Polyurethane resin for tetramethylguanidine ionic liquid-modified waterborne synthetic leather and manufacturing method thereof

A tetramethylguanidine type, polyurethane resin technology, used in textiles and papermaking, etc., can solve the problems of waterborne polyurethane mechanical strength, poor solvent resistance and water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

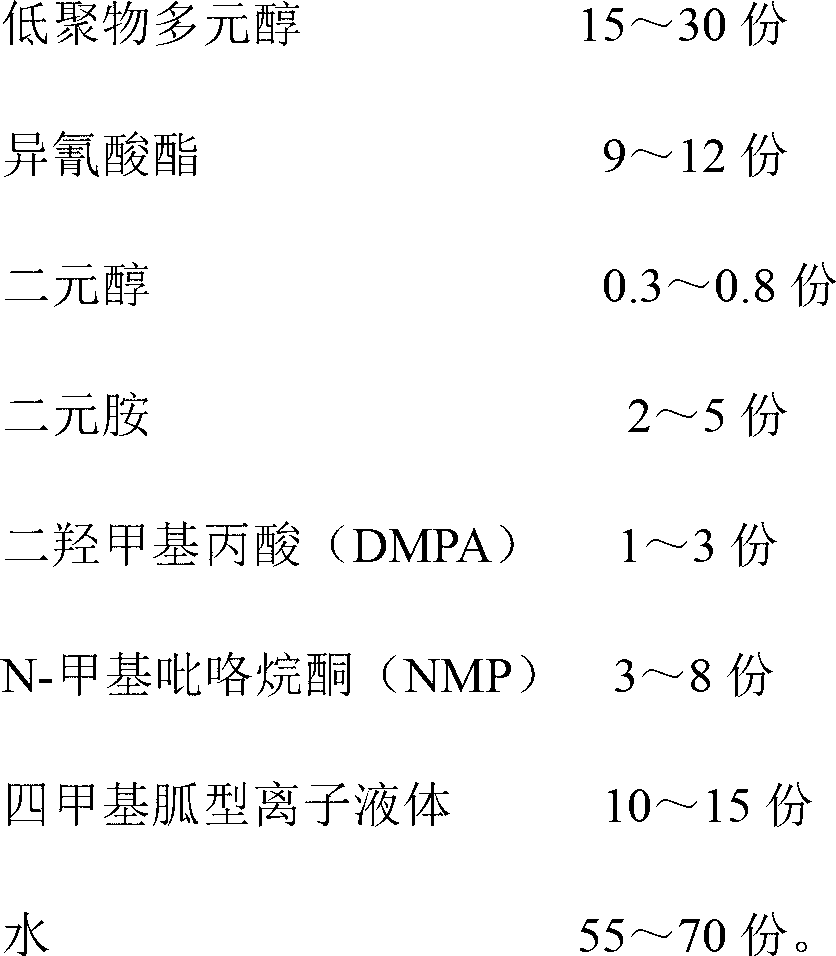

[0024]

[0025]

