Device for preventing acrylate adhesive from gelating

A technology of acrylic ester and adhesive, which is applied to the device and coating of surface coating liquid, which can solve the problems of affecting the usage rate of glue and coating quality, and the effect is not obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

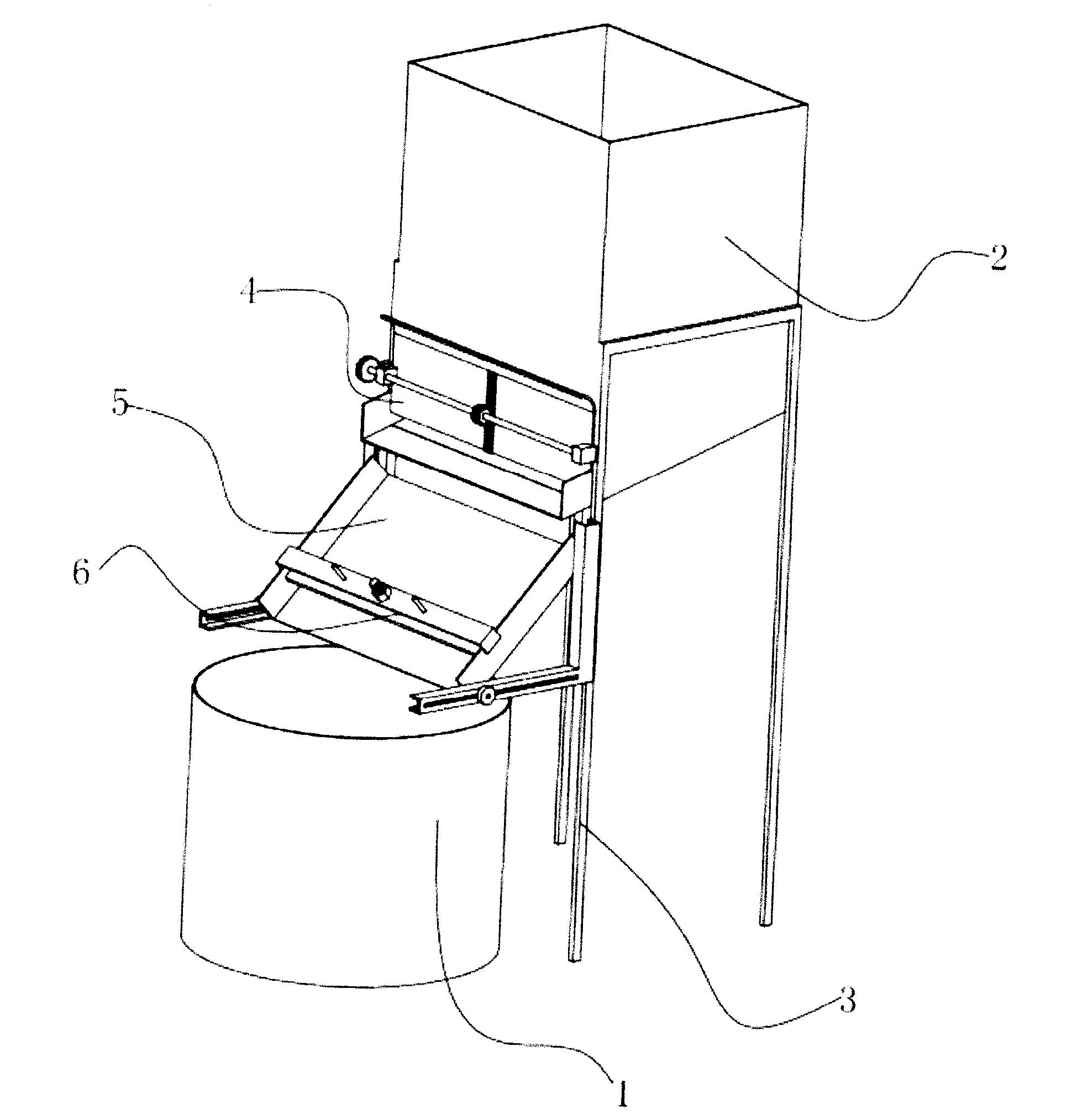

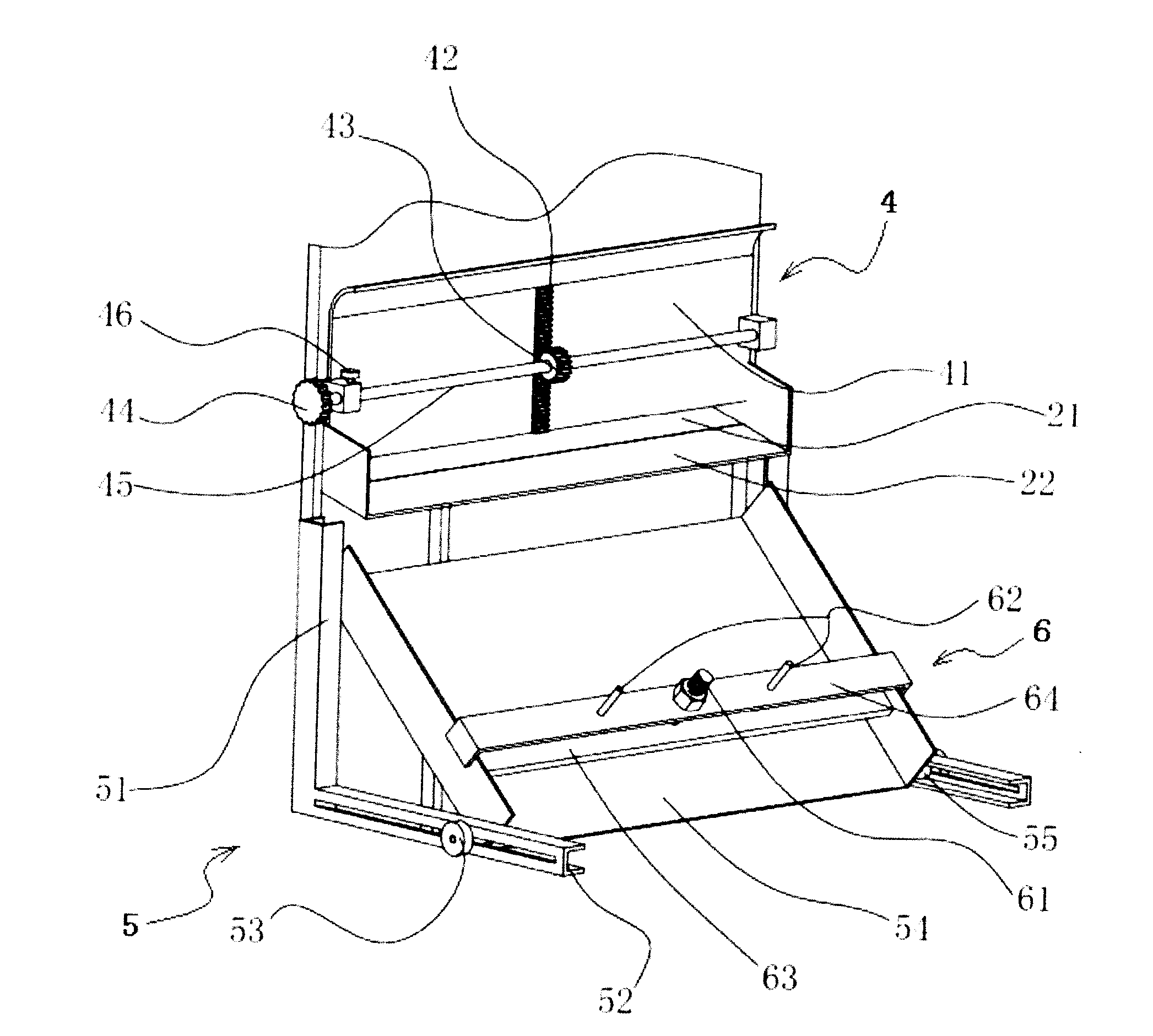

[0023] refer to figure 1 , figure 2 As shown, a device that can prevent acrylate adhesive from gelling includes a glue storage device 2, a glue output control part 4, a glue flow rate control part 5, and a high-voltage electric field processing part 6. The glue storage device 2 is supported by the feet 3, and one end of the bottom is provided with a glue outlet 21, and the bottom is inclined along the direction of the glue outlet, so that the glue can flow out of the glue storage device 2 smoothly.

[0024] The glue outlet 21 of the glue storage device 2 is provided with a glue quantity control unit 4, which is composed of a rubber baffle 41, an adjusting rod 45, and a fixing bolt 46. The rotation of the adjustment rod through the circular handle 44 can drive the gear 43 arranged on the adjustment rod to rotate, and the gear 43 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com