Preparation method for moisture-absorbing and flame-retardant polyester fiber

A copolyester, flame retardant technology, applied in the field of composite functional polyester fibers, can solve problems such as poor flame retardant durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

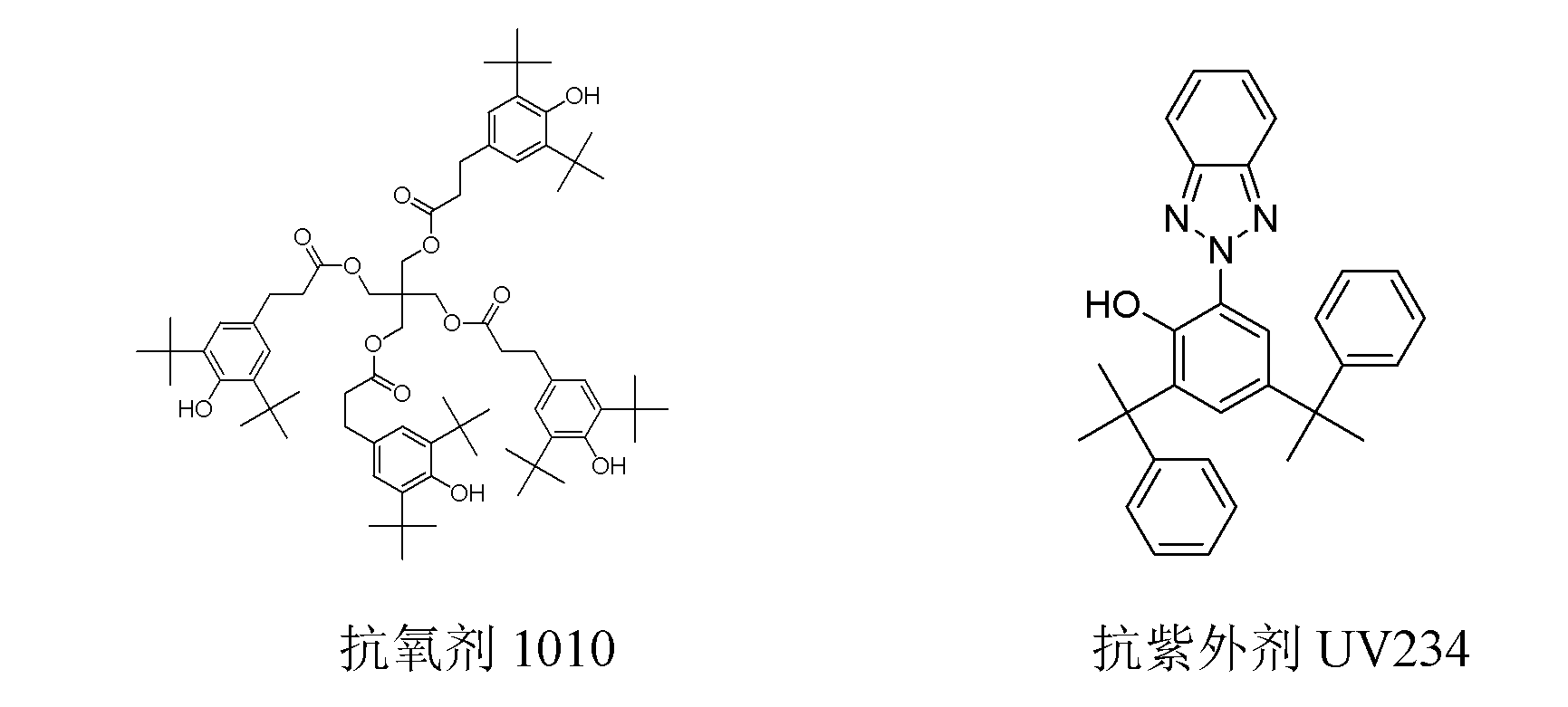

Method used

Image

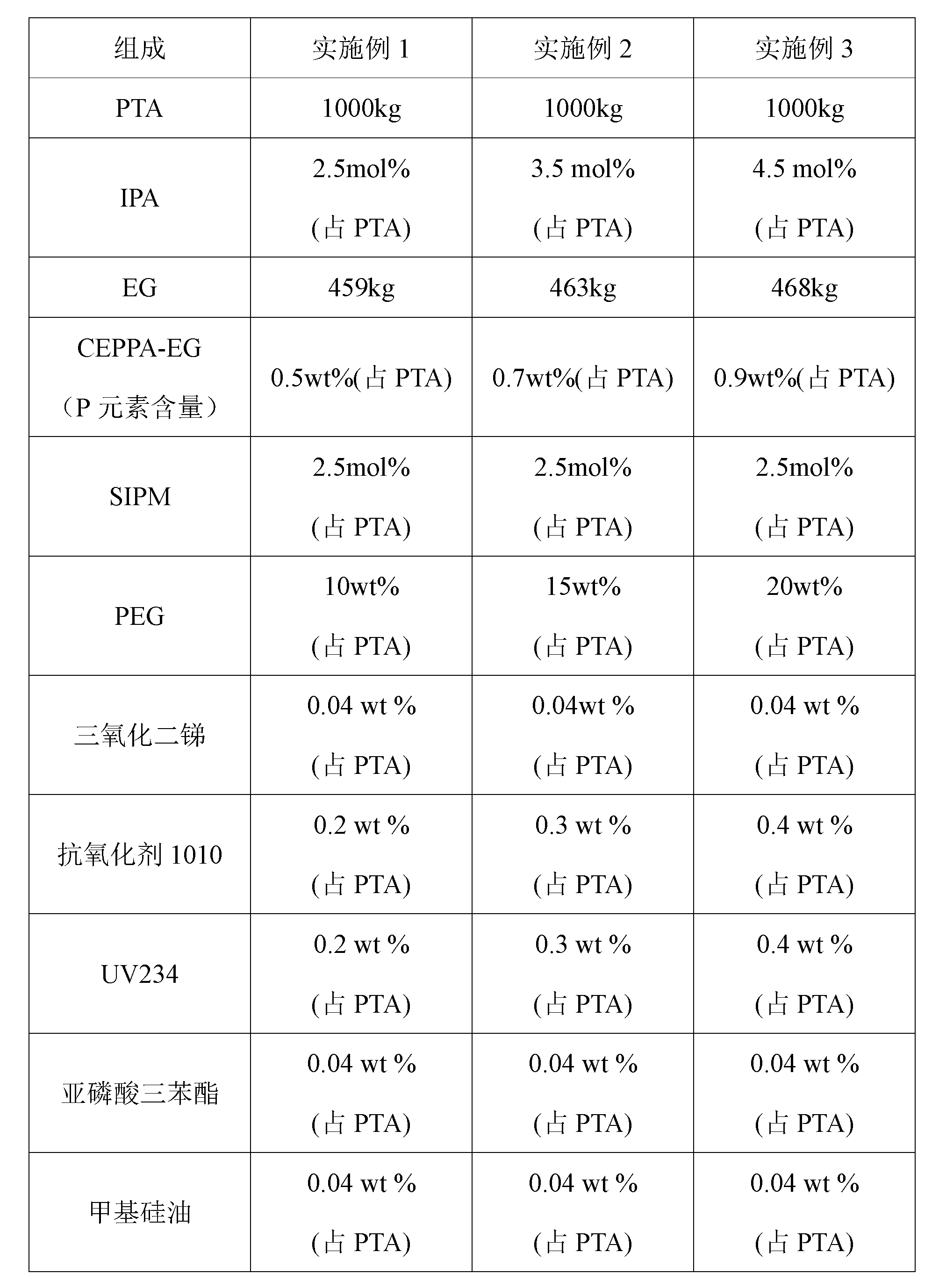

Examples

Embodiment Construction

[0025] The present invention will be further described by the following examples, obviously the present invention is not limited only to the following examples. (The embodiment feels that the writing is not clear enough to clearly explain the content of the inventive technology. It is recommended to explain the steps in detail)

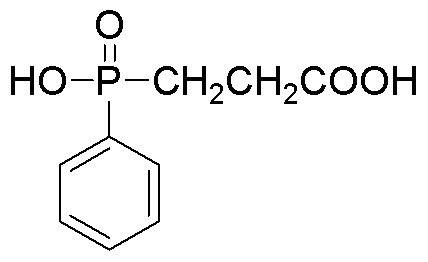

[0026] 1. Pre-esterification of CEPPA

[0027] Feed CEPPA and EG at a molar ratio of 1:2, raise the temperature of EG to 120±2°C in advance, then add white crystalline solid flame retardant (CEPPA), stir at this temperature for 3.0h to carry out esterification reaction, The reaction product is transported to the storage tank for use.

[0028] 2. Esterification and polycondensation reaction

[0029] Using ethylene glycol (EG) and terephthalic acid (PTA) and a certain amount of isophthalic acid (IPA) (EG: (PTA+IPA)=1.2:1, molar ratio) as raw materials, in the direct esterification unit At 255°C, at the same time, add CEPPA esterification solution in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com