Preparation method of tri(dimethylamino)borane

A technology of dimethylamino and borane, applied in the field of preparation, can solve the problems of high toxicity, difficult transportation and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

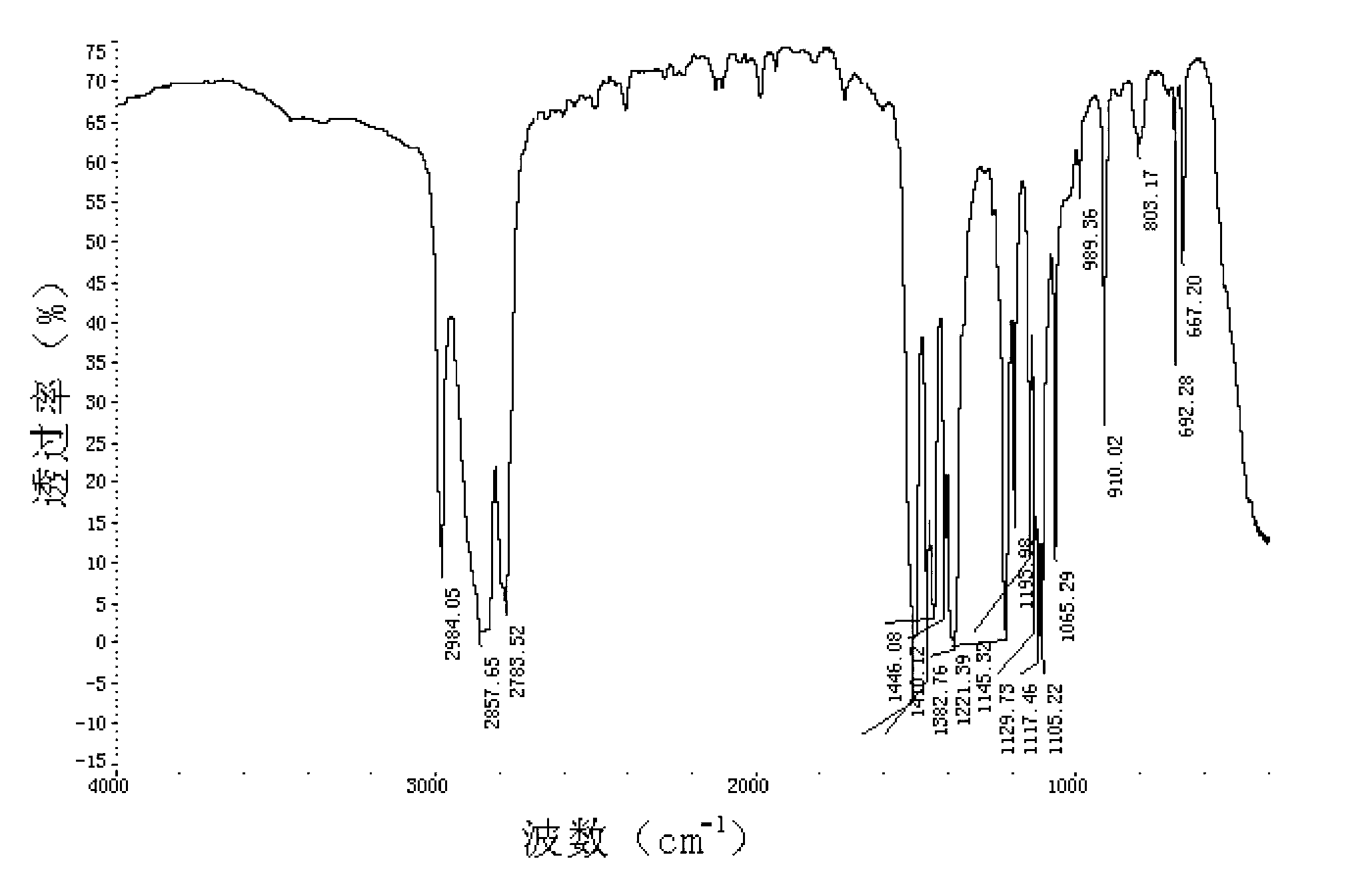

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of tris(dimethylamino)borane in this embodiment is specifically prepared according to the following steps:

[0017] 1. According to the material ratio of boron trihalide, dimethylamine salt and alkali as 1:6~12:6~18, weigh the organic solution of boron trihalide and dimethylamine with a mass concentration of 15%~30%. Salt and alkali solution with mass concentration of 30%~60%;

[0018] 2. Add the alkali solution weighed in step 1 into the dimethylamine salt at room temperature under stirring conditions to obtain dimethylamine gas, and control the stirring speed to 50r / min~800r / min;

[0019] Three, the dimethylamine gas that step 2 obtains is passed through potassium hydroxide drier, obtains the dimethylamine gas of drying;

[0020] 4. At a temperature of -20°C~5°C, pass dry dimethylamine gas into the continuously stirring boron trihalide organic solution, then continue stirring for 1h~1.5h, and control the stirring speed ...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the ratio of boron trihalide, dimethylamine salt and alkali in step 1 is 1:7~10:9~15. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass concentration of the boron trihalide organic solution in step 1 is 18%-25%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com