Jatropha curcas source environment disinfectant and preparation method thereof

The technology of a disinfectant and tung seeds source, applied in the field of biotechnology, can solve the problems of high oil content of Jatropha japonica seed kernels, no patent reports, etc., and achieve broad industrialization and market application prospects, and the extraction process is simple and the process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

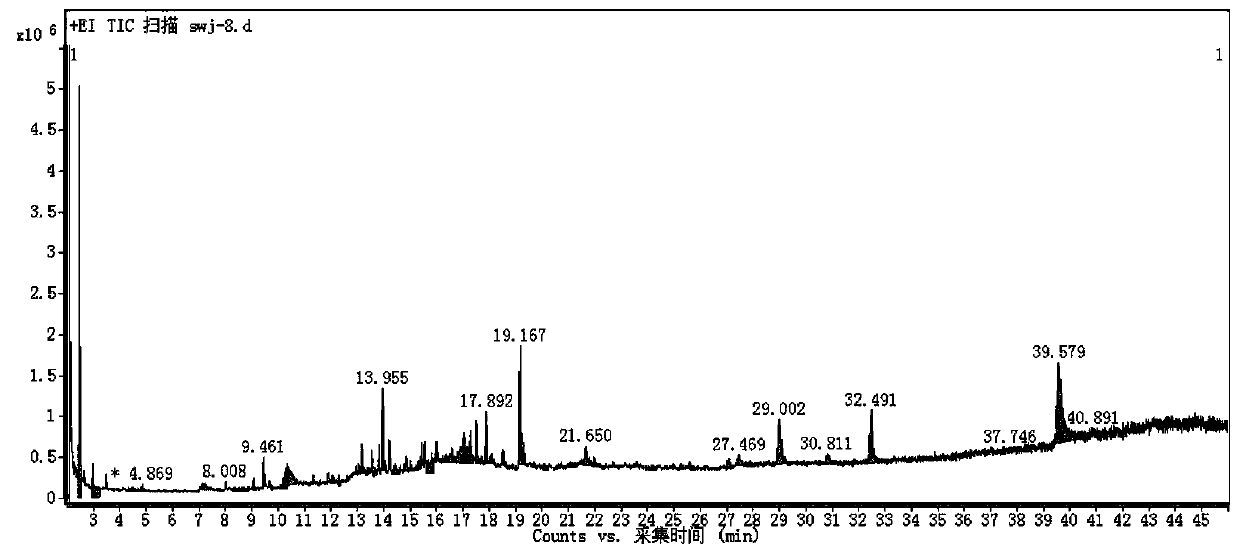

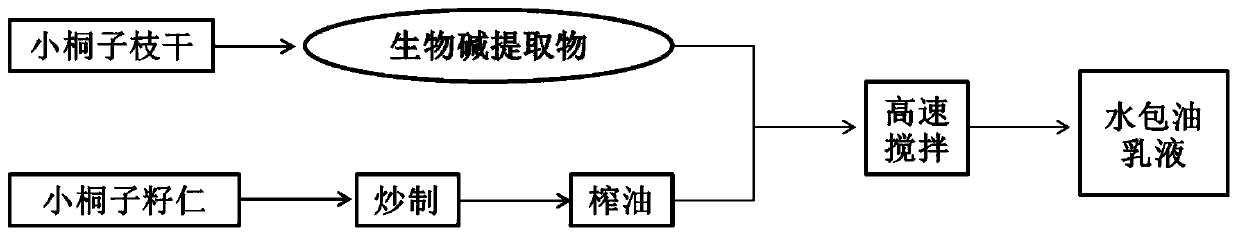

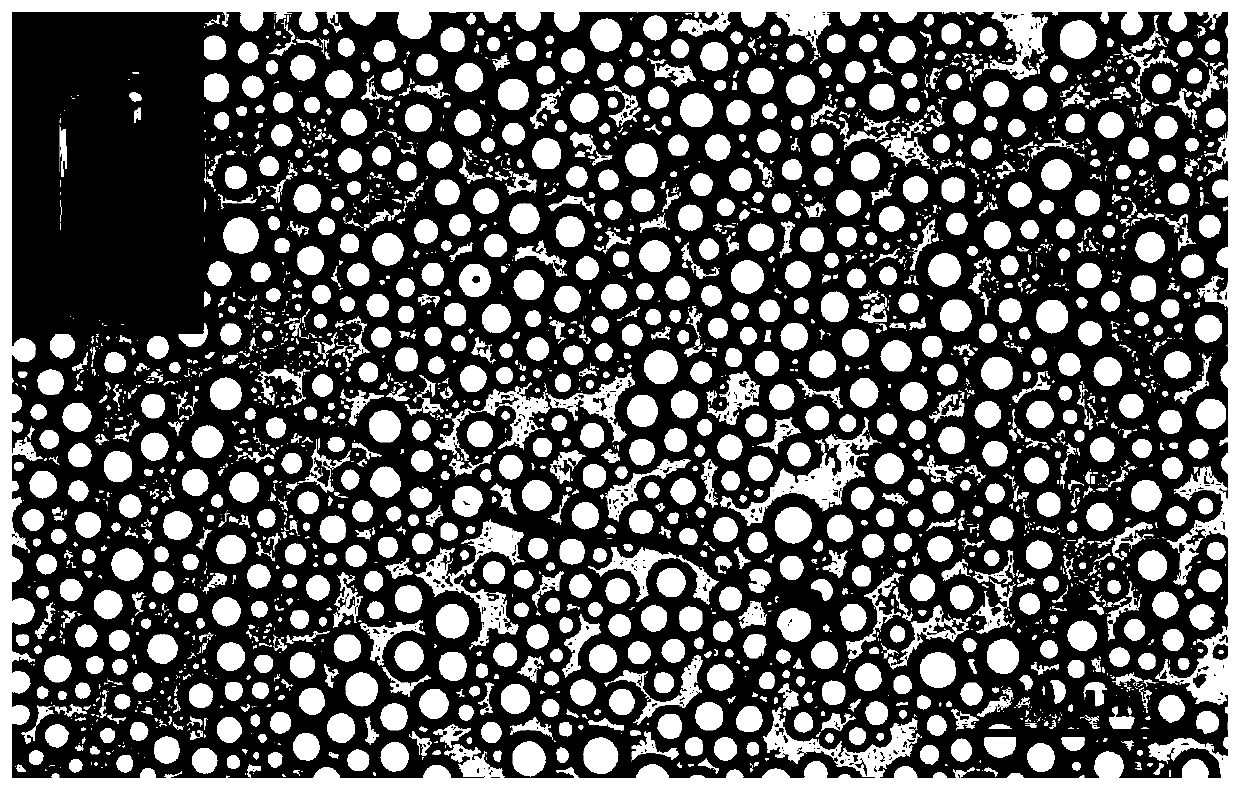

[0033] Such as figure 2 As shown, Step A: Dissolve the alkaloid extract extracted from Jatropha Jatropha leaves in dichloromethane at 25°C, and use n-octane / ethyl acetate (volume ratio 3:1) in a 400-mesh chromatography silica gel column The mixed solvent was rinsed for 15 h, and the eluent was rotary evaporated to obtain N-substituted phenylacetamide. Add 20.5Kg of the alkaloid extract N-substituted phenylacetamide extracted from Jatropha jatropha branches to 15.6Kg of vegetable oil squeezed from the Jatropha seed kernel, stir at 20°C for 10min to dissolve the alkaloid extract and obtain a uniform The oil phase mixture a, stirring speed 3000r / min.

[0034] Step B: Add 5Kg of surfactant sodium dodecylbenzenesulfonate and 0.5Kg of co-surfactant lauryl alcohol into the above-mentioned phase oil mixture a, stir at 3000r / min for 5min to obtain a homogeneous oil phase mixture b.

[0035] Step C: 58.4Kg of water is gradually added to the above-mentioned uniform oil phase mixture b...

Embodiment 2

