Curing method of copper sludge

A solidification method, copper sludge technology, applied in the field of energy chemistry, can solve the problems of occupying land resources, wasting useful value, etc., and achieve the effect of comprehensive utilization and considerable economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

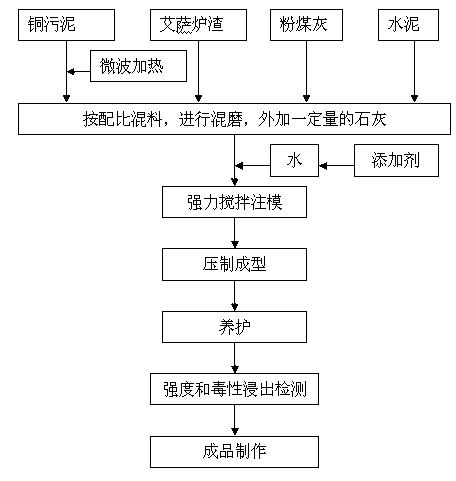

Image

Examples

Embodiment 1

[0024] Example 1: The solidification method of copper sludge is as follows:

[0025] (1) The copper sludge composition of a copper smelting plant used in this example is shown in Table 1, the Isa slag composition of a copper smelting plant is shown in Table 2, and the fly ash composition is shown in Table 3:

[0026] Table 1: Composition of copper sludge in a copper smelter

[0027] ingredients As S Zn Fe Sb Pb Bi Cu CD other % 9.44 4.65 2.08 1.93 0.64 0.22 0.05 0.02 - -

[0028] Table 2: Composition of Isa slag in a copper smelter

[0029] ingredients Cu S Fe CuO SiO 2 Pb Zn As Al 2 O 3 MgO % 9.47 4.17 35.36 2.56 24.18 0.45 1.93 0.09 3.90 1.40

[0030] Table 3: Fly Ash Composition

[0031] ingredients SiO 2 Al 2 O 3 Fe 2 O 3 CaO MgO loss % 59.47 27.98 6.33 4.11 0.98 3.70

[0032] (2) After the copper sludge was naturally air-dried ...

Embodiment 2

[0035] Example 2: The solidification method of copper sludge is as follows:

[0036] (1) The copper sludge of a certain copper smelting plant, the Isa slag of a certain copper smelting plant, and the fly ash components used in this example are the same as those of Example 1;

[0037] (2) After the copper sludge is naturally air-dried, pulverized and mixed, the sludge is subjected to microwave heating treatment at 600°C for 0.5h, and 20% copper sludge, 35% Isa slag, 20% Fly ash and ordinary Portland cement with a mass percentage of 25% are mixed, and the mixed grinding time is 25 minutes. During the mixed grinding process, 7% lime by weight of the mixture is added. After the mixed grinding, water and additives are added to the materials. The amount of cement and fly ash is 0.177% of the mass of cement and fly ash. Additives and water are added to the mixed and ground materials at the same time. The amount of additives added is 0.12% of the mass of the mixture, of which sodium...

Embodiment 3

[0040] Example 3: The solidification method of copper sludge is as follows:

[0041] (1) The copper sludge of a certain copper smelting plant, the Isa slag of a certain copper smelting plant, and the fly ash components used in this example are the same as those of Example 1;

[0042](2) After the copper sludge is naturally air-dried, pulverized and mixed, the sludge is subjected to microwave heating treatment at 400°C for 0.8h, and the copper sludge with a mass percentage of 30%, the Isa slag with a mass percentage of 20%, and the slag with a mass percentage of 35% Fly ash and ordinary Portland cement with a mass percentage of 15% were mixed and mixed and ground for 30 minutes. During the mixing and grinding process, 9% lime was added to the mixture. Water and additives were added to the material after mixing and grinding. The addition of water The amount is 0.2% of the mass of cement and fly ash, and the additive and water are added to the mixed and ground material at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com