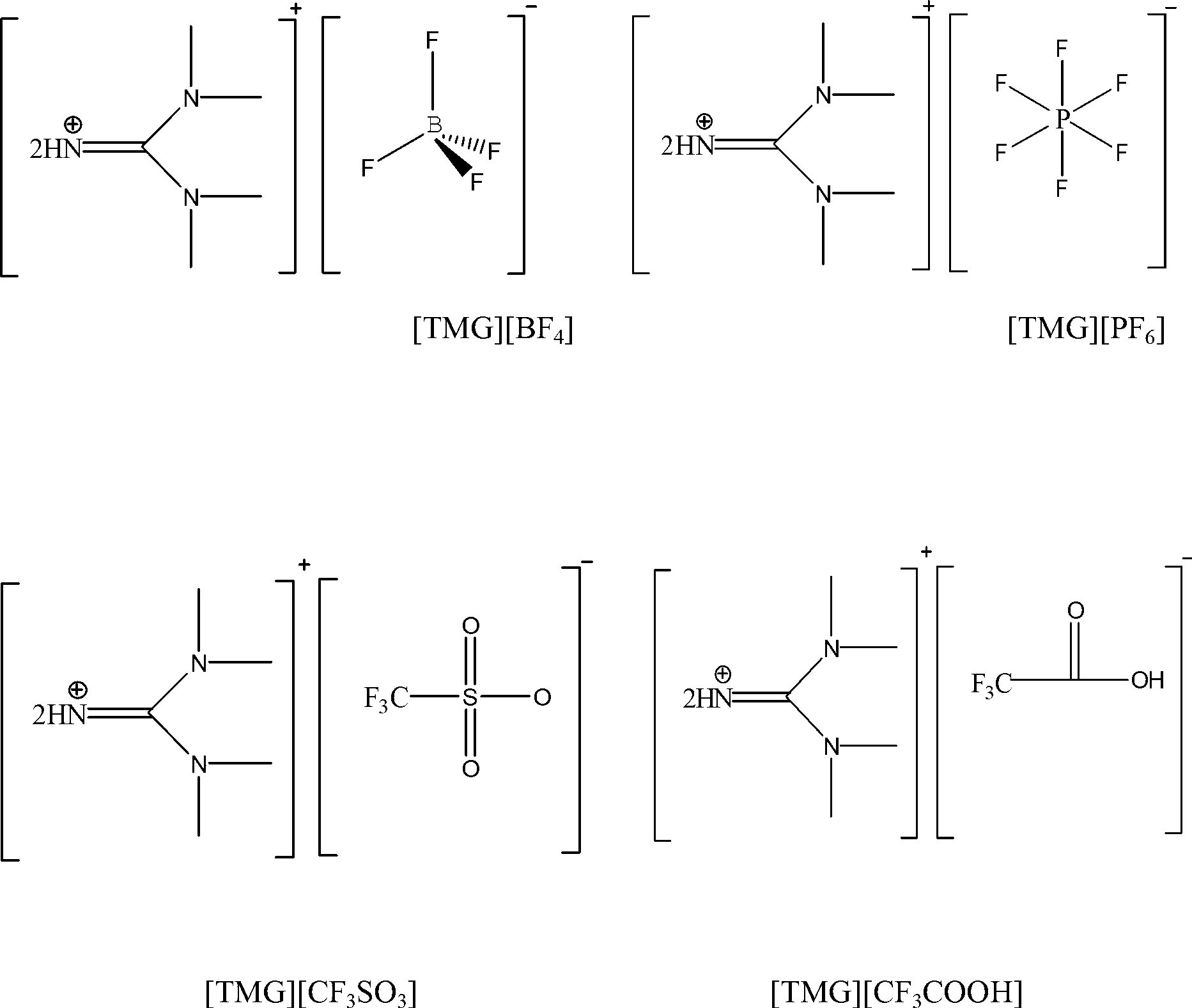

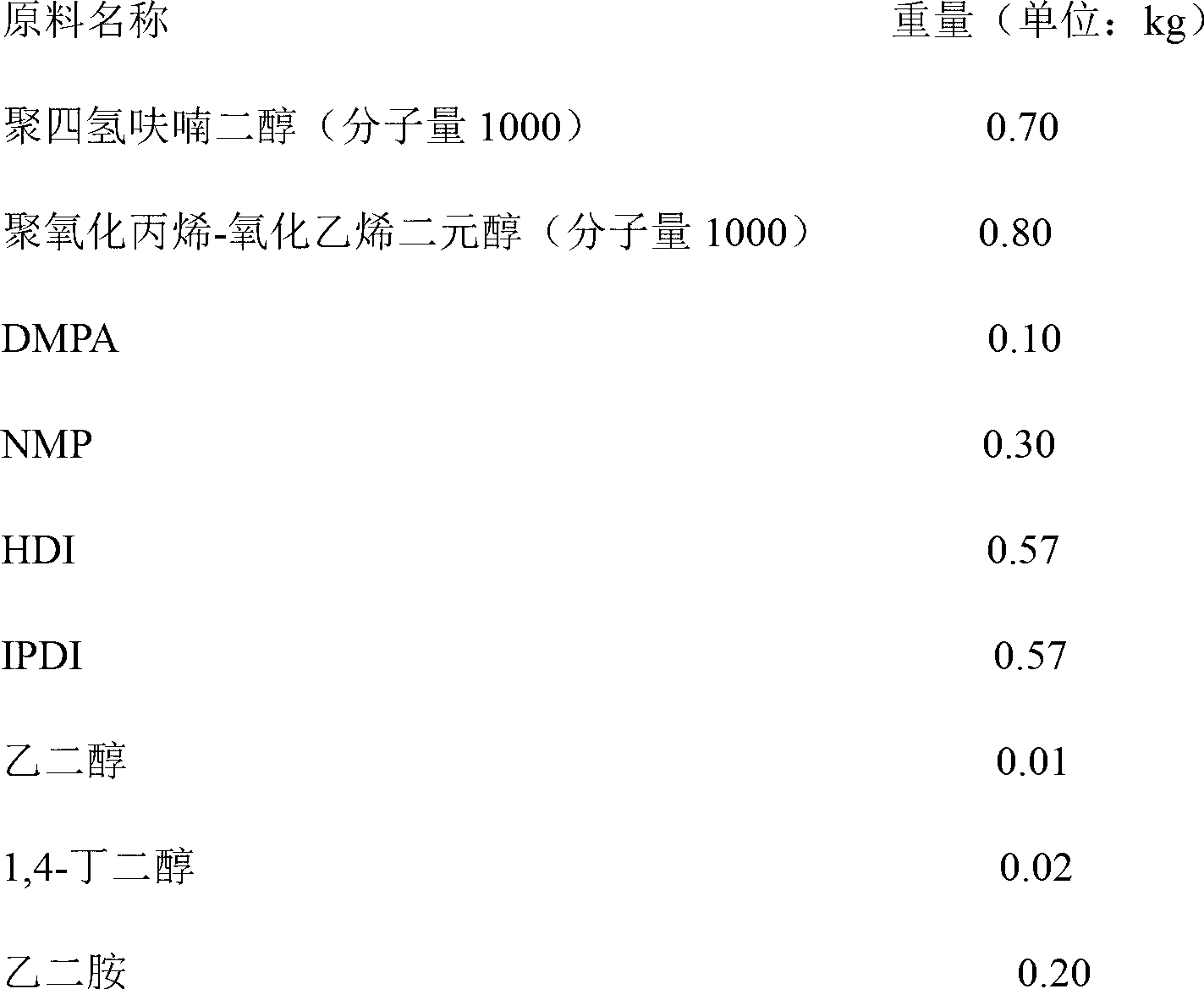

[0026] Add polytetrahydrofuran diol, polyoxypropylene-oxyethylene glycol, DMPA, NMP into a reactor equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen protection device, raise the temperature to 60°C, and slowly add MDI after 50 minutes. React at 90°C for 4 hours, add ethylene glycol and 1,4-butanediol, react for 2 hours, add deionized water, stir vigorously, add ethylenediamine dropwise, control the dropping time at 30 minutes, and stir for 50 minutes after the addition , and finally join [TMG][BF 4 ] and [TMG][PF 6 ] reacted for 50 minutes to obtain the product.

[0027] The industry standard "QB / T4197-2011 Polyurethane Resin for Synthetic Leather" was used for testing, and the results are as follows:

[0028] Solid content: 45%;

[0029] Abrasion resistance: 800r without damage;

[0030] Tensile strength / MPa: 46.0;

[0031] Elongation: 1100%;

[0032] Water absorption (soaked in distilled water for 24 hours): 8.8%.

Embodiment 2

[0034]

[0035]

[0036] Add polytetrahydrofuran diol, polyoxypropylene-oxyethylene glycol, DMPA, NMP into a reactor equipped with a stirrer, thermometer, reflux condenser, and nitrogen protection device, raise the temperature to 65°C, and slowly add MDI after 45 minutes. React at 95°C for 3.5 hours, add ethylene glycol and 1,4-butanediol, react for 1.5 hours, add deionized water, stir vigorously, add ethylenediamine dropwise, control the dropping time at 40 minutes, stir after the addition is complete 40 minutes, add [TMG][BF at the end 4 ] and [TMG][PF 6 ] reacted for 40 minutes to obtain the product.

