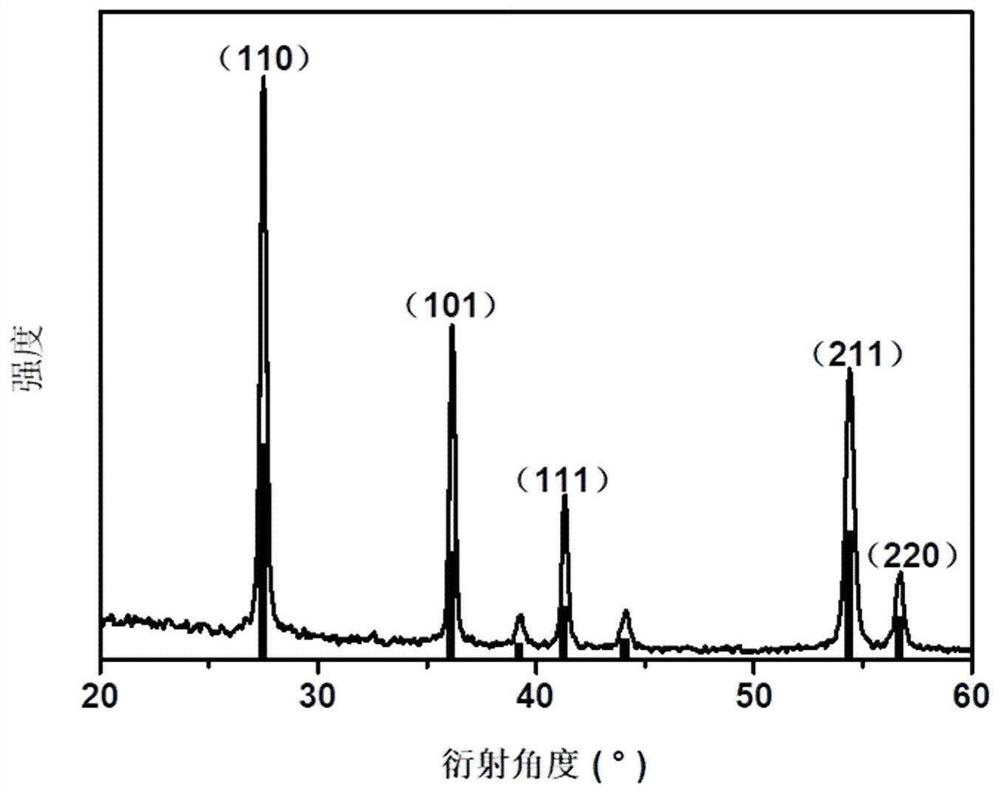

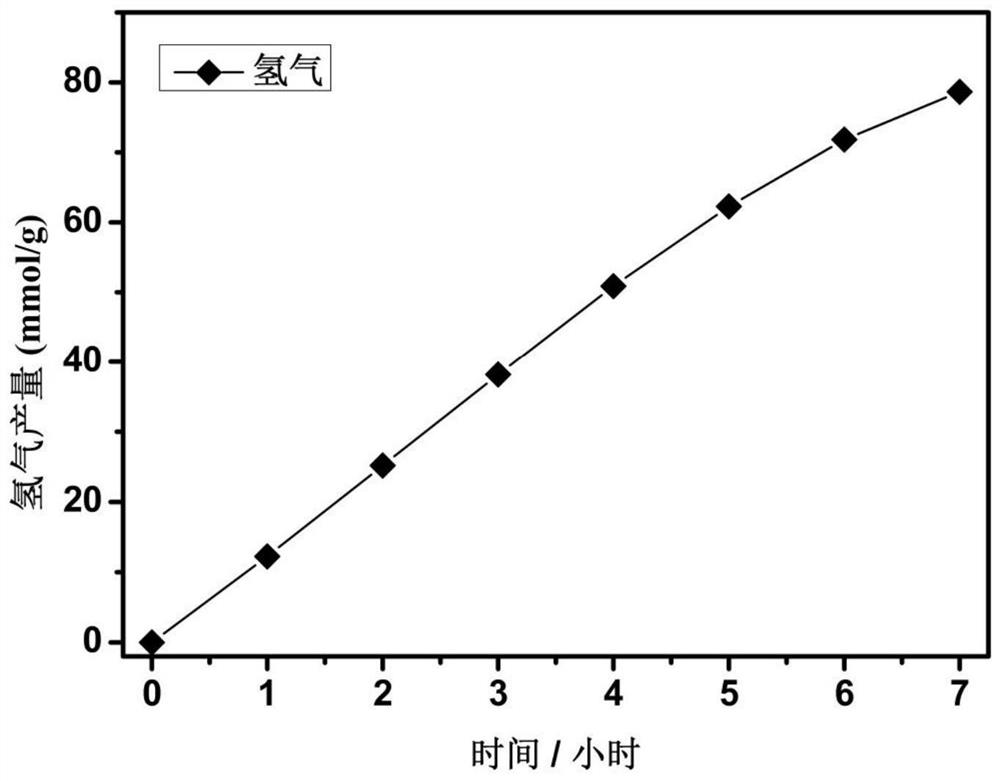

[0057] (4) After the reaction is completed, the white emulsion obtained in step (3) is washed 3 times with ethanol, then washed 3 times with water, and dried at 80° C. to obtain TiO 2 nanomaterials, the TiO 2 The nanomaterial is...

Embodiment 2

[0062] (1) Add 4mL concentrated hydrochloric acid solution into 19mL deionized water, stir evenly to form a dilute hydrochloric acid solution, add 1mL 3mol / L TiCl dropwise while stirring 4 solution, continue to stir evenly to obtain a mixed material, and in the mixed material, the concentration of hydrochloric acid is 2.0mol / L, TiCl 4 The concentration is 0.13mol / L;

[0063] (2) Add 0.05mL 30wt% commercially available hydrogen peroxide dropwise to the mixed material in step (1) while stirring, and continue to stir evenly to obtain an orange-red precursor;

[0064] (3) Move the precursor in step (2) to a 100mL polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 220°C for 8 hours to obtain a white emulsion;

[0065] (4) After the reaction is completed, the white emulsion obtained in step (3) is washed 3 times with ethanol, then washed 3 times with water, and dried at 80° C. to obtain TiO 2 nanomaterials, the TiO 2 The nanomaterial is rutile type, and has r...

Embodiment 3

[0067] (1) Add 5mL concentrated hydrochloric acid solution into 6mL deionized water, stir evenly to form a dilute hydrochloric acid solution, add 1mL 3mol / L TiCl drop by drop while stirring 4 Solution, continue to stir evenly, obtain mixed material, in described mixed material, hydrochloric acid concentration is 5.03mol / L, TiCl 4 The concentration is 0.25mol / L;

[0068] (2) Add 0.1mL of 30wt% commercially available hydrogen peroxide drop by drop to the mixed material in step (1) while stirring, and continue to stir evenly to obtain an orange-red precursor;

[0069] (3) Move the precursor in step (2) to a 100mL polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at 180°C for 12 hours to obtain a white emulsion;

[0070] (4) After the reaction is completed, the white emulsion obtained in step (3) is washed 3 times with ethanol, then washed 3 times with water, and dried at 80° C. to obtain TiO 2 nanomaterials, the TiO 2 The nanomaterial is of the rutile type. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com