Preparation method of biomass sandy soil improving agent

A sandy soil and improver technology, which is applied in the preparation of organic fertilizers, bio-organic part treatment, organic fertilizers, etc., can solve the problems of restricting the productivity level of planting industry and vegetation recovery ability, poor water holding capacity, and nutrient barrenness, etc., to achieve Significant improvement effect, high water storage function, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

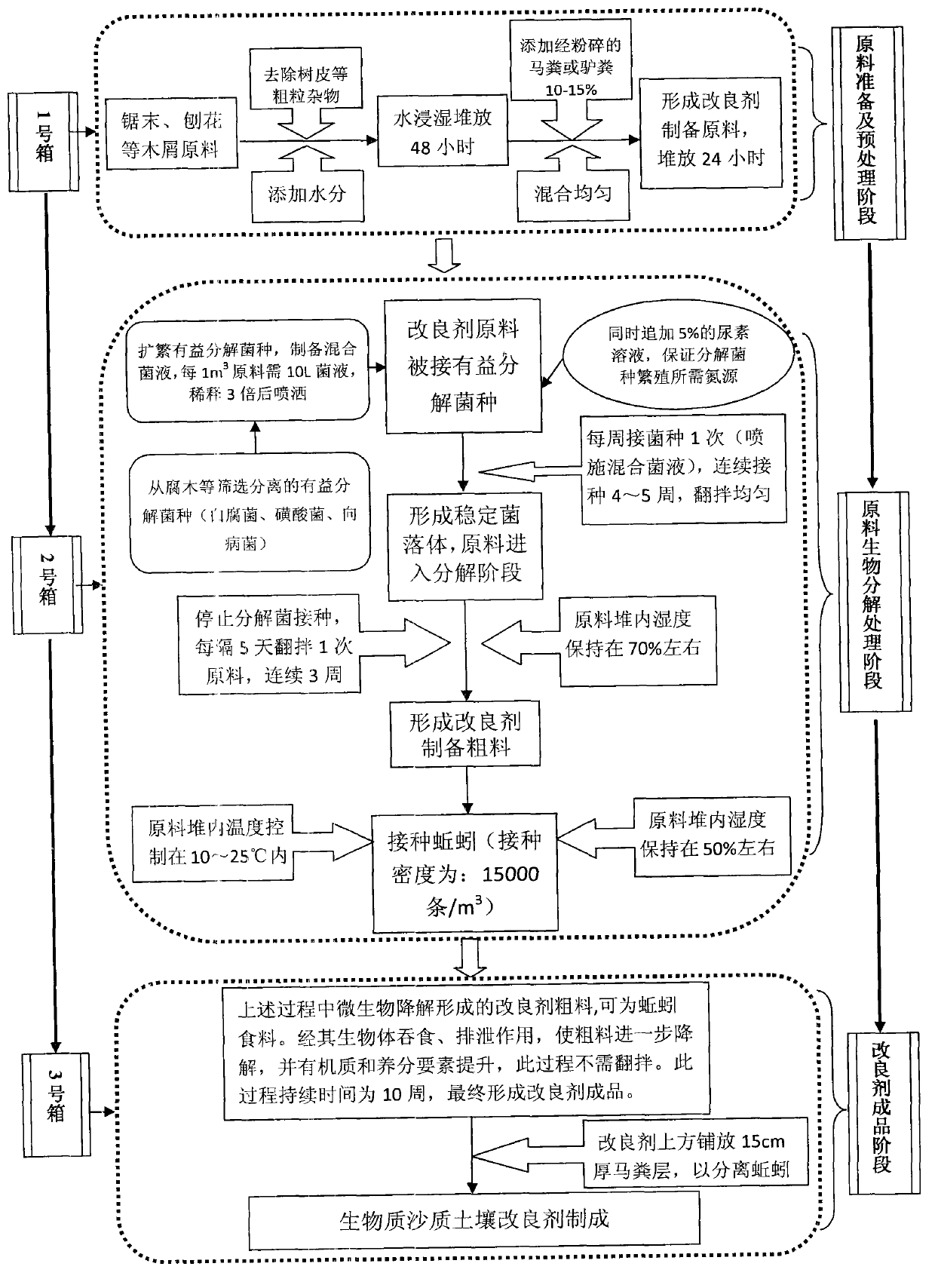

[0012] The preparation method of this biomass sandy soil improver, its technical process is:

[0013] (1) Required materials:

[0014] Main material: Wood waste, such as sawdust, wood shavings, dead branches and residues from wood processing plants, etc., if dead branches, etc. can be crushed into wood chips with a particle size of less than 5mm to shorten the decomposition cycle.

[0015] Accessory materials: horse, donkey, mule dung, can be properly crushed (not into a lump).

[0016] Decomposing bacteria: isolate and extract decomposing bacteria white rot fungi, sulfonic acid bacteria, and pathogenic bacteria with strong enzyme activity from fallen (rot) wood in nature.

[0017] (2) Decomposing bacteria culture method:

[0018] ① Mother liquor formula (per 1000ml solution) required chemical reagents: use glucose 20g, peptone 5g, magnesium sulfate (MgSO 4 ·7H 2 O) 1.5g, potassium dihydrogen phosphate (KH 2 PO 4 ) 1.5g, manganese sulfate (MnSO 4 )50mg, zinc sulfate (Zn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com