[0037] The industry standard "QB / T4197-2011 Polyurethane Resin for Synthetic Leather" was used for testing, and the results are as follows:

[0038] Solid content: 40%;

[0039] Abrasion resistance: 900r without damage;

[0040] Tensile strength / MPa: 46.5;

[0041] Elongation: 1060%;

[0042] Water absorption (soaked in distilled water for 24 hours): 8.5%.

Embodiment 3

[0044]

[0045]

[0046] Add polytetrahydrofuran diol, polyoxypropylene-oxyethylene glycol, DMPA, NMP into a reactor equipped with a stirrer, a thermometer, a reflux condenser, and a nitrogen protection device, raise the temperature to 70°C, and slowly add MDI after 40 minutes. React at 100°C for 2.5 hours, add ethylene glycol and 1,4-butanediol, react for 1.5 hours, add deionized water, stir vigorously, add ethylenediamine dropwise, control the dropping time at 50 minutes, stir after the addition is complete 40 minutes, add [TMG][BF at the end 4 ] and [TMG][PF 6 ] reacted for 40 minutes to obtain the product.

[0047] The industry standard "QB / T4197-2011 Polyurethane Resin for Synthetic Leather" was used for testing, and the results are as follows:

[0048] Solid content: 35%;

[0049] Abrasion resistance: 900r without damage;

[0050] Tensile strength / MPa: 47.0;

[0051] Elongation: 1000%;

[0052] Water absorption (soaked in distilled water for 24 hours): 8.8%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com