Method for recovering pyridine from pyridine hydrochloride water solution

A technology of pyridine hydrochloride and aqueous solution, which is applied in the chemical industry and can solve problems such as difficult separation, unsatisfactory pyridine recovery rate, and difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

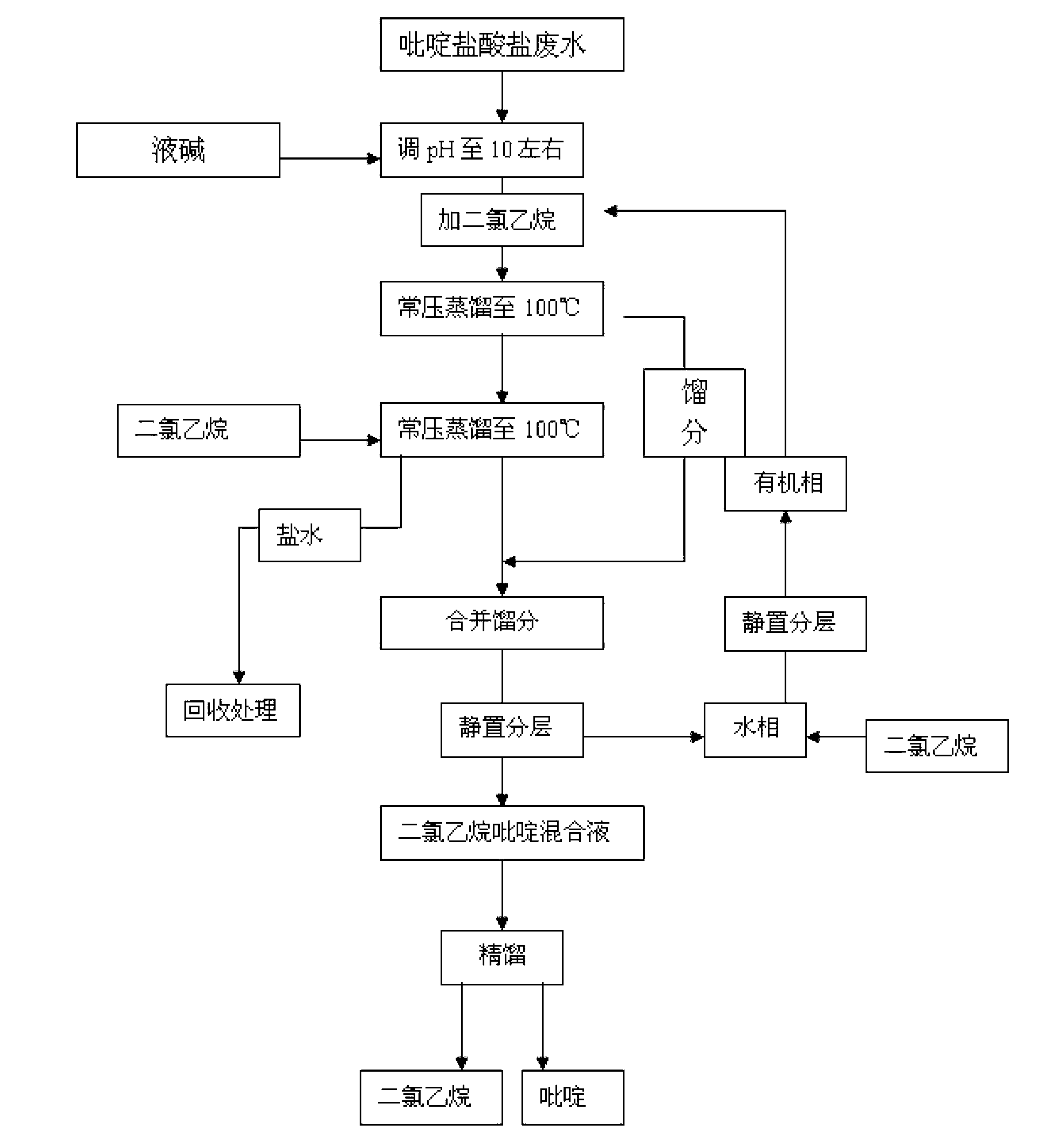

Image

Examples

Embodiment 1

[0027] Embodiment 1 reclaims pyridine from pyridine hydrochloride aqueous solution

[0028] Take 500 mL of an aqueous solution of pyridine hydrochloride with a specific gravity of 1.2000 g / mL and a pyridine content of about 14.5%, slowly add 30% NaOH solution under stirring, control the temperature at 55°C, adjust the pH to 10, and stir for 20 minutes to obtain the first solution;

[0029] Add 90 mL of dichloroethane into the first solution, stir it for 10 minutes, and then carry out the first atmospheric distillation, and stop at reflux to 100°C to obtain the first fraction of 194 mL, which is collected for later use;

[0030] Add 90 mL of dichloroethane to the distillation waste liquid of the first atmospheric distillation, and then carry out the second atmospheric distillation after stirring for 10 minutes, and stop at reflux to 100 ° C to obtain the second fraction 139 mL, and combine the first fraction with the second The two fractions are mixed to obtain the second solut...

Embodiment 2

[0033] Embodiment 2 reclaims pyridine from pyridine hydrochloride aqueous solution

[0034] Take 500mL of pyridine hydrochloride aqueous solution with a specific gravity of 1.2000g / mL (pyridine hydrochloride aqueous solution is the waste liquid produced by the preparation of bentazon), the content of pyridine is about 10%, slowly add 50% NaOH solution under stirring, and the temperature is controlled at 60°C , adjust the pH to 10, and stir for 20 minutes to obtain the first solution;

[0035] Add 64mL of dichloroethane into the first solution, stir it for 10 minutes, then carry out the first atmospheric distillation, and stop at reflux to 100°C to obtain the first fraction of 138mL, which is collected for later use;

[0036] Add 64mL of dichloroethane to the distillation waste liquid of the first atmospheric distillation, and then carry out the second atmospheric distillation to it after stirring for 10 minutes, and return to 98°C to stop to obtain the second fraction 99mL, an...

Embodiment 3

[0039] Embodiment 3 reclaims pyridine from pyridine hydrochloride aqueous solution

[0040] Take 500 mL of an aqueous solution of pyridine hydrochloride with a specific gravity of 1.2000 g / mL and a pyridine content of about 20%, slowly add 30% NaOH solution under stirring, control the temperature at 57°C, adjust the pH to 9, and stir for 20 minutes to obtain the first solution;

[0041] Add 127mL of dichloroethane to the first solution, stir it for 10 minutes, then carry out the first atmospheric distillation, and stop at reflux to 100°C to obtain the first fraction of 274mL, which is collected for later use;

[0042] Add 127mL of dichloroethane to the distillation waste liquid of the first atmospheric distillation, and then carry out the second atmospheric distillation to it after stirring for 10 minutes, return to 100°C to stop, and obtain the second fraction 196mL, and combine the first fraction with the second The two fractions are mixed to obtain the second solution for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com