Preparation method of quartz ceramic crucible

A technology of quartz ceramics and crucibles, applied in crucible furnaces, glass manufacturing equipment, chemical instruments and methods, etc., can solve the problem of high impurity content of polycrystalline silicon ingots, and achieve the effect of simple and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 prepares quartz ceramic crucible

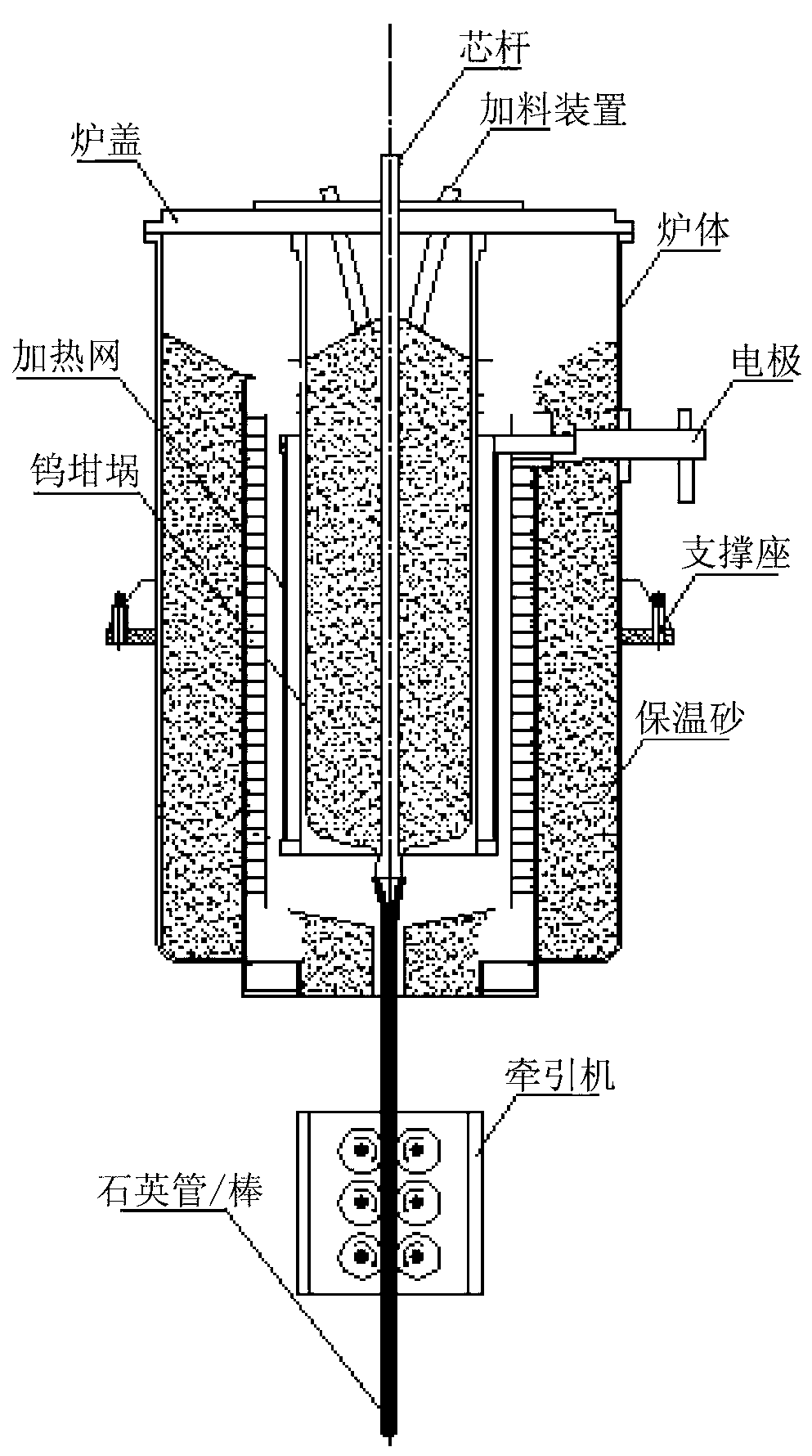

[0017] Even the furnace (such as figure 1 shown) is an existing device, which is fixed by a support base, which includes a furnace body and a furnace cover that cooperate with each other. A tungsten crucible (or molybdenum crucible) is arranged in the furnace body, and a connection electrode is arranged on the outside of the tungsten crucible (or molybdenum crucible). Heating net and heat preservation sand, the upper end of the tungsten crucible (or molybdenum crucible) is connected with a feeding device, and the lower end is connected with a forming device, which is controlled by a tractor.

[0018] The quartz sand whose diameter is less than 2mm and whose content of Fe, Na and K are all less than 5ppm is continuously added into the tungsten crucible (or molybdenum crucible) through the feeding device, heated to 1900~2400°C and maintained, so that the quartz sand Fully melt, and use high-purity hydrogen or nitrogen as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com