[0038]Step A: Dissolve the alkaloid extract mixture extracted from Jatropha Jatropha leaves in dichloromethane at 28°C, and use a mixed solvent of ether / cyclohexane (volume ratio 2:1) in a 300-mesh chromatography silica gel column Rinse for 30 h, and then evaporate the eluent by rotary evaporation to obtain 6-diethylaminobenzofuran-3-one. Add 30.2Kg of the alkaloid extract 6-diethylaminobenzofuran-3-one extracted from the branches of Jatropha Jatropha to 27.3Kg of vegetable oil squeezed from Jatropha Jatropha seeds, and stir at 24°C for 15 minutes to extract the alkaloids The substance is dissolved and a homogeneous oil phase mixture a is obtained, and the stirring speed is 4000r / min.

[0039] Step B: Add 10Kg of surfactant polyvinylpyrrolidone and 2Kg of co-surfactant ethylene glycol into the above-mentioned phase oil mixture a, stir at 4000r / min for 7min to obtain a homogeneous oil phase mixture b.

[0040] Step C: 30.2Kg of water is gradually added to the above-mentioned u...

Embodiment 3

[0043] Step A: Dissolve the alkaloid extract mixture extracted from Jatropha Jatropha leaves in chloroform at 40°C, and use a mixed solvent of tetrahydrofuran / cyclohexane (volume ratio 2:1) in a 300-mesh chromatography silica gel column Rinse for 36 hours, and then rotate the eluate to obtain tetrahydroisoquinoline derivatives. Add 25.0Kg of the alkaloid extract tetrahydroisoquinoline derivatives extracted from Jatropha Jatropha branches to 34.2Kg of vegetable oil squeezed from Jatropha Jatropha seeds, stir at 25°C for 18 minutes to dissolve the alkaloid extract and obtain a uniform The oil phase mixture a, stirring speed 4500r / min.

[0044] Step B: Add 8Kg of surfactant polyvinyl alcohol and 1Kg of co-surfactant polyethylene glycol into the above phase oil mixture a, stir at 4500r / min for 8min to obtain a homogeneous oil phase mixture b.

[0045] Step C: 31.8Kg of water was gradually added to the above-mentioned uniform oil phase mixture b, and then stirred at a high speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com