Production process of medicinal potassium citrate

The technology of potassium citrate and citrate ammonium salt is applied in the field of medicine and chemical industry, can solve the problem of low yield and the like, and achieve the effects of easy availability of raw materials, high production safety and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

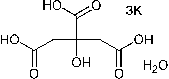

Image

Examples

Embodiment 1

[0041] 1. Weigh 5 kg of ammonium citrate salt, add 35 L of purified water, stir and raise the temperature to dissolve, and control the temperature at 50 °C to obtain triammonium citrate salt solution.

[0042] 2. Take the ammonium citrate solution and pass it through the HP-20 macroporous adsorption resin column. After the column is loaded, add water to fully elute to remove other impurities, and then use 31L of potassium carbonate solution with a concentration of 1.0% to elute , collect the eluate, concentrate under reduced pressure to 10L, and obtain potassium citrate concentrate.

[0043] 3. Take the concentrated solution, dilute it with water, add 20g of activated carbon, absorb, decolorize, and keep warm for 50 minutes. Connect the suction filtration device, and filter out activated carbon and trace impurities remaining in the solution through a coarse filtration (1 um) filter membrane. Then perform fine filtration (0.45um) and ultrafiltration (0.22um), and collect the f...

Embodiment 2

[0048] 1. Weigh 10kg of citric acid, add 70L of purified water, stir and heat up to dissolve, and control the temperature at 50°C to obtain a triammonium citrate solution.

[0049] 2. Take the triammonium citrate solution and pass it through the ion exchange resin column of model D301. After the column is loaded, add water to fully elute to remove other impurities, and then use 130L of potassium hydroxide solution with a concentration of 0.5% to elute. The eluate was collected and concentrated under reduced pressure to 18 L to obtain a concentrated solution of tripotassium citrate.

[0050] 3. Take the concentrated solution, add water to dilute appropriately, add 60g of activated carbon, absorb, decolorize, and keep warm for 70 minutes. Connect the suction filtration device, and filter out activated carbon and trace impurities remaining in the solution through a coarse filtration (1 um) filter membrane. Then perform fine filtration (0.45um) and ultrafiltration (0.22um), and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com