Flame-retardant glass fiber-reinforced ABS/PA6/PA66 alloy material with high CTI value and high GWIT value

A technology of alloy materials and glass fiber, which is applied in the field of ABS/PA6/PA66 alloy materials, can solve the problems of unsuitable electricity environment, low CTI value and GWIT value, etc., to improve oxidation resistance, improve processing fluidity, prevent The effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

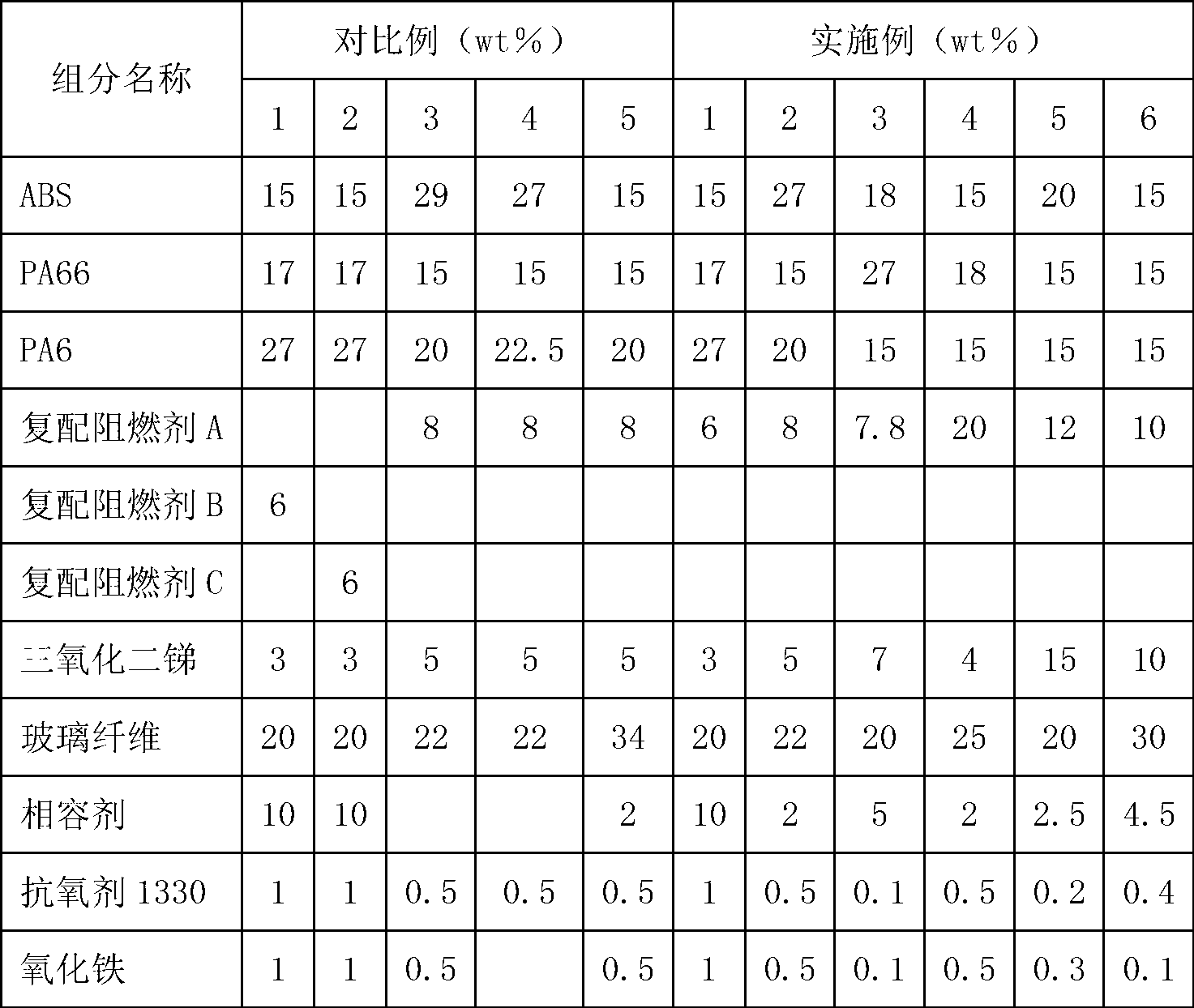

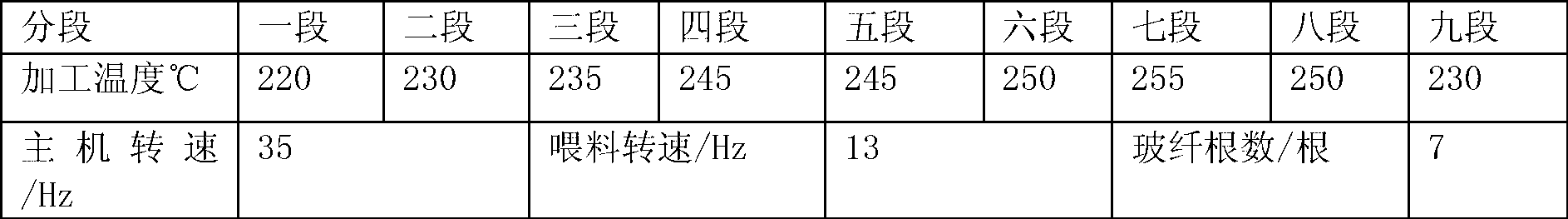

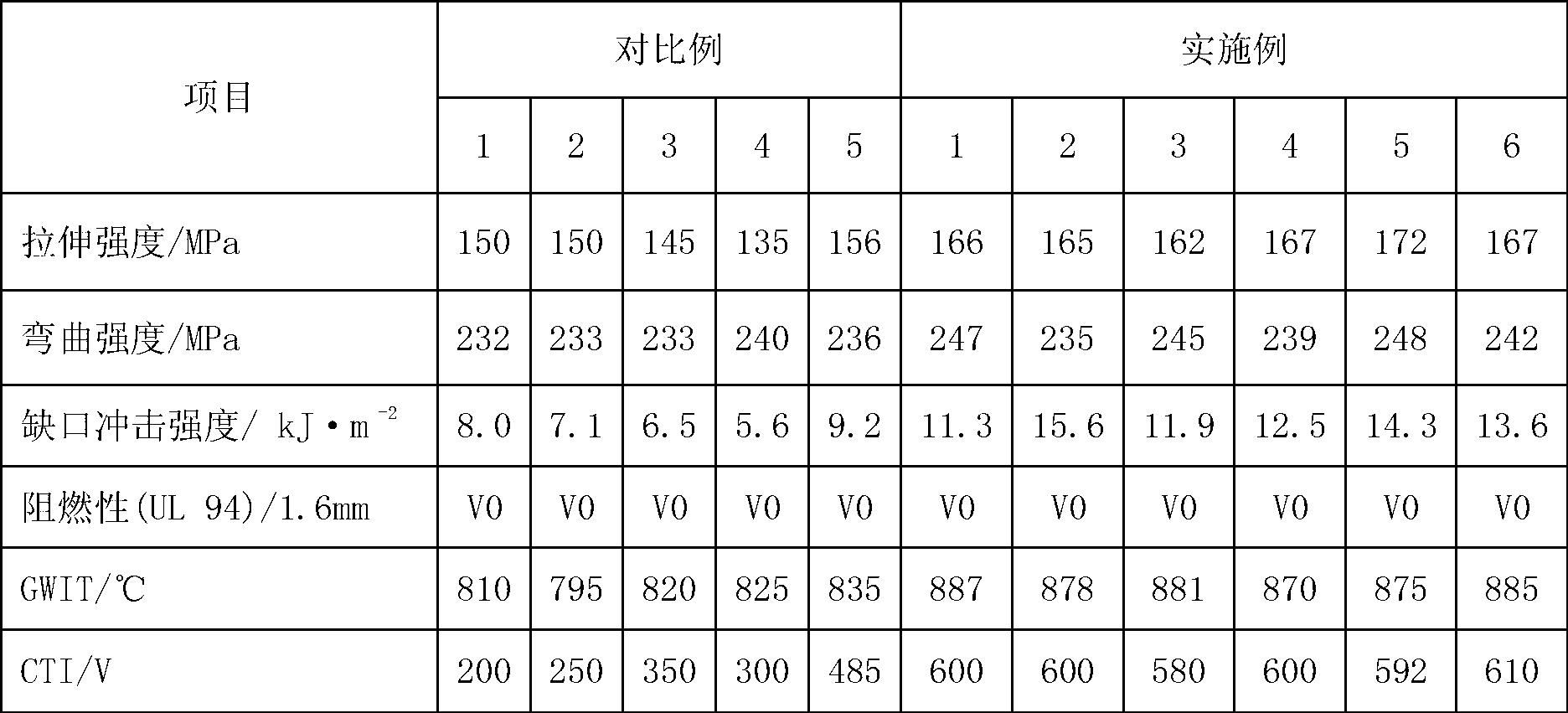

[0031] The high CTI value, high GWIT value flame-retardant glass fiber reinforced ABS / PA6 / PA66 alloy material of Examples 1-6, each component contained is shown in Table 1, wherein, ABS is commercially available acrylonitrile-butadiene- Styrene, PA66 is a commercially available polyhexamethylene adipamide with an intrinsic viscosity of 2.8dl / g, PA6 is a commercially available polyamide 6 with an intrinsic viscosity of 2.8dl / g, and the glass fiber is treated with a silane coupling agent on the surface Alkali-free glass fiber (specifically: add the non-alkali glass fiber to the silane coupling agent to make the surface treated with the silane coupling agent), the compatibilizer is commercially available maleic anhydride grafted ABS, and compound the flame retardant A It is composed of three components, its mass percentage is BPS: 50%, magnesium hypophosphite: 25%, talcum powder: 25%, compound flame retardant B is BPS, GF with a mass ratio of 2:1:1 (Non-reactive flame retardant c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com