Method for preparing ultra-high purity difluoromono-chloroethane

A difluoro-monochloroethane, ultra-high-purity technology, applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, halogenated hydrocarbon disproportionation separation/purification, etc., can solve the problem of incomplete absorption of HCl and chlorine gas and incomplete reaction of raw materials , the problem of low product purity, to achieve the effect of inhibiting the formation of by-products, saving raw materials, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present invention prepares the method for ultrahigh-purity difluoro-chloroethane comprising the following steps:

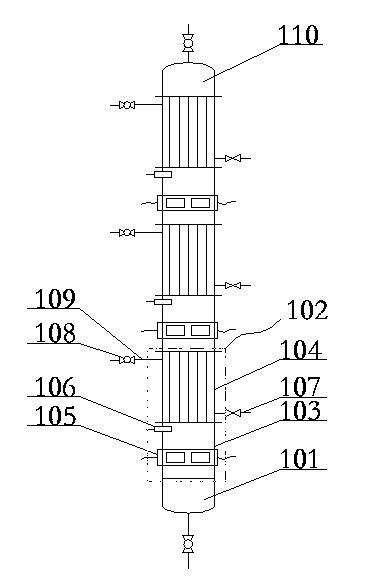

[0046] (1) Reaction: After the raw materials difluoroethane and liquid chlorine are gasified, they are mixed at a molar ratio of 1.15:1, and then enter the photochlorination reactor 1 for photochlorination reaction. The reaction temperature is 40°C, the reaction pressure is 0.05MPa, and the reaction residence time is 60S, the feeding amount of difluoroethane for a single photochlorination reactor is 100-150Kg / h;

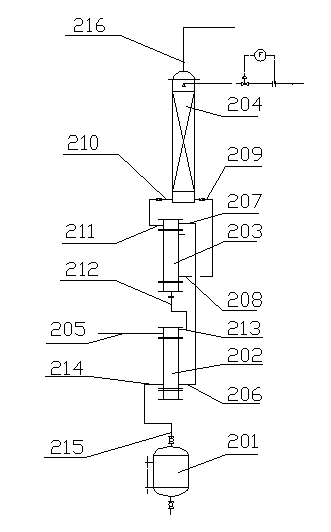

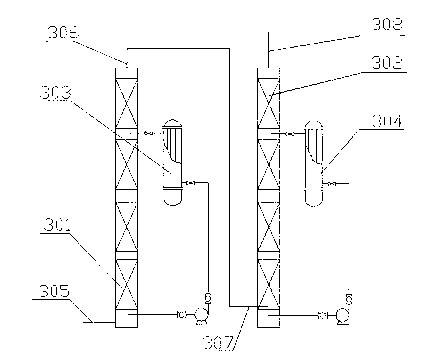

[0047] (2) Water washing: The gas reacted in the photochlorination reactor absorbs hydrogen chloride through the two-stage water absorption HCl tower 2, and the working pressure in the tower is 1.5MPa, the temperature in the tower is 40°C, and the absorbed HCl is dissolved in water Converted into hydrochloric acid with a concentration of 25-30%;

[0048] (3) Alkali washing: the gas after removing HCl is removed through the two-stage alkali li...

Embodiment 2

[0054] The present invention prepares the method for ultrahigh-purity difluoro-chloroethane comprising the following steps:

[0055] (1) Reaction: After the raw materials difluoroethane and liquid chlorine are vaporized, they are mixed at a molar ratio of 1.15:1, and enter the photochlorination reactor 1 for photochlorination reaction. The reaction temperature is 80°C, the reaction pressure is 0.1MPa, and the reaction residence time is 90S, the feed rate of difluoroethane for a single photochlorination reactor is 100-150Kg / h;

[0056] (2) Water washing: The gas reacted in the photochlorination reactor absorbs hydrogen chloride through the two-stage water absorption HCl tower 2, and the working pressure in the tower is 2.0MPa, the temperature in the tower is 80°C, and the absorbed HCl is dissolved in water Converted into hydrochloric acid with a concentration of 25-30%;

[0057] (3) Alkali washing: the gas after removing HCl is removed through the two-stage alkali liquid absor...

Embodiment 3

[0063] The present invention prepares the method for ultrahigh-purity difluoro-chloroethane comprising the following steps:

[0064] (1) Reaction: After the raw materials difluoroethane and liquid chlorine are vaporized, they are mixed at a molar ratio of 1.15:1, and then enter the photochlorination reactor 1 for photochlorination reaction. The reaction temperature is 60°C, the reaction pressure is 0.07MPa, and the reaction residence time is 70S, the feed rate of difluoroethane for a single photochlorination reactor is 100-150Kg / h;

[0065] (2) Water washing: The gas reacted in the photochlorination reactor absorbs hydrogen chloride through the two-stage water absorption HCl tower 2, and the working pressure in the tower is 1.7MPa, the temperature in the tower is 60°C, and the absorbed HCl is dissolved in water Converted into hydrochloric acid with a concentration of 25-30%;

[0066] (3) Alkali washing: the gas after removing HCl is removed through the two-stage alkali liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com