Preparation of highly active cqds/bivo by combustion of a carbon fiber-supported liquid film 4 Method for Composite Nano Photocatalytic Materials

A technology supporting liquid membranes and catalytic materials, applied in the field of environmental pollution control, to achieve the effects of good repeatability, small crystal particle size, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

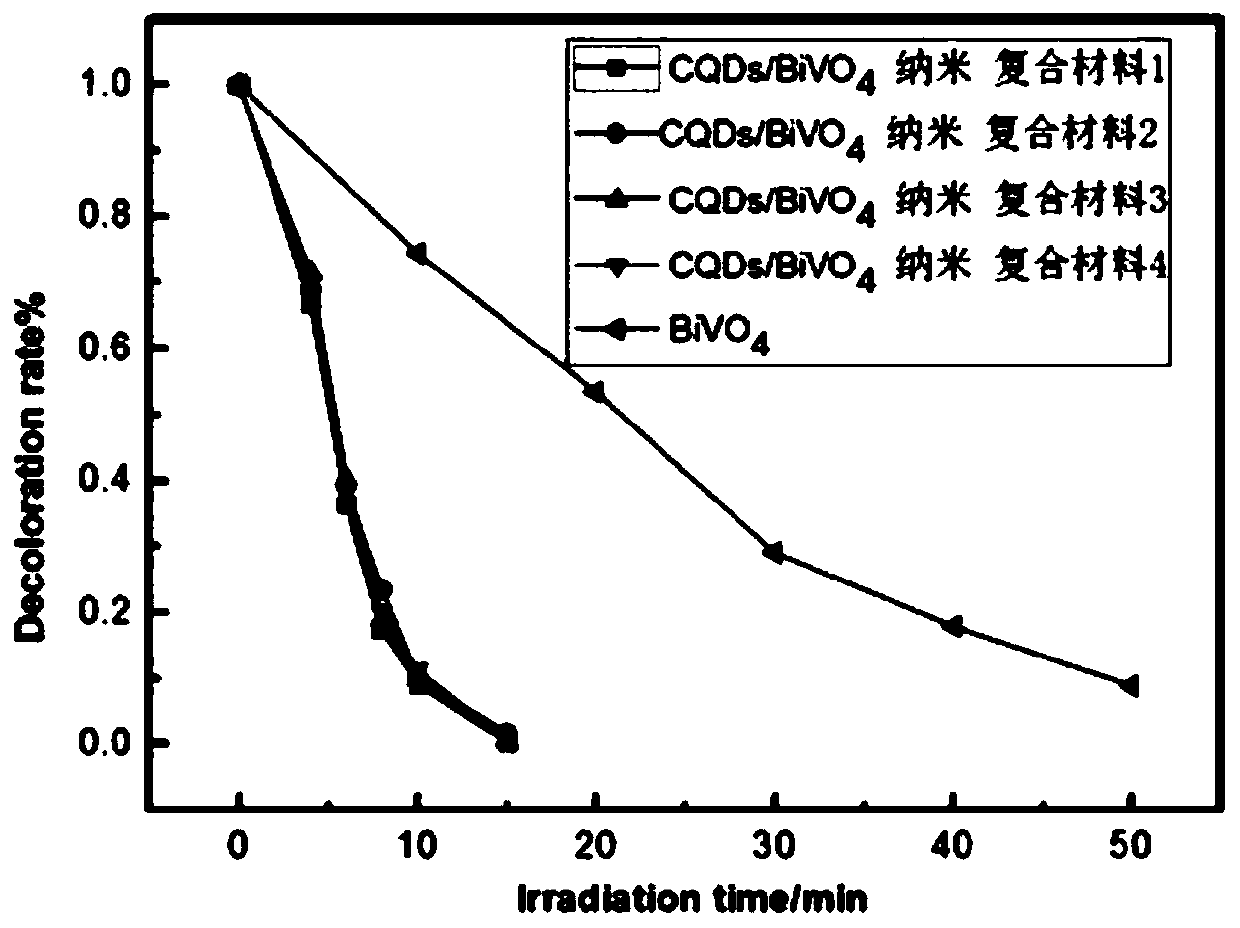

example 1

[0015] Example 1: (1) Carbon fiber modification: Cut the non-adhesive carbon fiber into 10cm long, use acetone, ethanol and deionized water to clean it ultrasonically, then soak it in concentrated nitric acid for 72 hours, and then clean it ultrasonically with deionized water. Dry at 40°C; (2) BiVO 4 Preparation of reaction solution: Dissolve 0.01mol bismuth nitrate and ammonium metavanadate in 25mL deionized water at 80°C respectively, then add 0.02mol citric acid to the two solutions respectively, then mix the two reaction solutions, and then adjust the mixed solution with ammonia water The pH value is 6, then continuously stir and evaporate the reaction raw material solution at 80°C to the remaining 20mL, and impregnate 15g of modified carbon fibers into the reaction solution in equal volume; (3) place the carbon fiber with a layer of reaction solution liquid film in step (2) Calcined in a muffle furnace at 450 ° C for 1 h; (4) the BiVO obtained in step (3) 4 The carbon fi...

example 2

[0016] Example 2: (1) Carbon fiber modification: Cut the non-adhesive carbon fiber into 10 cm long, use acetone, ethanol and deionized water to clean it ultrasonically, then soak it in concentrated nitric acid for 48 hours, and then clean it ultrasonically with deionized water. Dry at 40°C; (2) BiVO 4 Preparation of reaction solution: Dissolve 0.01mol bismuth nitrate and ammonium metavanadate in 25mL deionized water at 80°C respectively, then add 0.02mol citric acid to the two solutions respectively, then mix the two reaction solutions, and then adjust the mixed solution with ammonia water The pH value is 6, then continue stirring and evaporating the reaction raw material solution at 80°C to the remaining 10mL, and impregnate 10g of modified carbon fibers in equal volumes in the reaction solution; (3) place the carbon fiber with a layer of reaction solution liquid film in step (2) Calcined in a muffle furnace at 400 ° C for 1 h; (4) the BiVO obtained in step (3) 4 The carbon ...

example 3

[0017] Example 3: (1) Carbon fiber modification: Cut the non-adhesive carbon fiber into 10 cm long, use acetone, ethanol and deionized water to clean it ultrasonically, then soak it in concentrated nitric acid for 48 hours, and then clean it ultrasonically with deionized water. Dry at 40°C; (2) BiVO 4 Preparation of reaction solution: Dissolve 0.01mol bismuth nitrate and ammonium metavanadate in 25mL ethylene glycol at 80°C respectively, then add 0.01mol urea to the two solutions respectively, then mix the two reaction solutions, and adjust the mixed solution with ammonia water The pH value is 6, then continue stirring and evaporating the reaction raw material solution at 80°C to the remaining 12mL, and impregnate 10g of modified carbon fibers into the reaction solution in equal volume; (3) place the carbon fiber with a layer of reaction solution liquid film in step (2) Calcined in a muffle furnace at 400 ° C for 1 h; (4) the BiVO obtained in step (3) 4 The carbon fiber was w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com